Making adjustments to your saw – SawStop CNS175-AU User Manual

Page 74

72 SawStop 10” Contractor Saw

Making Adjustments to Your Saw

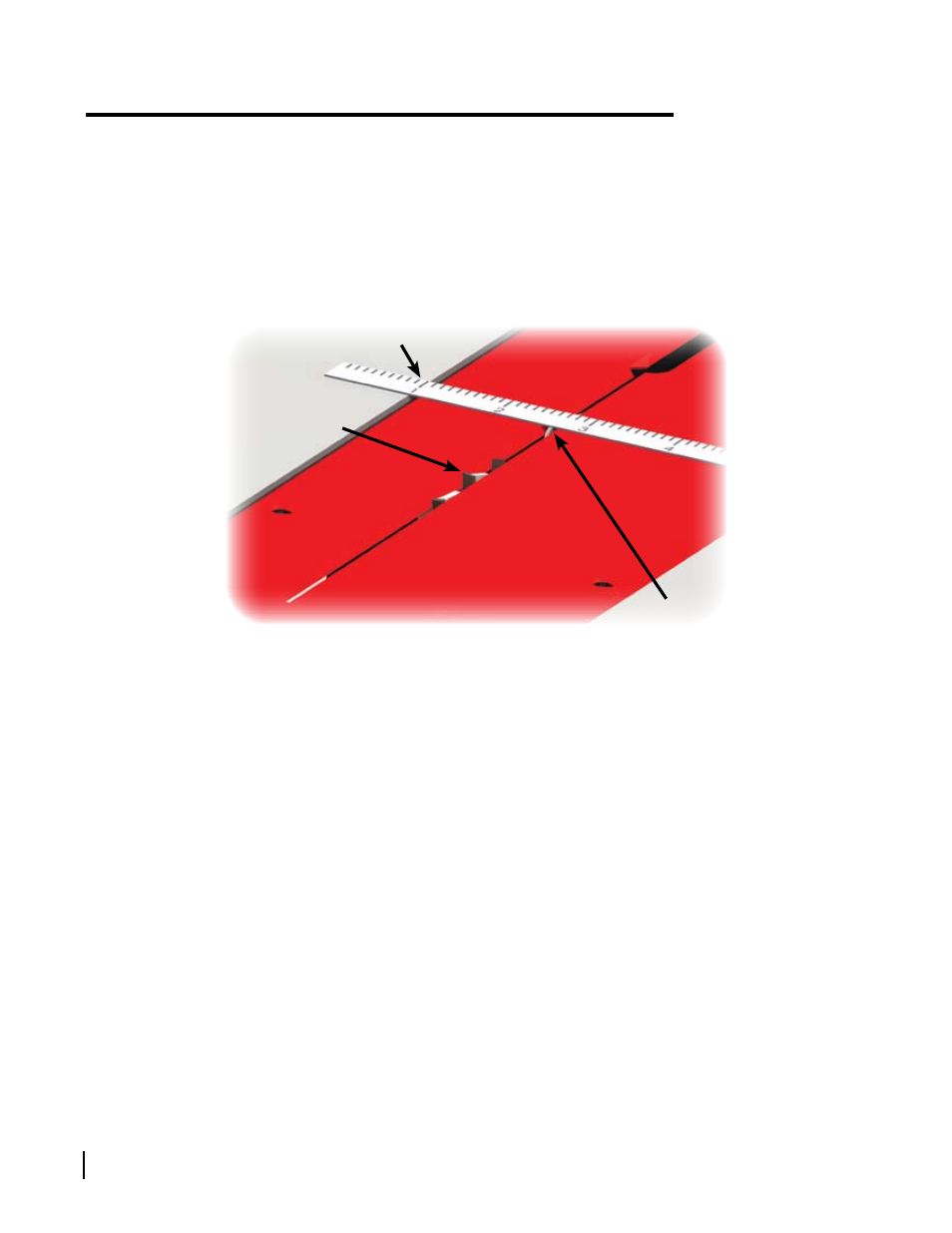

To check the height of the riving knife relative to the blade, lower the blade elevation until the lower limit stop

is engaged. Place a ruler or another straight edge on the table insert directly above the tip of the riving knife.

Raise the blade elevation until the tip of the riving knife just comes in contact with the straight edge or ruler

(see Fig. 98).

Now measure the distance from the top of the table insert to the top of the blade. If the height of the riving

knife is set correctly, the saw blade should be approximately 1 mm above the table insert. If the distance is

approximately 1 mm, no further clamp adjustments are necessary.

If the height of the riving knife is not correct, use the elevation handwheel to set the top of the blade to 1 mm

above the top of the table insert. Next, remove the table insert and loosen the two vertical positioning bolts

shown in Fig. 95 using the included 5 mm hex key. Loosen the bolts just enough so that you can slide the clamp

up and down on the clamp mounting bracket.

Next, adjust the position of the clamp up or down to set the height of the riving knife. You can also rotate the

clamp forward or backward so that the arc on the front edge of the riving knife is concentric with the blade.

When the riving knife is correctly positioned, tighten the two vertical positioning bolts just enough to hold the

clamp in position and reinstall the table insert. Check to make sure the tip of the riving knife is level with the

insert. Repeat the adjustment if necessary. Once the vertical alignment of the riving knife is correct, fully tighten

the two vertical positioning bolts.

In some cases, adjusting the vertical alignment may cause the spacing between the front edge of the riving

knife and the teeth of the blade to be incorrect. If this happens, repeat the steps explained above to adjust the

gap between the front edge of the spreader and the teeth of the blade so that it is 4-7 mm.

Once the clamp has been properly positioned, further adjustment should not be necessary. Both the spreader

and riving knife will now automatically align when installed in the clamp.

Fig. 98

tip of the

riving knife

blade tooth should

be 1 mm above

table insert

straight edge