Making adjustments to your saw, Adjusting your saw – SawStop CNS175-AU User Manual

Page 75

SawStop 10” Contractor Saw 73

Adjusting

Your Saw

Making Adjustments to Your Saw

Adjusting the Quick-Release Clamp

The clamping pressure holding the spreader or riving knife in the quick-release clamp is factory adjusted to

require approximately 5-10 lbs. of force to push the handle to the fully down and clamped position. This is a

moderate amount of force to apply with one hand. If excessive force is required to move the handle down, or if

you are unable to move the handle down by hand, then the clamp should be adjusted to reduce the clamping

pressure. Alternatively, if the handle moves down with only light pressure, then the clamping force should be

increased. When evaluating the clamping force, make sure the riving knife or spreader is properly seated in

the clamp.

To adjust the clamping force, begin by removing the riving knife or spreader. Raise the handle so that it faces

upward, and push the handle toward the clamp. The clamp assembly includes an internal spring designed to

push the clamp open when the handle is raised. Therefore you will have to push the handle toward the clamp

against the force of the spring.

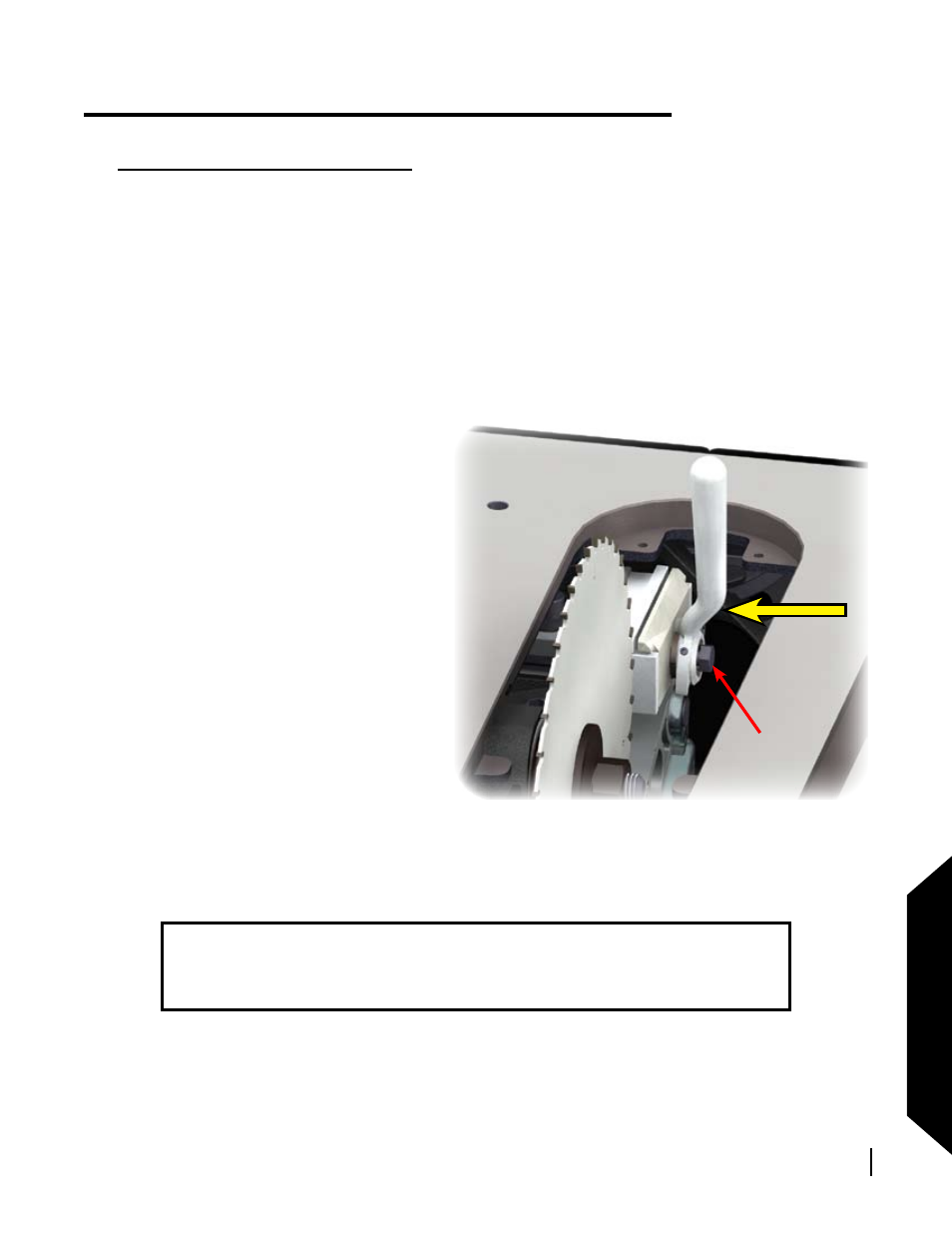

When the handle is fully pressed against the

clamp, an adjustment bolt will be exposed

as shown in Fig. 99. Turn the adjustment

bolt clockwise a slight amount to increase

the clamping pressure, or counter-clockwise

a slight amount to decrease the clamping

pressure. Release the handle and allow the

spring to push it away from the clamp and

re-engage the adjustment bolt. Now reinstall

the spreader or riving knife and test the

clamping pressure. Repeat the adjustment as

necessary until the correct clamping pressure

is achieved.

WARNING! It is important to maintain the correct clamping pressure on the riving knife

and spreader. If the pressure is too low these important safety devices may not function

properly and a serious injury could result. In addition, the spreader or riving knife may come

into contact with the blade and cause an unintended activation of the safety system.

adjustment

bolt

push handle

toward clamp

Fig. 99