Bearing lubrication, Oil volumes – Goulds Pumps 3610 - IOM User Manual

Page 40

Commissioning, Startup, Operation, and Shutdown

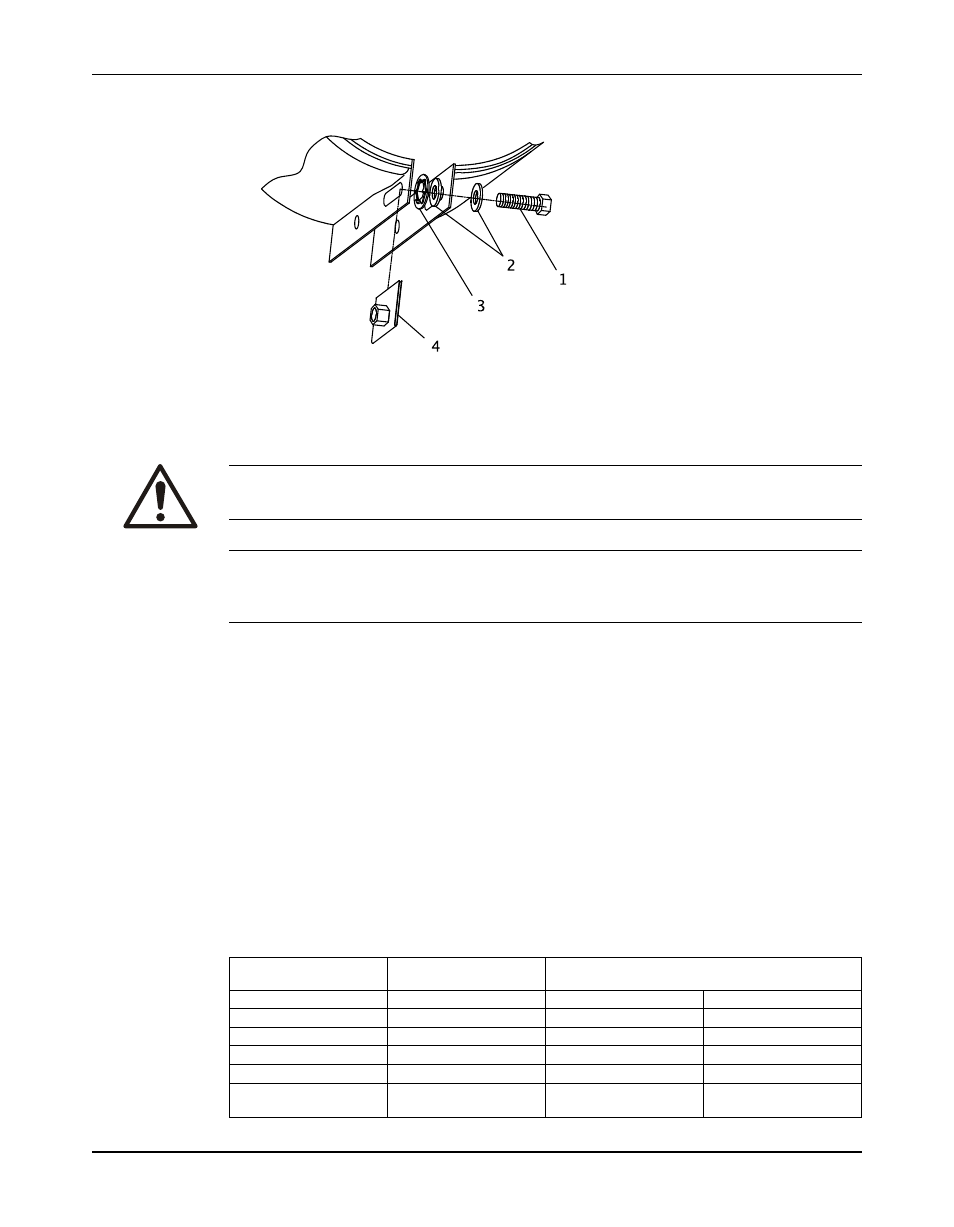

12. Place one washer over the bolt and insert the bolt through the round hole where the push

nut and clip-on nut are located. Be sure to tighten the bolt firmly.

Bearing lubrication

Precautions

WARNING:

Make sure to properly lubricate the bearings. Failure to do so can result in excess heat generation,

sparks, and premature failure.

NOTICE:

Avoid equipment damage. Refer to driver/coupling/gear manufactures IOM for instructions and

recommendations for lubrication.

Pumps are shipped without oil

You must lubricate oil-lubricated bearings at the job site.

Ring oil lubrication

Ring oil-lubricated bearings are standard. Bearing housings are supplied with constant-level

oilers and sight glasses. Make sure that oil rings are properly seated in the grooves in the shaft.

Pure or purge oil-mist lubrication

Pure or purge oil mist are optional features. Follow the oil-mist generator manufacturer's

instructions. The inlet and outlet connections are located on the top and bottom of the bearing

housing, respectively.

Oil volumes

Oil volume requirements for ball/ball and sleeve/ball bearings

This table shows the required amount of oil for oil-lubricated bearings.

All frames in this table use a Watchdog Oiler, which has a capacity of 4 oz. (118 ml).

Size

Nameplate radial

Bearing housing oil volume

bearing

ounces

milliliters

S

6309

22

651

M/MX

6312

35

1035

L/LX

6313

58

1715

XL

6318

72

2129

X, XX, XXL, XLX

6320

89

2632

6224

38

Installation, Operation, and Maintenance Manual