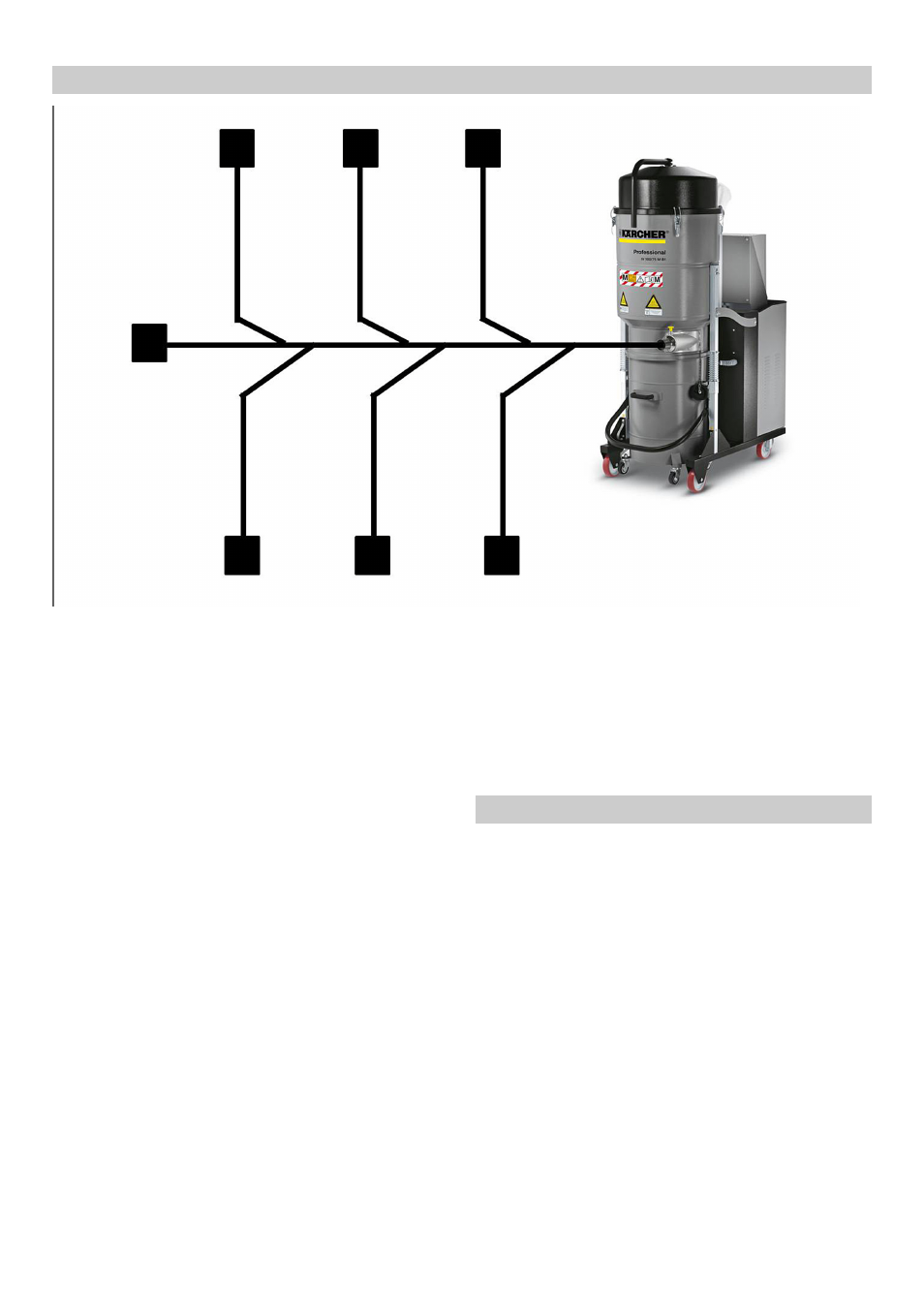

2 route planning, 3 system planning, 2 route – Karcher IV 100 - 55 M B1 User Manual

Page 8: Planning, 3 system, 2 route planning 8.3 system planning

8

English 5.906-587.0 Rev. 00 (05/14)

Note

The objective is to keep the resistance in the pipeline sys-

tem as small as possible.

–

Always choose the shortest possible way.

–

Course as straight as possible with as few cracks and

bends as possible.

–

Use of the ways of other supply runs e.g. of present

pipelines, cable runs etc.

–

No obstruction of ways or systems.

–

Provide for easily accessible cleaning opening.

–

Optimum installation height is 2-3 m.

–

Plan the junctions on the same height or with a slight in-

cline to the main line.

–

Always align Y-pieces to the side, never towards the

top or bottom (medium can drain).

–

The overall cross section of the nozzle at the machine

to be vacuumed off and its branch should not exceed

the cross sectional area of the suction stub at the vac-

uum cleaner.

–

The suction stub at one single machine must not be

larger than the total connection cross section at the

vacuum cleaner.

–

90° junctions (tees) must be avoided in general.

–

With longer branch lines the cross section of the pipe-

line should be chosen larger than the suction nozzle

connection.

–

A taper of the pipe cross section must only be designed

smaller from the vacuum cleaner to the vacuuming

points and should be as close as possible to the vacu-

uming point.

–

Every vacuuming point should be equipped with a lock-

ing slide that is always closed after the switch-off of the

machine or the end of the suction process.

–

Hoses have a high pressure loss due to their large fric-

tional resistance. Due to this circumstance, the hose

lengths must be reduced to a minimum.

–

Always use a hose sleeve at the end of the hose, and

earth the wire helix of the hose on the hose sleeve by

means of a screw in order to create a potential equali-

sation.

–

All pipelines must be connected in an electrically con-

ductive way from the machine branch to the intercept-

ing pipe.

With the 4 given framework requirements a rough planning

of the stationary system can take place.

1 Spatial conditions.

2 Number of the overall and the simultaneously working

vacuuming points.

3 Required air speed.

4 Kärcher vacuum and pipeline programme.

Part one "Design pipe system" of the calculation tool for

stationary vacuuming systems can be used for the calcu-

lation of the pipe diameter (see Chapter "Calculation tool

pipe system design").

The inner diameter is calculated respectively and the pipe

closest to the calculated diameter is chosen.

With the fixed pipeline diameter the air speed actually

achieved must be calculated again.

If it does not suffice for the material to be vacuumed, the

pipeline must be redesigned or a more powerful vacuum

cleaner must be used.

8.2

Route planning

8.3

System planning