Post-assembly checks – Goulds Pumps 3610 - IOM User Manual

Page 86

Maintenance

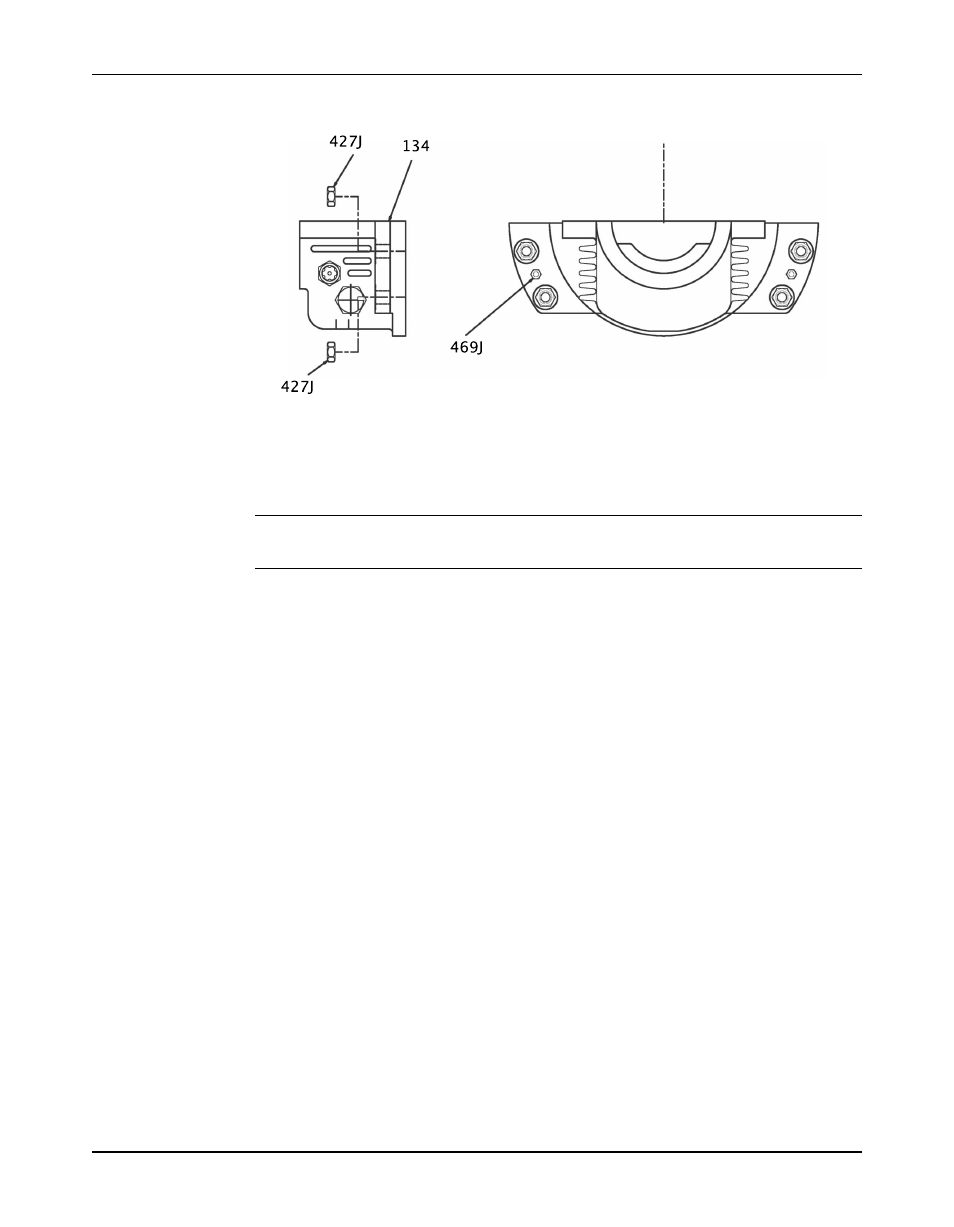

b) Install the dowel pins (469J) in the pre-drilled dowel pin holes between the housing

flange and the case bearing flange.

c) Tighten the nuts (427J) on the bearing housing to the case studs (371T).

d) Place the upper half of the sleeve bearing (117) on the shaft, moving the oil rings aside.

When the bearing top half is in place, move the oil rings back into the bearing housing

and sleeve grooves.

8. Install the outboard labyrinth seal (332A).

NOTICE:

Make sure that the expulsion port is at the 6 o'clock position and is properly seated.

9. Install the upper half of the bearing housing (134).

10. Position the dowel pins between the upper and lower halves of the bearing housing.

Tighten the bearing-housing hex screws.

Assembly of the sleeve/Kingsbury bearing arrangement

If your pump is equipped with the rarely-supplied sleeve/Kingsbury bearing arrangement, refer

to the topics Assemble the radial end (sleeve/ball bearing pumps) and Assemble the thrust end

(sleeve/ball bearing pumps) for sleeve bearing reassembly.

Also see the instructions provided by Kingsbury for specific information regarding this tilting-

pad hydrodynamic bearing.

Post-assembly checks

Perform these checks after you assemble the pump, then continue with pump startup:

• Rotate the shaft by hand in order to make sure that it rotates easily and smoothly and that

there is no rubbing.

• Open the isolation valves and check the pump for leaks.

84

Installation, Operation, and Maintenance Manual