Piping checklists, General piping checklist – Goulds Pumps 3610 - IOM User Manual

Page 28

Installation

5. Allow the grout to set.

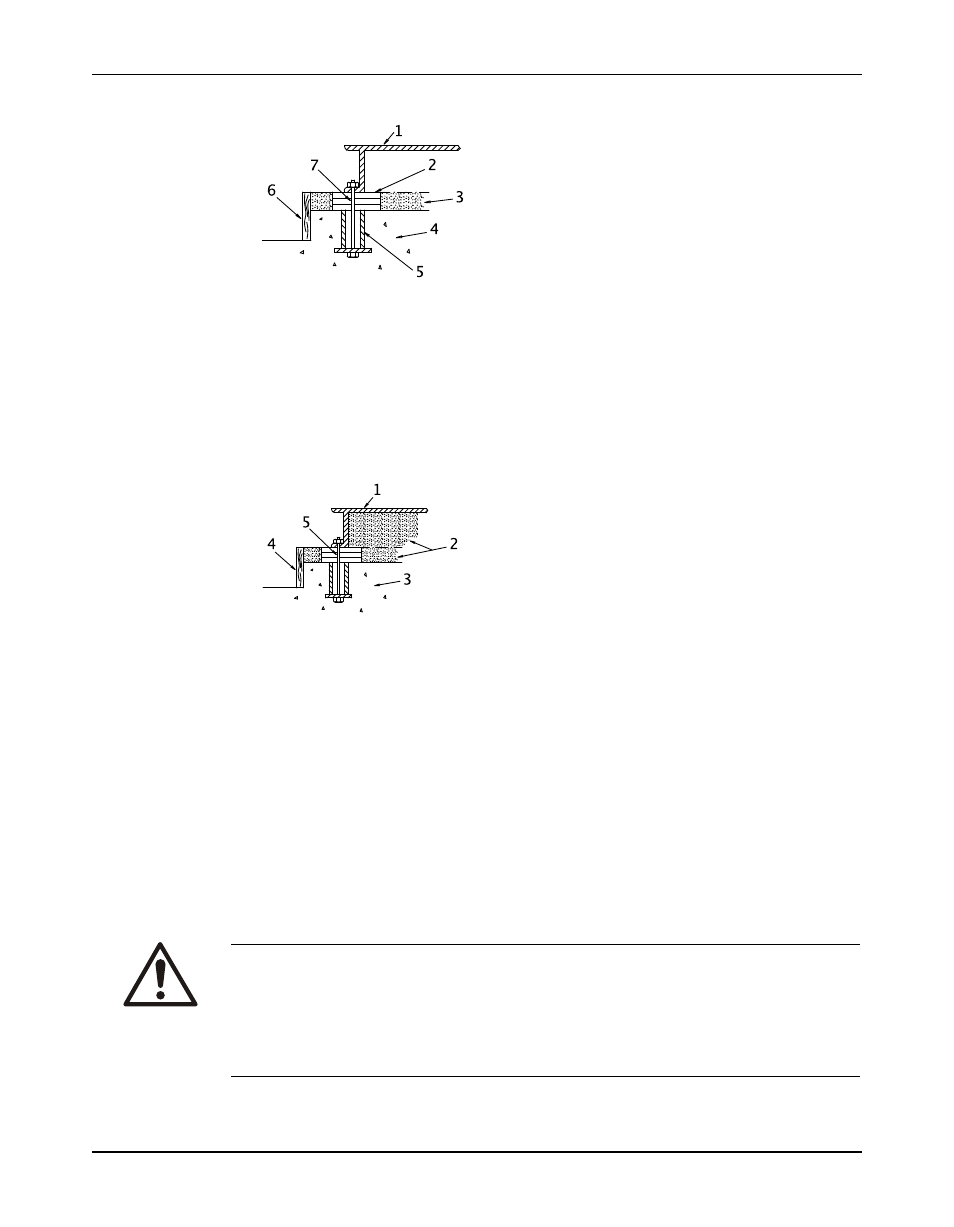

1. Baseplate

2. Shims or wedges

3. Grout

4. Foundation

5. Sleeve

6. Dam

7. Bolt

6. Fill the remainder of the baseplate with grout, and allow the grout to set for at least 48

hours.

1. Baseplate

2. Grout

3. Foundation

4. Dam

5. Bolt

7. Remove the leveling jackscrews after the grout hardens in order to remove any stress

points.

8. Tighten the foundation bolts.

9. Recheck the alignment.

Piping checklists

General piping checklist

Precautions

CAUTION:

• Never draw piping into place by using force at the flanged connections of the pump. This can

impose dangerous strains on the unit and cause misalignment between the pump and driver. Pipe

strain adversely affects the operation of the pump, which results in physical injury and damage to

the equipment.

• Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the

suction side. This action can result in decreased performance, unexpected heat generation, and

equipment damage.

26

Installation, Operation, and Maintenance Manual