Suction-piping checklist – Goulds Pumps 3610 - IOM User Manual

Page 29

Installation

CAUTION:

Flange loads from the piping system, including those from the thermal expansion of the piping, must not

exceed the limits of the pump. Casing deformation can result in contact with rotating parts, which can

result in excess heat generation, sparks, and premature failure.

Piping guidelines

Guidelines for piping are given in the Hydraulic Institute Standards available from the Hydraulic

Institute at 9 Sylvan Way, Parsippany, NJ 07054-3802. You must review this document before

you install the pump.

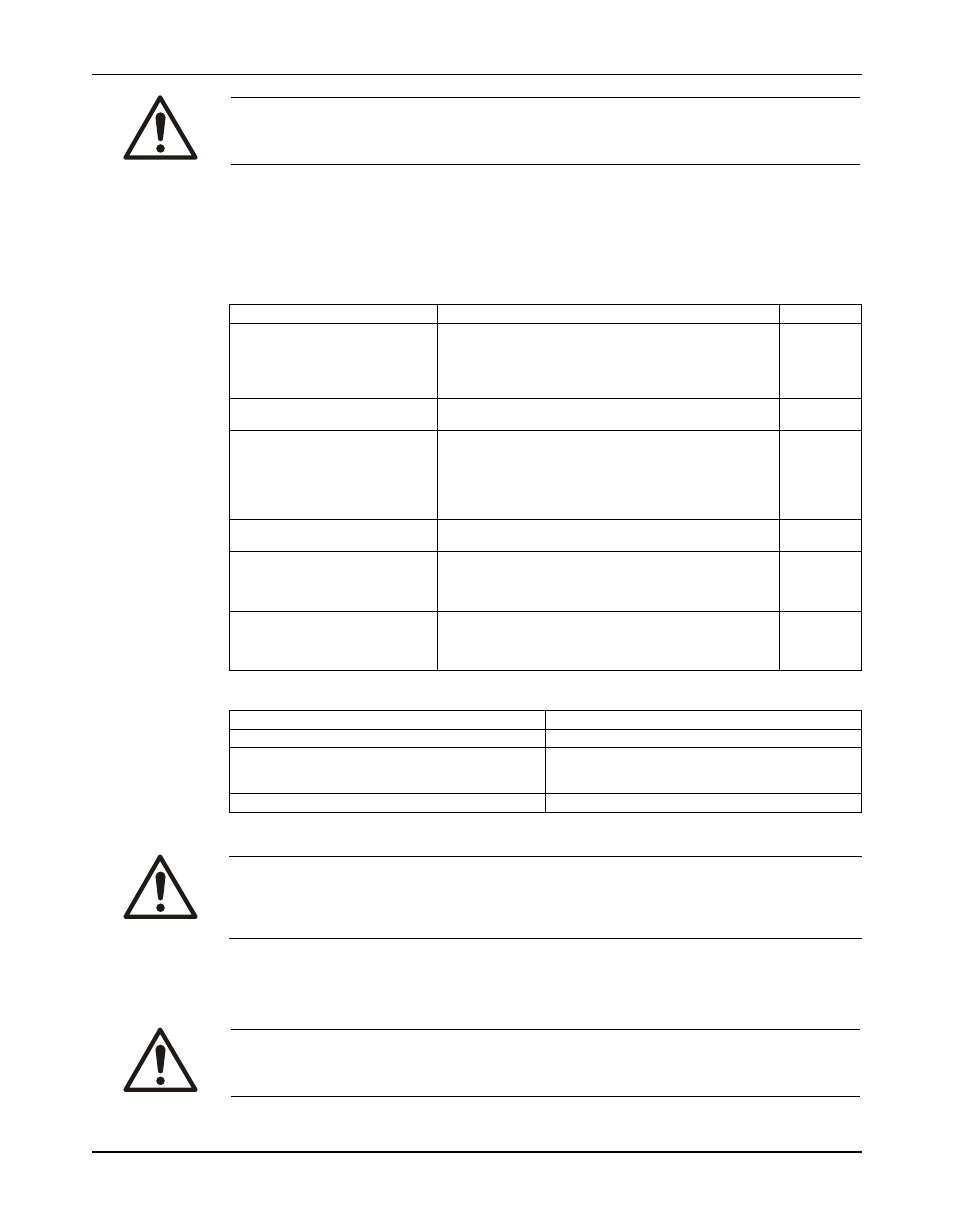

Checklist

Check

Explanation/comment

Checked

Check that all piping is supported This helps to prevent:

independently of, and lined up

• Strain on the pump

naturally with, the pump flange.

• Misalignment between the pump and the drive unit

See Alignment criteria for pump

• Wear on the pump bearings, seal, and shafting

flanges.

Check that only necessary fittings This helps to minimize friction losses.

are used.

Do not connect the piping to the

—

pump until:

• The grout for the baseplate or

sub-base becomes hard.

• The hold-down bolts for the

pump are tightened.

Make sure that all the piping joints This prevents air from entering the piping system or

and fittings are airtight.

leaks that occur during operation.

If the pump handles corrosive

fluids, make sure that the piping

allows you to flush out the liquid

before you remove the pump.

If the pump handles liquids at

elevated temperatures, make

sure that the expansion loops and

joints are properly installed.

Alignment criteria for pump flanges

Type

Criteria

Axial

The flange gasket thickness is ±0.03 in. (0.8 mm).

Parallel

Align the flange to be within 0.001 in./in. to 0.03 in./

in. (0.025 mm/mm to 0.8 mm/mm) of the flange

diameter.

Concentric

You can easily install the flange bolts by hand.

Fastening

WARNING:

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing fasteners.

Suction-piping checklist

Performance curve reference

CAUTION:

Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the suction

side. This action can result in decreased performance, unexpected heat generation, and equipment

damage.

Installation, Operation, and Maintenance Manual

27