Pr n, Atvn, Xyst – NOVUS Controller N2000S User Manual

Page 5: Sert, Serr, Serf, Sp.a1, Tbas, Ptol, Psp0

Controller N2000S

NOVUS AUTOMATION

5/9

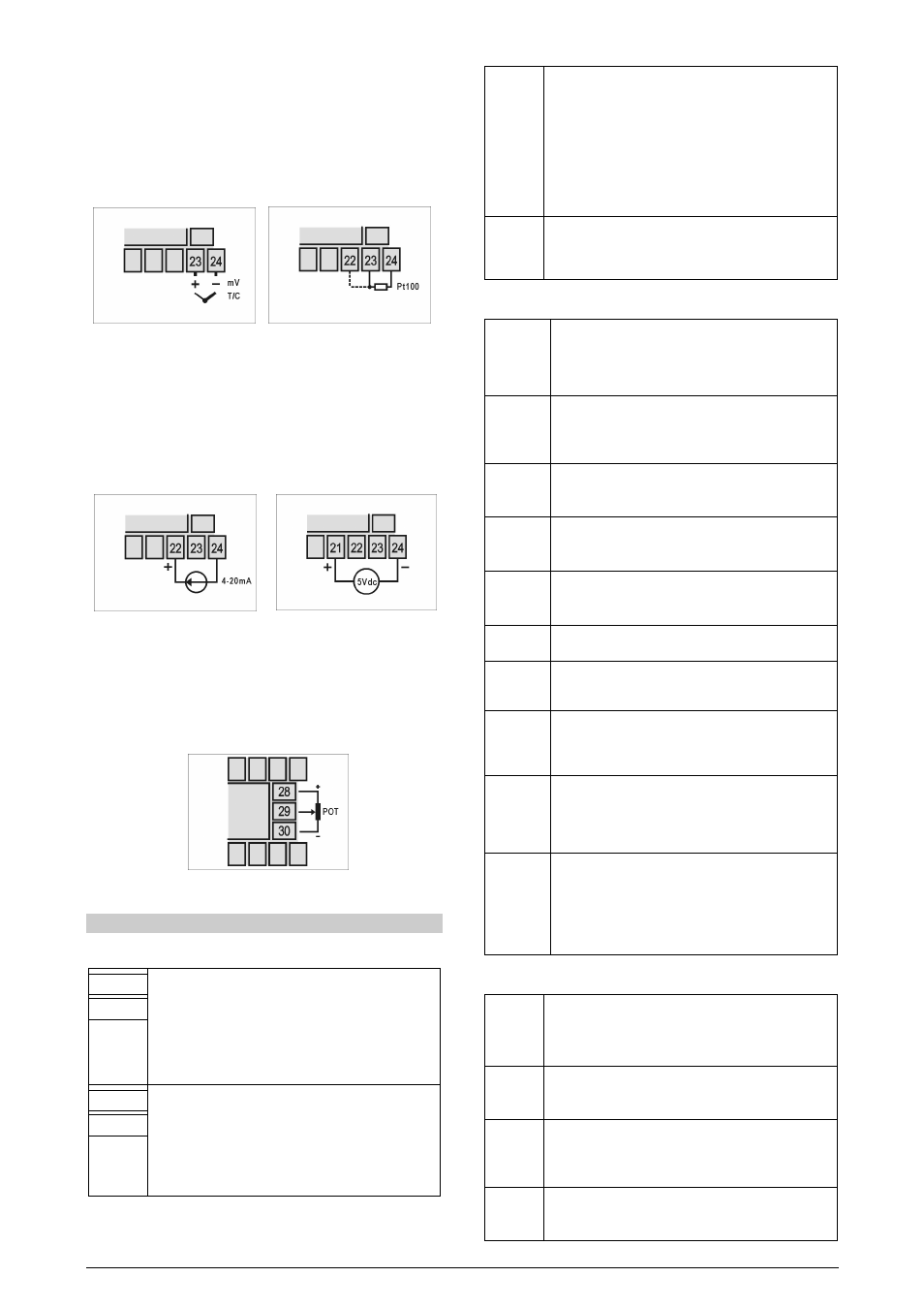

INPUT CONNECTIONS

It is important that they are very well connected; the sensor wires

must be well fixed in the terminals of the rear panel.

•

Thermocouple (T/C) and 50 mV:

Figure 3 shows how connections are made. If extension of the

thermocouple is required, proper compensation cables should be

provided.

Figure 3 – Thermocouple and 0-50

mV

Figure 4 - Pt100 wiring with three

conductors

•

RTD (Pt100):

Figure 4 shows the Pt100 wiring for 3 conductors. Terminals 22, 23,

and 24 must have the same wire resistance for proper cable length

compensation (use conductors with the same gauge and length). In

case the sensor has 4 wires, one should be left loose near the

controller. For 2-wire Pt100, short circuit terminals 22 and 23.

Figure 5 – Connection of 4-20 mA

Figure 6 – Connection of 5 Vdc

•

4-20 mA: Figure 5 shows the 4-20 mA current signals wiring.

•

0-5 Vdc: Figure 6 shows the 0-5 Vdc voltage signals wiring.

•

Alarm and output connection

When I/O channels are set up as output channels, they must have

their capacity respected, according do specifications.

Figure 7 – Potentiometer connection

CONFIGURATION PARAMETERS

OPERATION CYCLE

PV Indication

(Red)

SV Indication

(Green)

PV and SP indication: The upper status display shows the

current value of PV. The lower parameter display shows SP

value of automatic control mode.

The upper display shows “- - - -“ whenever PV exceeds the

maximum range or there is no signal at the input. In case of

hardware error the status display will show “Er

Er

Er

Er n

n

n

n”, where n

is the error code.

PV Indication

(Red)

MV Indication

(Green)

MANIPULATED VARIABLE VALUE (MV) (control output):

The upper display shows PV value and the lower display

shows the percentage of MV applied to the control output.

When in manual control, the MV value can be changed.

When in auto mode, the MV value is only for visualization.

To distinguish the MV display from the SP display, the MV

flashes intermittently.

Pr n

Pr n

Pr n

Pr n

Program

number

PROGRAM EXECUTION: Selects the ramp and soak

program to be executed.

0 – does not run program

1, 2, 3, 4, 5, 6 and respective program.

When the control is enabled, the program selected runs

immediately.

In the program cycle of ramp and soak there is a parameter

with the same name. In that context, the parameter is

associated with the number of the program that will run.

rvn

rvn

rvn

rvn

ENABLES CONTROL AND ALARMS OUTPUT:

YES - control and alarm enabled;

NO - control and alarms enabled.

TUNING CYCLE

atvn

atvn

atvn

atvn

(Auto-tune) – auto tune of PID parameters. See item 9 in this

manual.

YES – Enables auto tune.

NO – Disables auto tune.

Pb

Pb

Pb

Pb

(Proportional band) – PROPORTIONAL BAND: P term

value of the PID control, percentage of maximum input type

span. Adjustable between 0 and 500 % If adjusted to

zero, control is ON/OFF.

xyst

xyst

xyst

xyst

(HYSteresis) – CONTROL HYSTERESIS: Hysteresis value

for ON/OFF control. This parameter is shown only for

ON/OFF control (Pb=0).

Ir‘

Ir‘

Ir‘

Ir‘

(integral rate) – INTEGRAL RATE: Value of I term of PID

control in repetetions per minute (Reset). Adjustable

between 0 and 24.00. Presented if proportional band

≠

0.

dt

dt

dt

dt

(derivative time) - DERIVATIVE TIME: Value of D term of

the PID control in seconds. Adjustable between 0 and 250

s. Presented if proportional band

≠

0.

sert

sert

sert

sert

(Servo time) – time of servo excursion, from totally open to

totally closed. Programmable from 15 to 600 s.

serr

serr

serr

serr

(Servo resolution) – control resolution, determines the dead

band of servo activation. Very low values (<1 %) make the

servo “nervous”

serF

serF

serF

serF

(Servo filter) – PID output filter, before use by the servo

control. It is the time the PID mean is made, in seconds.

The output is only activated after this time. Recommended

value: > 2 s.

act

act

act

act

(Action) – CONTROL ACTION: Only in the automatic control

mode

Reverse action (“ rE

rE

rE

rE “) usually used for heating;

Direct action (“ rE “) usually used for cooling

Sp.a1

Sp.a1

Sp.a1

Sp.a1

Sp.a2

Sp.a2

Sp.a2

Sp.a2

(SetPoint of Alarm) – ALARM SP: Value that defines the

trigger point of alarms programmed with the “Lo” or “Hi”

functions. In alarms programmed with the function

Differential this parameter defines the deviation. See item

5.3.

It is not used in other alarm functions.

PROGRAM CYCLE

tbas

tbas

tbas

tbas

TIME BASE: Selects the time base for the ramp and soak.

Valid for all profile programs.

0

0

0

0

- PT1 to PT7 values are in seconds;

1

1

1

1 - PT1 to PT7 values are in minutes;

Pr n

Pr n

Pr n

Pr n

(Program number) – PROGRAM EDITING: Selects the ramp

and soak program to be edited in the next prompts of this

cycle.

Ptol

Ptol

Ptol

Ptol

(Program tolerance) – PROGRAM TOLERANCE: Maximum

deviation between PV and SP. Whenever this deviation is

exceeded the time counter is halted until deviation lowers to

acceptable values. Set zero to disable this function.

Psp0

Psp0

Psp0

Psp0

Psp7

Psp7

Psp7

Psp7

(Program SetPoint) – PROGRAM SPs, 0 TO 7: Set of 8 SP

values that define the ramp and soak program profile (see

item 8).