Goulds Pumps 3610 - IOM User Manual

Page 30

Installation

Net positive suction head available (NPSH

A

) must always exceed NPSH required (NPSH

R

) as

shown on the published performance curve of the pump.

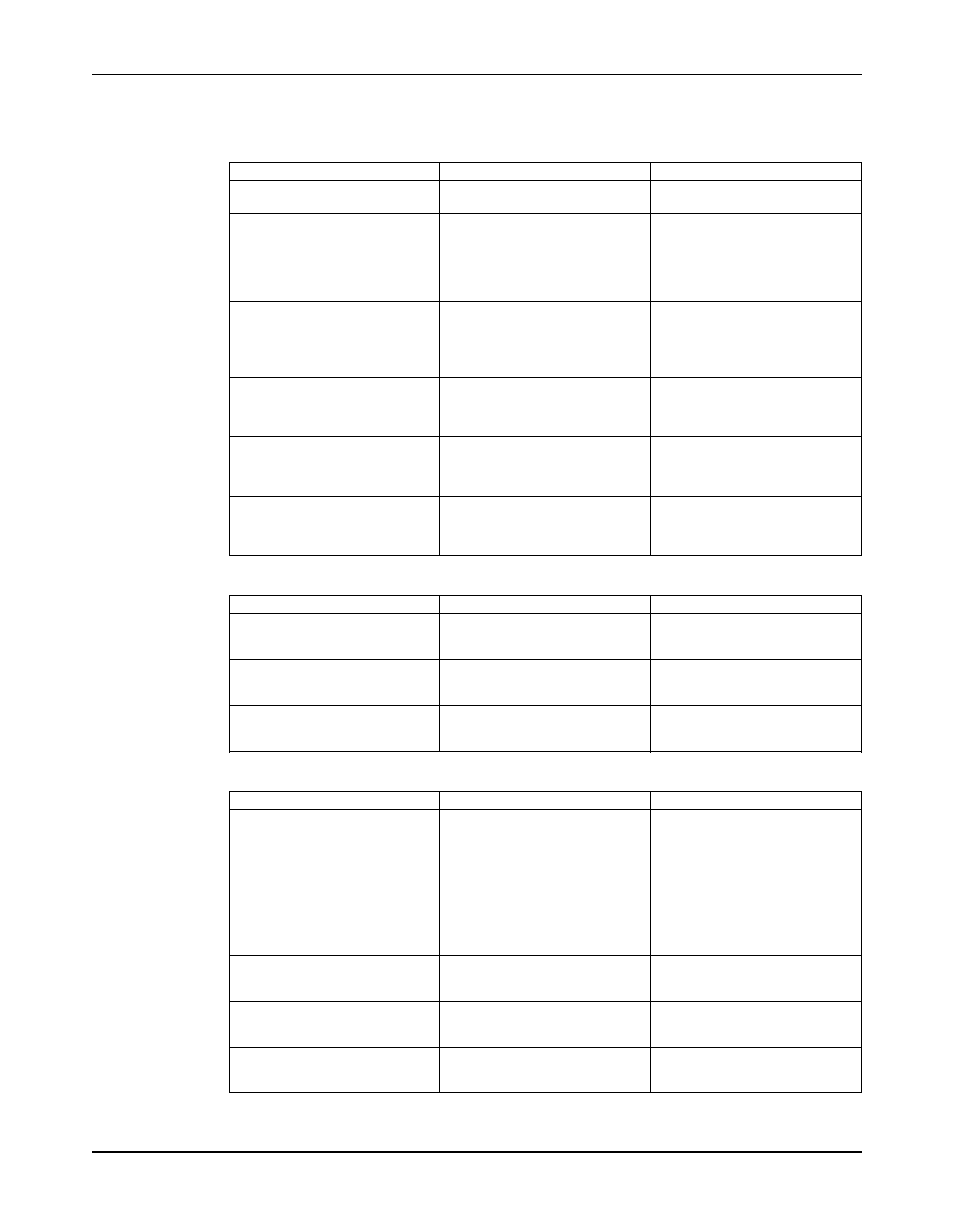

Suction-piping checks

Check

Explanation/comment

Checked

Check that elbows in general do

not have sharp bends.

Check that the suction piping is

The suction piping must never

one or two sizes larger than the

have a smaller diameter than the

suction inlet of the pump.

suction inlet of the pump.

Install an eccentric reducer be-

tween the pump inlet and the

suction piping.

Check that the eccentric reducer

at the suction flange of the pump

has the following properties:

• Sloping side down

• Horizontal side at the top

When suction strainers or suction Suction strainers help to prevent

bells are used, check that they are clogging.

at least three times the area of the

suction piping.

If more than one pump operates

This recommendation helps you to

from the same liquid source,

achieve a higher pump perfor-

check that separate suction-piping mance.

lines are used for each pump.

If necessary, make sure that the

—

suction piping includes a drain

valve and that it is correctly in-

stalled.

Liquid source below the pump

Check

Explanation/comment

Checked

Make sure that the suction piping

This helps to prevent the occur-

is free from air pockets.

rence of air and cavitation in the

pump inlet.

Check that the suction piping

—

slopes upwards from the liquid

source to the pump inlet.

If the pump is not self-priming,

Use a foot valve with a diameter

check that a device for priming the that is at least equivalent to the

pump is installed.

diameter of the suction piping.

Liquid source above the pump

Check

Explanation/comment

Checked

Check that an isolation valve is

This permits you to close the line

installed in the suction piping at a

during pump inspection and main-

distance of at least two times the

tenance.

pipe diameter from the suction

Do not use the isolation valve to

inlet.

throttle the pump. Throttling can

cause these problems:

• Loss of priming

• Excessive temperatures

• Damage to the pump

• Voiding the warranty

Make sure that the suction piping

This helps to prevent the occur-

is free from air pockets.

rence of air and cavitation in the

pump inlet.

Check that the piping is level or

—

slopes downward from the liquid

source.

Make sure that no part of the

—

suction piping extends below the

suction flange of the pump.

28

Installation, Operation, and Maintenance Manual