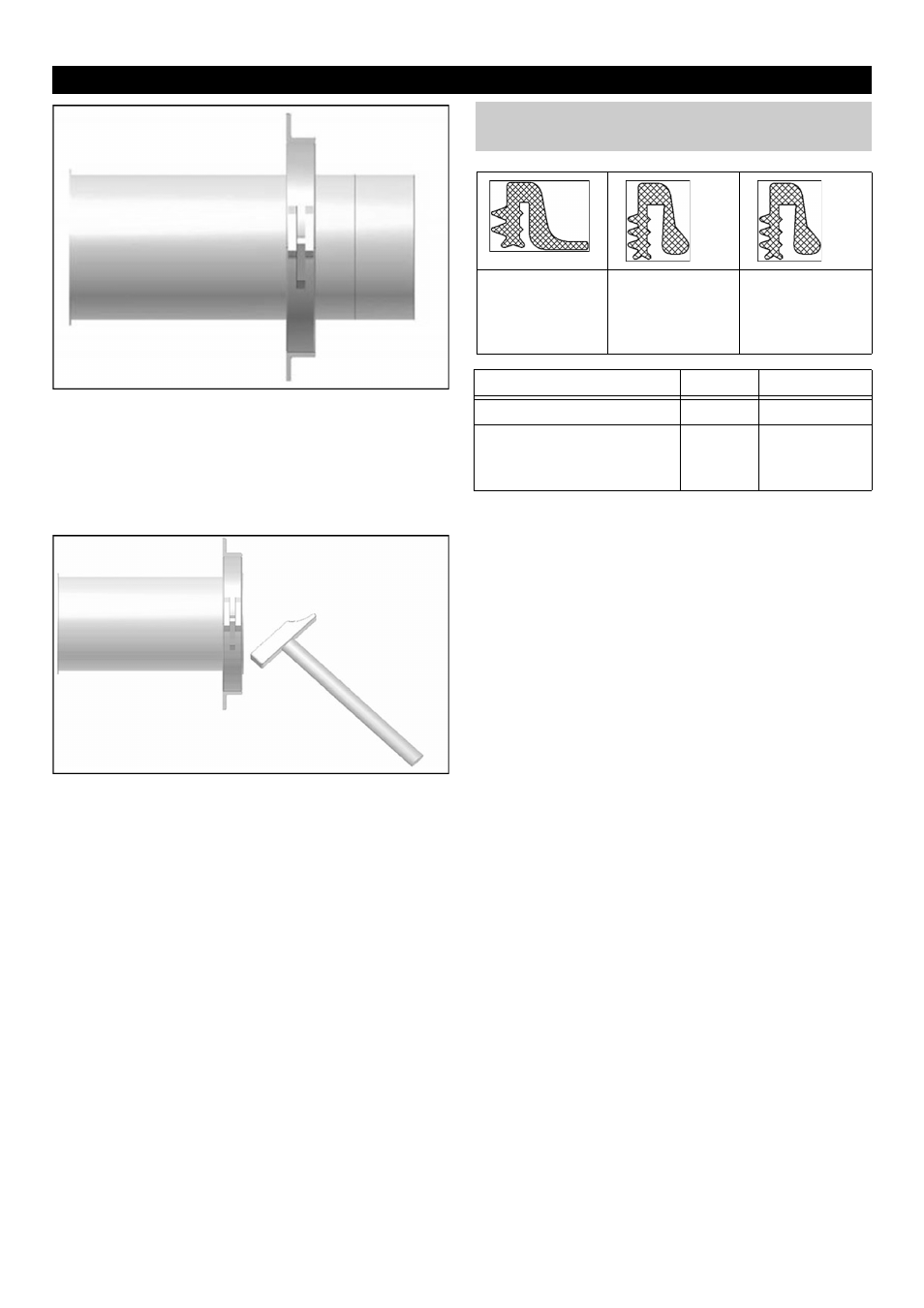

Producing a flanged edge, 1 information concerning border sealings, 15 producing a flanged edge – Karcher IV 100 - 55 M B1 User Manual

Page 28

28

English 5.906-587.0 Rev. 00 (05/14)

Measure the fitting length and transfer it to the pipe (fit-

ting length + 7 mm for the flanged edge).

Set the flanging device with the edge to this length and

mark the cutting line over the circumference of the pipe.

Push back the flanging device and cut the pipe to length

using a cutoff wheel or a saw.

Then clamp the pipe into the flanging device so that it

projects 7 mm.

Turn up the projecting hose using a hammer until an

even, sharp-edged flanged edge has been created.

For connections of:

–

2 mm and 2 mm thick pipe parts

–

2 mm and 1.5 mm thick pipe parts

–

2 mm and 1 mm thick pipe parts*

–

1.5 mm and 1.5 mm thick pipe parts*

* In case of high requirements on the tightness of the con-

nection, the thicker flanged sealing ring should be used for

1 mm pipework.

15 Producing a flanged edge

15.1 Information concerning border

sealings

Profile for 1 mm

in:

EPDM conductive

Profile for 2 mm

in:

NBR, silicone,

Viton

Profile for 2 mm

in:

EPDM conductive

Rubber quality

Colour

Temperature

NBR (nitrile rubber)

Grey

100 ?

EPDM (Keltan)

Black

(conduc-

tive)

120 ?