Installation / connections – NOVUS Controller N2000S User Manual

Page 4

Controller N2000S

NOVUS AUTOMATION

4/9

•

Minimum differential

It is activated when the measured value is below the value defined in.

(SP - Deviation)

•

Maximum differential

It is activated when the measured value is above the value defined in:

(SP + Deviation)

ALARM TIMER

Alarms can be programmed to have timer functions. The user can

delay alarm activation, set one pulse per activation, or make the

alarm signals operate in sequential pulses. Alarm timer is available

only for alarms 1 and 2 when “A1t1

A1t1

A1t1

A1t1”, “A1t2

A1t2

A1t2

A1t2”, “A2t1

A2t1

A2t1

A2t1” and “A2t2

A2t2

A2t2

A2t2

parameters are programmed.

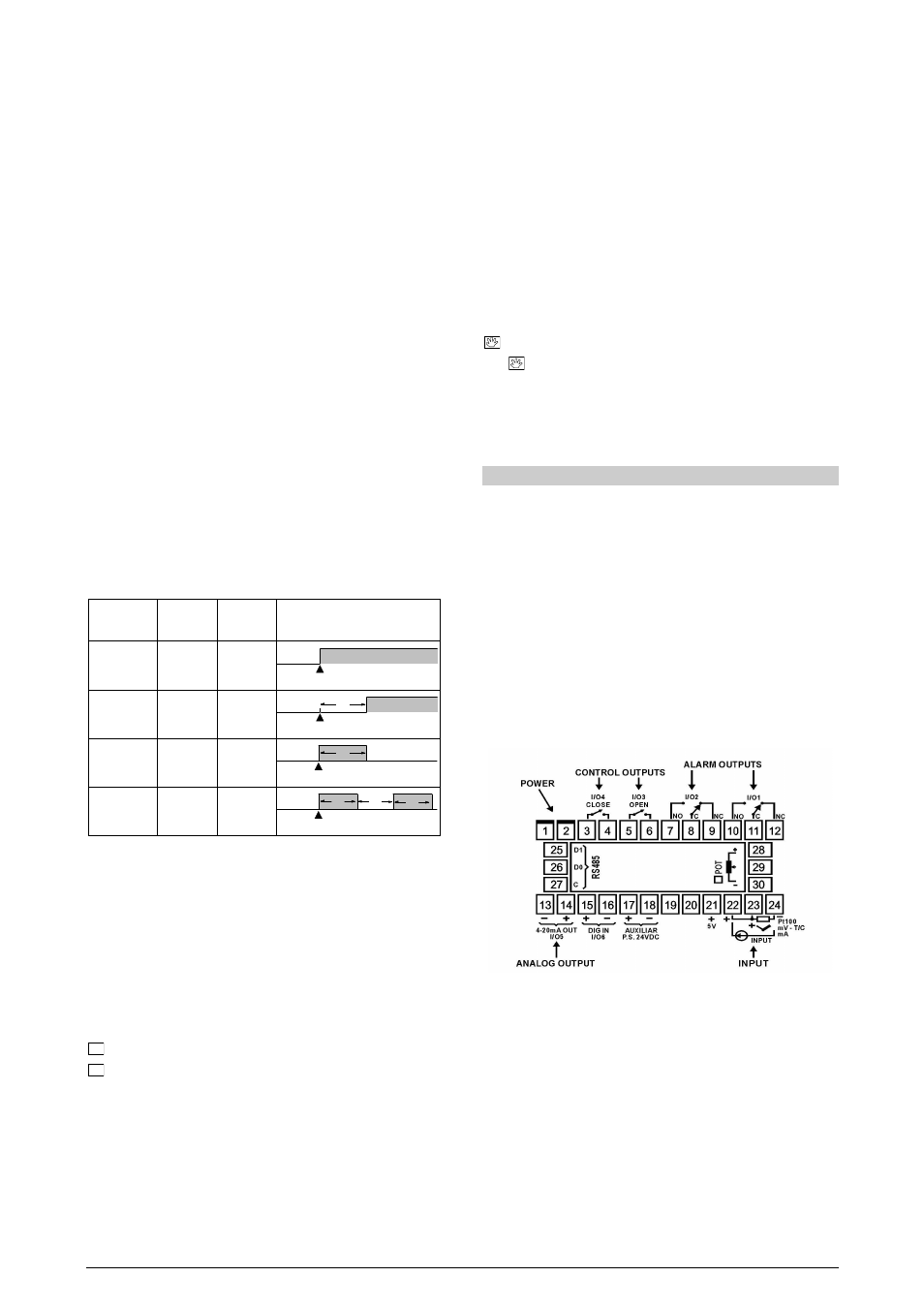

Figures shown in Table 4 represent these functions, t 1 and t 2 may

vary from 0 to 6500 seconds and their combinations define the timer

mode. For normal operation, with no alarm timer activation, t 1 and t 2

must be assigned 0 (zero).

The LEDs associated to the alarms will flash whenever an alarm

condition is acknowledged, regardless the actual state of the output

relay, which may be temporarily off because of temporization.

ALARM INITIAL BLOCKING

The initial blocking option prevents the alarm from being recognized if

an alarm condition is present when the controller is turned of for the

first time. The alarm could be activated only after the occurrence of a

non-alarm condition followed by a new occurrence of an alarm

condition. The initial blocking is useful, for example, when one of the

alarms is programmed as minimum value alarm, which can trigger the

alarm at the system startup. This is not always required.

The initial blocking is disabled for the open sensor function.

ALARM

FUNCTION

t1

t2

ACTION

Normal

0

0

Alarm Event

Alarm

Output

Delayed

0

1 to 6500 s

Alarm Event

Alarm

Output

T2

Pulse

1 to 6500 s

0

Alarm Event

Alarm

Output

T1

Oscillator

1 to 6500 s 1 to 6500 s

Alarm Event

Alarm

Output

alarme

T1

T2

T1

Table 4 – Temporization functions for Alarms 1 and 2

PV AND SP ANALOG RETRANSMISSION

The controller has an analog output (I/O5) that can make a 0-20 mA

or 4-20 mA retransmission proportional to the PV or SP values

assigned. The analog retransmission is scalable, this means it has

max. and min. limits that define the output range, which can be

defined in parameters “SPLL

SPLL

SPLL

SPLL” and “SPkL

SPkL

SPkL

SPkL”.

To obtain voltage retransmission the user must install a shunt resistor

(550

Ω

max.) in the analog output terminal. The resistor value

depends on the voltage range required.

F

KEY FUNCTIONS

F

key (special function key) in the frontal panel of the controller can

perform the same function as the Digital Input I/O6 (except function

6). The key function is defined by the user in the “fFvn

fFvn

fFvn

fFvn” parameter:

0

0

0

0 -

Disables the alarm;

7

7

7

7 – Defines the channel for the digital input and turns off the

(“RvN

RvN

RvN

RvN”: YES / no) control.

Closed = enabled outputs

Open = control output and alarms turned off;

8

8

8

8 – Invalid selection;

9

9

9

9 – Defines the channel that will command programs execution

Closed = enables program execution

Open = interrupts program

Note: When the program is interrupted, execution is held (the control

remains active). The program resumes when the signal applied to the

digital input allows it (closed contact).

10

10

10

10 – Defines channel to select program 1. This option is useful

when the user wants to switch between the main setpoint and

a second one defined in the program of ramp and soak.

Closed = selects program 1;

Open = takes the main setpoint

Note: When a function is selected to operate through digital

input, the controller does not respond to the equivalent function

command given in the frontal keypad.

KEY

The

key is located in the frontal panel. It performs function 6 of

the digital input I/O6: switch between automatic and manual control.

Operation of this key is enabled in parameter aven.

aven.

aven.

aven.

The MAN indicator flashes when the manual control mode is

selected.

INSTALLATION / CONNECTIONS

PANEL MOUNTING

The controller must be panel-mounted following the steps presented

below:

1.

Make the panel slot;

2.

Remove fixing brackets;

3.

Insert the controller into the panel slot;

4.

Replace the clamps in the controller pressing it to reach a

firm grip at the panel.

ELECTRICAL CONNECTIONS

It is not necessary to disconnect the rear panel terminals to remove

the internal circuit. Figure 2 shows how signals are distributed in the

controller rear panel.

Figure 2 – Rear panel terminals

INSTALLATION RECOMMENDATIONS

•

Conductors of input signals must be distant from activation or

high-tension/current conductors, preferably passing through

grounded conduits.

•

A specific electrical power supply network should be provided for

instruments use only.

•

In

controlling

and

monitoring

applications,

possible

consequences of any system failure must be considered in

advance. The internal relay alarm does not provide total

protection.

•

RC filters (for noise reduction) in inductor charges (contactors,

solenoids, etc.) are recommended.