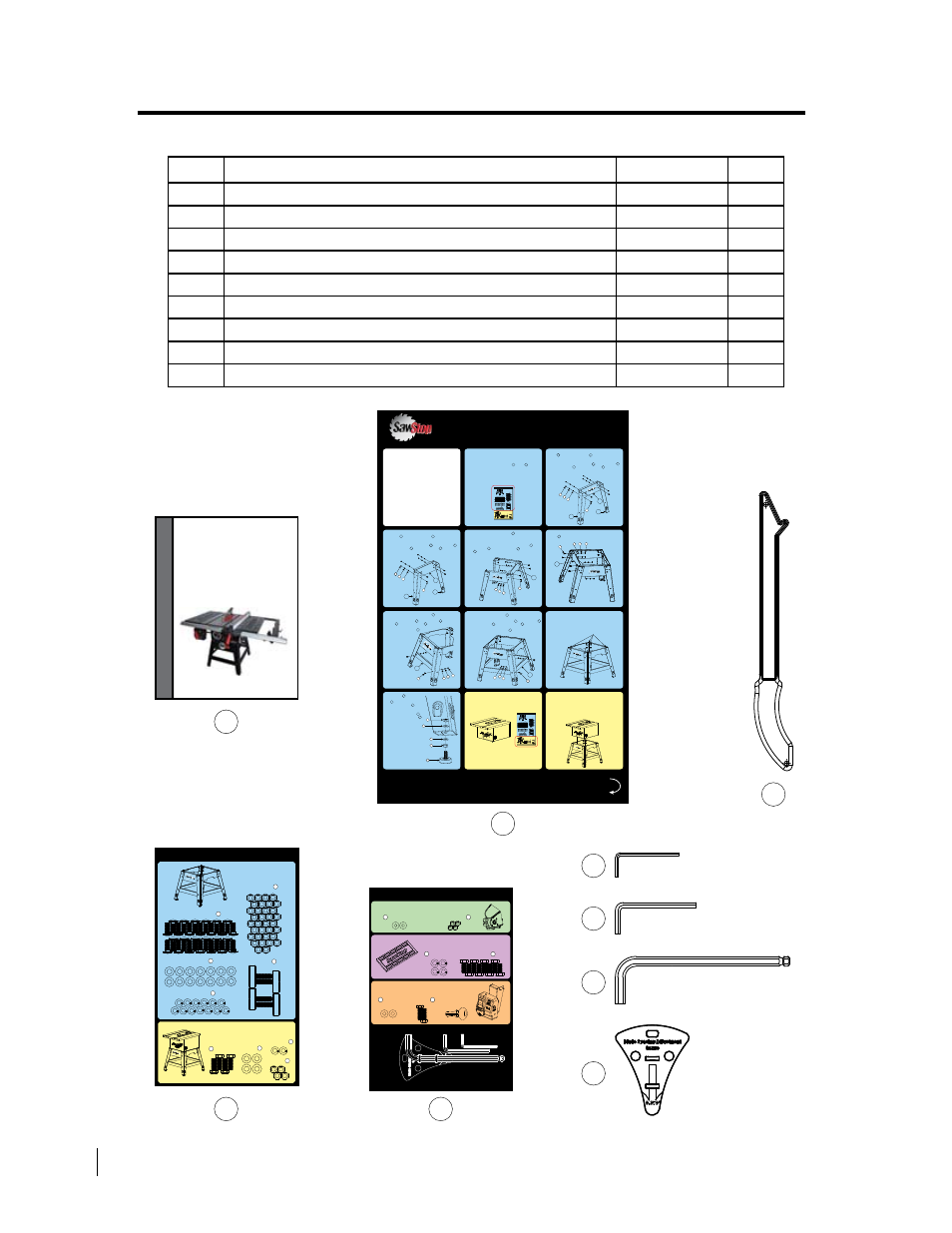

Literature, hardware and tools parts list, Sawstop, No. description part no. qty – SawStop CNS175-AU User Manual

Page 104: 10” contractor saw

102

SawStop 10” Contractor Saw

Literature, Hardware and Tools Parts List

No.

Description

Part No.

Qty.

1

SawStop 10” Contractor Saw Owner’s Manual

CNS-10-005

1

2

Assembly Instructions Poster

CNS-07-248

1

3

Push Stick

CNS-10-007

1

4

Hardware Pack #1

CNS-07-250

1

5

Hardware Pack #2 (includes items 6-9)

CNS-07-251

1

6

3 mm Hex Key

CB104 268

1

7

5 mm Hex Key

CB104 269

1

8

8 mm Hex Key Ball End

CB104 270

1

9

Blade Spacing Adjustment Gauge

CNS-07-255

1

OWNER’S MANUAL

10” CONTRACTOR SAW

SawStop

®

1

2

3

4

5

6

7

8

9

Assembling Your SawStop Contractor Saw

SawStop Service Department

503-582-9934

www.sawstop.com

Before assembling your saw, make sure that you

have all the components identified on pages 12 and

13 in the Owner’s Manual, including hardware

pack #1 and hardware pack #2. Call the SawStop

Service Department at 503-582-9934 if any

components are missing. Hardware pack #2

includes some of the tools needed to assemble

the saw. You will also need the following additional

tools:

1. an 8 mm socket

2. a 10 mm wrench

3. two 13 mm wrenches

4. a level or straight edge

Assembling the Stand

1

• Locate the stand components labeled through and

hardware pack #1. All of the hardware needed to assemble the

stand is located in the area with the blue background on

hardware pack #1. In order to easily identify the hardware used

in each of the following steps, the different pieces of hardware

are numbered on the hardware pack and on these assembly

instructions.

A

F

2

• Assemble the front of the stand by attaching two of the legs

marked to the front panel marked . Make sure that the legs

are in front of the front panel. Bumps on the legs fit into holes in

the front panel to align the legs. Attach the legs to the front

panel using four M8 x 20 carriage bolts , four M8 washers ,

four M8 lock washers , and four M8 hex nuts . Do

not fully

tighten the nuts at this time. Leaving the nuts loose will make it

easier to align holes as you assemble the rest of the stand.

4

3

2

1

A

B

A

B

1

2

3

4

A

3

4

3

2

1

• Assemble the rear of the stand by attaching the remaining two

legs marked to the rear panel marked . Make sure that the

legs are in front of the rear panel. Bumps on the legs fit into holes

in the rear panel to align the legs. Attach the legs to the rear

panel using four M8 x 20 carriage bolts , four M8 washers ,

four M8 lock washers , and four M8 hex nuts . Do

not fully

tighten the nuts at this time.

A

C

A

C

A

1

2

3

4

4

• Attach one of the side panels marked between the front and

rear portions of the stand. Make sure the legs are in front of the

side panel and that the side panel is under the top flanges of the

front and rear panels. Bumps on the legs fit into holes in the side

panel to align the legs. Use four M8 x 20 carriage bolts ,

four M8 washers , four M8 lock washers , and four M8 hex

nuts to attach the side panel to the front and rear portions.

Do

not fully tighten the nuts.

4

3

2

1

D

D

1

2

3

4

5

• Repeat the prior step to attach the remaining side panel

marked to the opposite side of the stand.

1

2

3

4

D

D

6

• Attach one long bracket marked between the legs on the

right side of the stand. Make sure the legs are in front of the

brackets. Use two M8 x 20 carriage bolts , two M8 washers ,

two M8 lock washers , and two M8 hex nuts to attach the

long bracket. Do

not fully tighten the nuts. Repeat this process

to attach the remaining long bracket between the legs on the

left side of the stand.

1

2

3

4

7

F

4

3

2

1

F

8

• The front, rear and side panels have flanges that overlap to

define mounting holes through which you will bolt the saw to

the stand. There is one hole in each corner of the stand.

Adjust the panels until the holes align and then tighten all of

the nuts in the stand using a 13 mm wrench.

9

4

2

2

4

5

• Attach a foot to the bottom of

each leg by threading an M8 hex

nut on each foot and then

placing an M8 washer over

the nut. Insert a foot into the hole

at the base of each leg and then

place a second M8 washer and

thread a second M8 hex nut

onto each foot. Do

not fully

tighten the nuts. The stand is

now fully assembled.

Note: If you purchased an optional

mobile base for your saw, install it

now by following the instructions

that came with the mobile base.

4

2

2

4

5

Mounting the Saw

to the Stand

10

• Remove the saw from the box and locate the

mounting hardware. All of the hardware needed to

mount the saw to the stand is located in the area with

the yellow background on hardware pack #1.

11

• With the help of an assistant, pick up the saw and carefully set it

on the assembled stand with the front of the saw above the front

panel of the stand. Align the mounting holes in the bottom corners

of the saw with the mounting holes in the top corners of the stand.

While moving the saw do not set it down in the upright position on

a solid surface because the dust shroud can be damaged.

Warning! The saw weighs approximately 140 pounds. Be careful

and use proper lifting technique to avoid injury.

• Attach one of the short brackets marked between the two

front legs. Make sure the legs are in front of the bracket. Use

two M8 x 20 carriage bolts , two M8 washers , two M8 lock

washers , and two M8 hex nuts . Do

not fully tighten the

nuts. Repeat this process to attach

the remaining short bracket

between the rear legs.

E

1

2

3

4

1

2

4

3

E

E

mounting holes

0

15

30

45

SawStop

10”Contractor

Saw

0

15

30

45

SawStop

10”ContractorS

aw

Mounting the Saw to the Stand

Washers, M8

(32 + 2 extra)

Lock Washers, M8

(24 + 2 extra)

Assembling the Stand

Hex Nuts, M8

(32 + 2 extra)

Leveling Feet

(4)

Hardware for Steps 10-14

Hardware for Steps 1-9

Carriage Bolts, M8 x 20

(24 + 2 extra)

1

2

4

5

3

Hex Screws,

M8 x 20 (4)

6

Lock Washers,

M8 (4)

8

Hex Nuts,

M8 (4)

9

Washers,

M8 (8)

7

Hardware Pack #1

Mounting the Saw to the Stand

Washers, M8

(32 + 2 extra)

Lock Washers, M8

(24 + 2 extra)

Assembling the Stand

Hex Nuts, M8

(32 + 2 extra)

Leveling Feet

(4)

Hardware for Steps 10-14

Hardware for Steps 1-9

Carriage Bolts, M8 x 20

(24 + 2 extra)

1

2

4

5

3

Hex Screws,

M8 x 20 (4)

6

Lock Washers,

M8 (4)

8

Hex Nuts,

M8 (4)

9

Washers,

M8 (8)

7

Hardware Pack #1

F

Flip to

Other Side

© SawStop, LLC

Mounting the Saw to the Stand

Washers, M8

(32 + 2 extra)

Lock Washers, M8

(24 + 2 extra)

Assembling the Stand

Hex Nuts, M8

(32 + 2 extra)

Leveling Feet

(4)

Hardware for Steps 10-14

Hardware for Steps 1-9

Carriage Bolts, M8 x 20

(24 + 2 extra)

1

2

4

5

3

Hex Screws,

M8 x 20 (4)

6

Lock Washers,

M8 (4)

8

Hex Nuts,

M8 (4)

9

Washers,

M8 (8)

7

Hardware Pack

#

1

Tools

Hex Key, M3

(1)

Hex Key, M5

(1)

Hex Key, M8

(1)

Mounting the Switch Box

Hardware for Step 22

Switch Box Keys

(2)

Washers,

M6 (2)

14

Hex Screws,

M6 x 20 (2) 15

Installing the Motor and Belt Guard

Hardware for Steps 17-19

Washers, M5 (4)

10

Hex Nuts, M5 (4) 11

Mounting the Extension Wings

Hardware for Steps 20-21

Lock Washers,

M8 (8)

12

Hex Screws,

M8 x 16 (8) 13

Hardware Pack

#

2

Blade Spacing

Adjustment

Gauge

(1)