Prerequisite system planning, Basics of the system planning, 1 air speed – Karcher IV 100 - 55 M B1 User Manual

Page 6: 1 air, Speed, 7prerequisite system planning, 8basics of the system planning

6

English 5.906-587.0 Rev. 00 (05/14)

–

Clarify with the customer in detail which requirements

the stationary system should fulfil.

The questionnaire for central vacuuming systems

5.906-589.0 helps, see Chapter "Annex 1 - Question-

naire central vacuuming systems 5.906-589.0“.

–

The system design is based on the number of suction

stations to be operated in parallel and the amount of

material to be transported per vacuuming point.

Flow rate with an air speed of 20 m/s:

Air is the transport medium for the vacuumed material. To

ensure that the vacuumed material is transported in the

entire pipeline network without depositing (material depos-

it) and clogging, a steady air speed must be present in the

network.

The required air speed varies for different vacuumed ma-

terials.

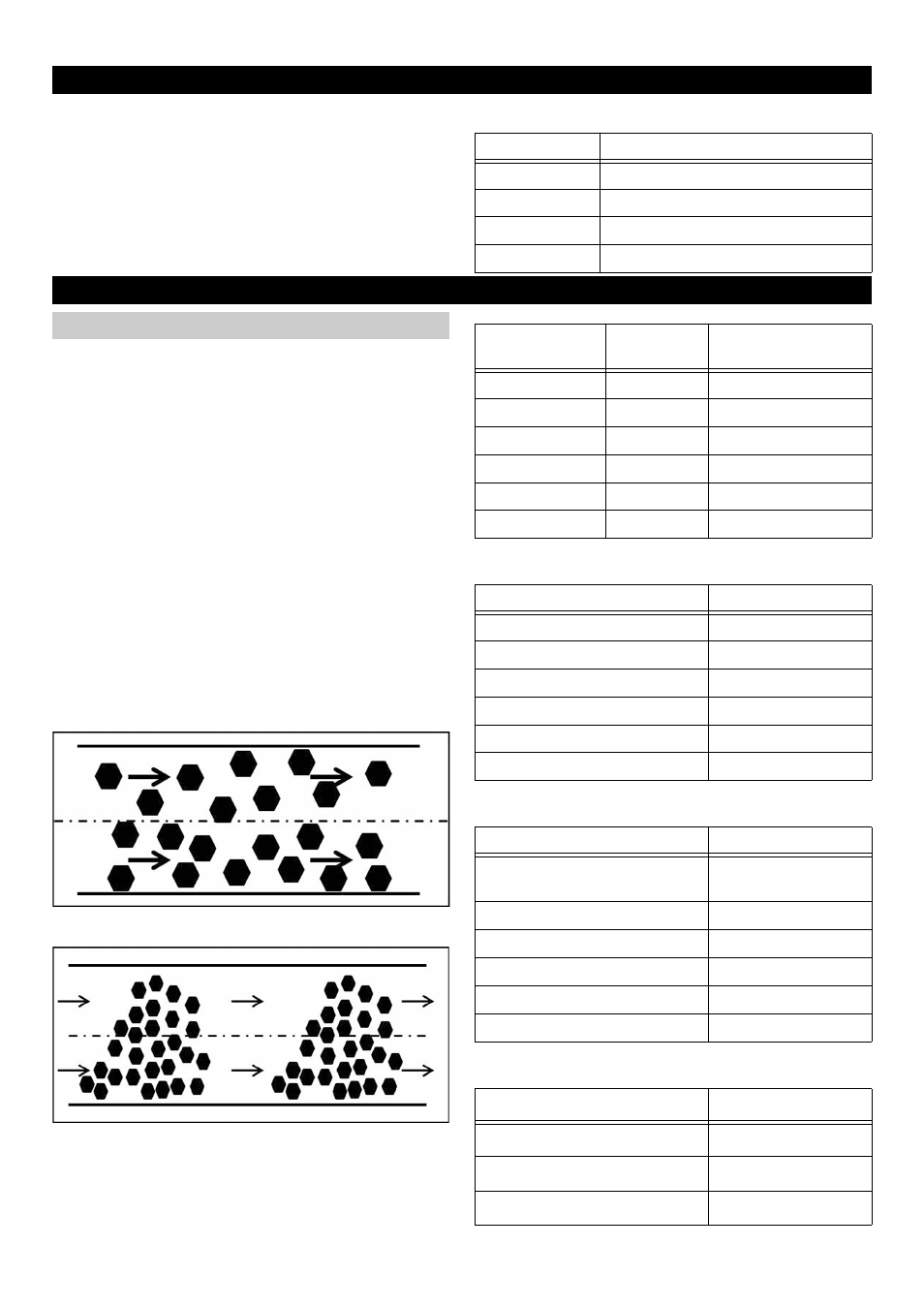

On its way through the line network the individual particle

of the vacuumed material does not fly straight from the

suction station to the disposal container. Thus, it always

requires more time from the vacuuming point to the dispos-

al container than the air speed gives you reason to expect.

For this reason, an after-running time of the vacuum clean-

er must always be provided for to prevent depositing due

to early switch-off.

Note

The perfect and thus targeted conveyance in the pipeline

is the flying transport.

Flying transport

Clogging transport

The smaller values can only be used with lines that are de-

signed in a way that is favourable for the flow, e.g. with

short or vertical lines, elbows with a large radius, fork piec-

es with a small angle.

Area wood

Area metal

Area food

7

Prerequisite system planning

Suction hose

Volume flow (flow rates/h)

DN 42

approx. 90 m³/h

DN 51/52

approx. 140 m³/h

DN 61

approx. 200 m³/h

DN 71/72

approx. 270 m³/h

8

Basics of the system planning

8.1

Air speed

Vacuumed ma-

terial

Dimensions Air speed

Wood chips

50x20x1 mm 22-25 m/s

Sawdust (wood)

Ø 0.7 mm

20-25 m/s

Steel balls

Ø 1 mm

25-35 m/s

Active carbon

Ø 3 mm

20-23 m/s

Plastic granules

Ø 3.5 mm

20-23 m/s

Plastic powder

Ø 0.2 mm

20-25 m/s

Vacuumed material

Air speed

Wood chips with pieces

25-30 m/s

Sawdust damp

22-24 m/s

Coarse wood chips without pieces 18-22 m/s

Wood wool

18-20 m/s

Small wood and planing pieces

16-18 m/s

Finest wood dust

12-14 m/s

Vacuumed material

Air speed

Very coarse metal dust and

chips

20-25 m/s

Coarse metal dust and chips

20-22 m/s

Metal dust, chips

18-20 m/s

Fine metal dust

16-18 m/s

Metal smokes (welding)

14-16 m/s

Finest metal dust

12-14 m/s

Vacuumed material

Air speed

Tobacco dusts

15-16 m/s

Grain and feeding stuff dusts

14-16 m/s

Flour

12-14 m/s