Assemble the radial end (ball bearing pumps) – Goulds Pumps 3610 - IOM User Manual

Page 80

Maintenance

NOTICE:

The bearing housing flange must fit metal-to-metal (no gap) to the bearing saddle flange.

5. Install the bearing end cover (160) with the end-cover capscrews (371C).

6. Install the oil ring (114).

7. Install the bearing end cover (109A) and the bearing end-cover gasket (360A) with the

outboard end-cover capscrews (371C).

8. When new bearings are installed, you must measure the axial end play:

a) Bolt the end cover to the thrust housing.

b) Move the shaft axially from the coupling end.

c) Measure the shaft axial movement with a dial indicator mounted on the radial bearing

housing.

This table shows the clearance requirements between the thrust bearing end cover and the

bearing:

Bearing type

Clearance in inches (millimeters)

Ball/ball

0.005-0.010 (0.127-0.254)

Sleeve/ball

0.005-0.010 (0.127-0.254)

Sleeve/Kingsbury

0.010–0.013 (0.254–0.330)

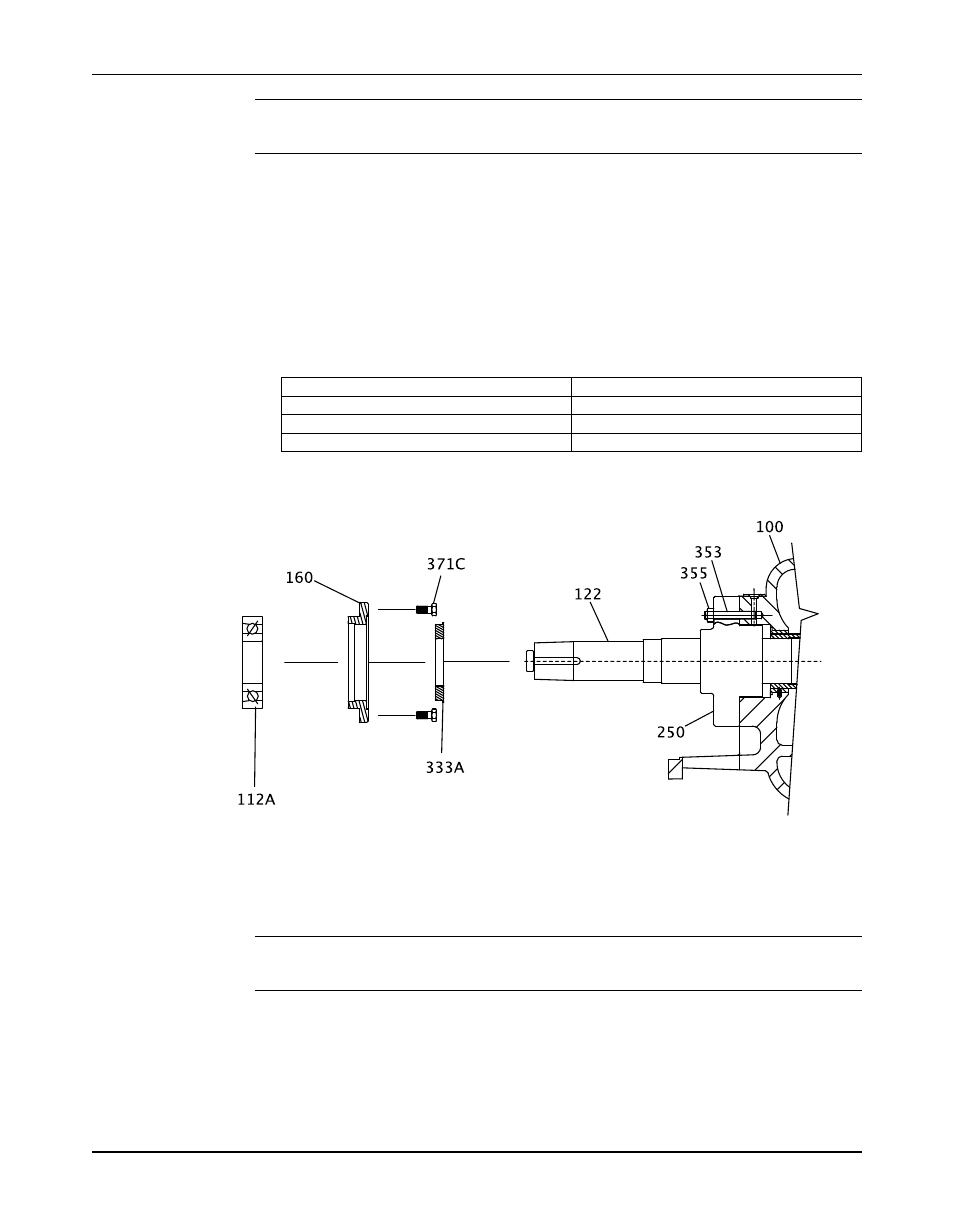

Assemble the radial end (ball bearing pumps)

1. Assemble the inboard labyrinth seal (333A) into the inboard radial-end cover (160):

a) Clean the end cover with a solvent.

b) Fit the labyrinth seal (333A) into the bore of the cover (160).

c) Tap the seal in with a hammer.

NOTICE:

Make sure that the expulsion port is at the 6 o'clock position and is properly seated.

2. Assemble the inboard end cover (160) and the inboard bearing end-cover gasket (360A)

onto the shaft.

3. Assemble the radial bearing (168) onto the shaft (122).

The bearings are interference fit.

78

Installation, Operation, and Maintenance Manual