Karcher IV 100 - 55 M B1 User Manual

Page 27

English 5.906-587.0 Rev. 00 (05/14)

27

CAUTION

–

When closing the tension ring, the flanged sealing ring

must not form a loop. In order to facilitate the closing

process, the tensioning screw at the joint can be

screwed back if necessary.

–

Then the tensioning screw must be tightened to prevent

accidental unlocking of the joint (e.g. in case of vibra-

tions) and to increase the tightness.

–

For explosion-proof connections up to 3 bar overpres-

sure a tightening torque of 10 Nm is required.

Note

It is advisable to completely disassemble the tension ring

first. However, it can also be mounted analogously to the

QUICK CONNECT© tension ring by completely loosening

one screw only.

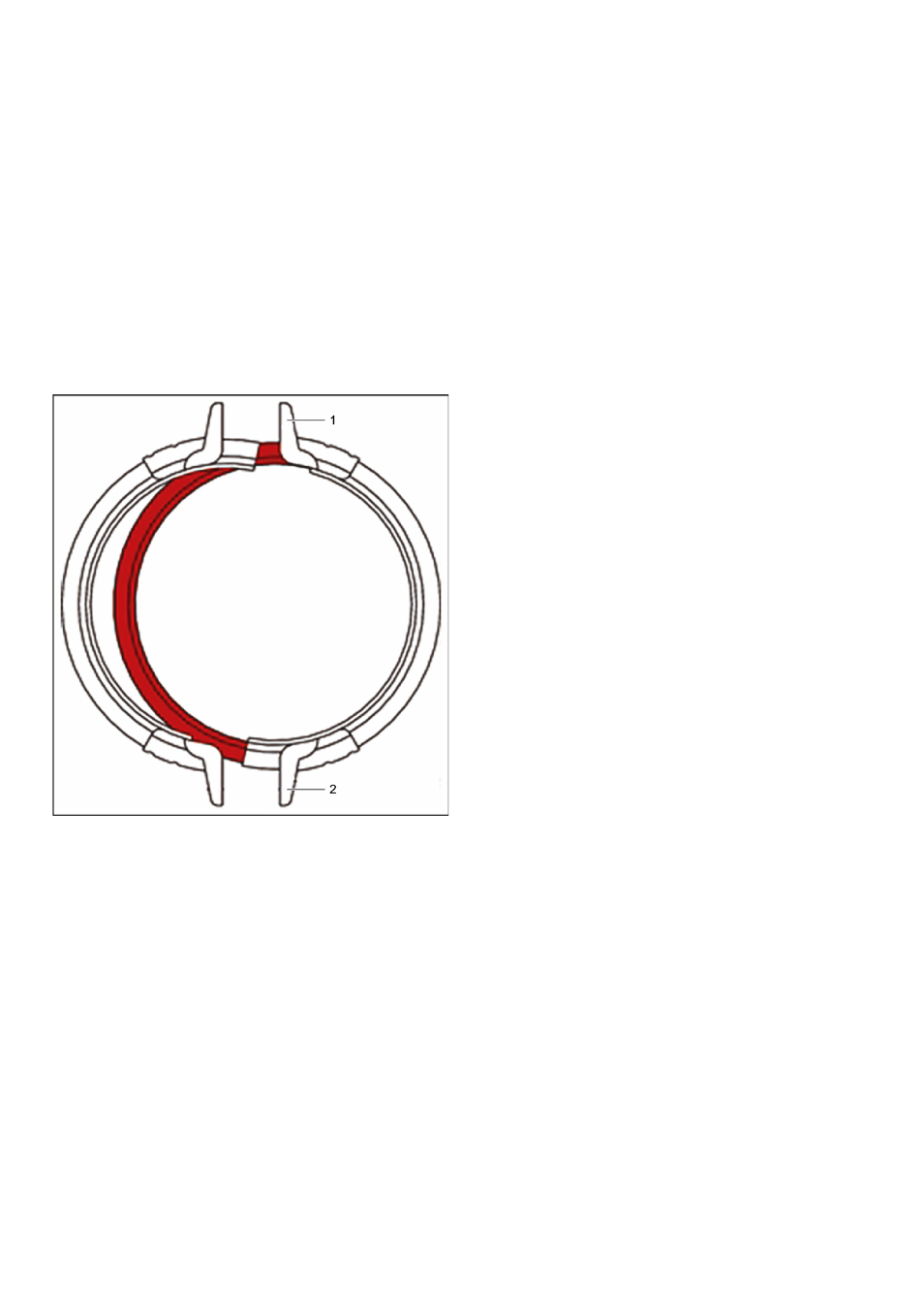

Tension ring two-part

1 Clamping shoe projecting

2 Clamping shoe recessed

Push the second tension ring half onto the flanged edg-

es.

Insert screws and evenly tighten them alternately on

each side.

CAUTION

–

The flanged sealing ring must not form any loops.

–

With explosion-proof connections up to 3 bar overpres-

sure a tightening torque of 25 Nm is required.

–

For all listed tension rings a hexagon cap screwdriver

with 6 mm width across flats is required.