Goulds Pumps 3610 - IOM User Manual

Page 81

Maintenance

a) Preheat the bearings with an electronic induction heater.

The induction heater also demagnetizes the bearings.

CAUTION:

Wear insulated gloves when you use a bearing heater. Bearings get hot and can cause physical injury.

NOTICE:

Do not use a torch and do not force.

b) Coat the internal surface of the bearings with the lubricant that is to be used in service.

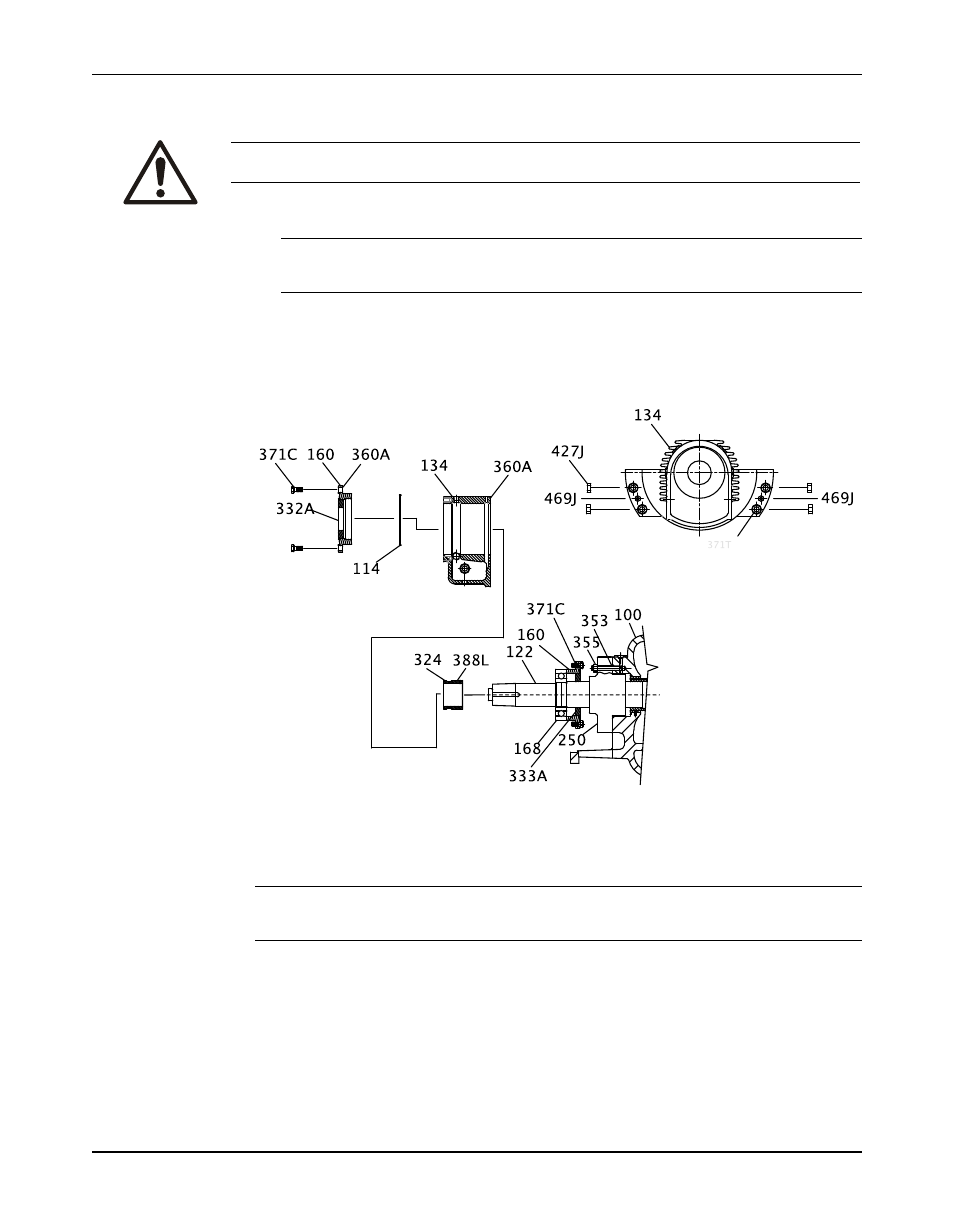

c) Assemble the radial-end bearing (168) onto the shaft (122).

S-group pumps have a bearing spacer (217).

4. Install the oil-ring sleeve (324) and tighten the setscrew (388L).

5. Install the bearing housing (134).

The bearing housing is doweled to the casing (100) during the original build to assure the

correct running position of the shaft.

NOTICE:

The bearing housing flange must fit metal-to-metal (no gap) to the bearing saddle flange.

6. Install the oil ring (114).

7. Install the end-cover gasket on the outboard side (360A).

8. Assemble the outboard labyrinth seal (332A) into the outboard radial-end cover (160):

a) Clean the end cover with a solvent.

b) Fit the labyrinth seal (332A) into the bore of the cover (160).

c) Tap the seal in with a hammer.

Installation, Operation, and Maintenance Manual

79