1 step 1, 2 step 2, 3 step 3 – Karcher IV 100 - 55 M B1 User Manual

Page 18: 4 step 4, 1 step, 2 step, 3 step, 4 step

18

English 5.906-587.0 Rev. 00 (05/14)

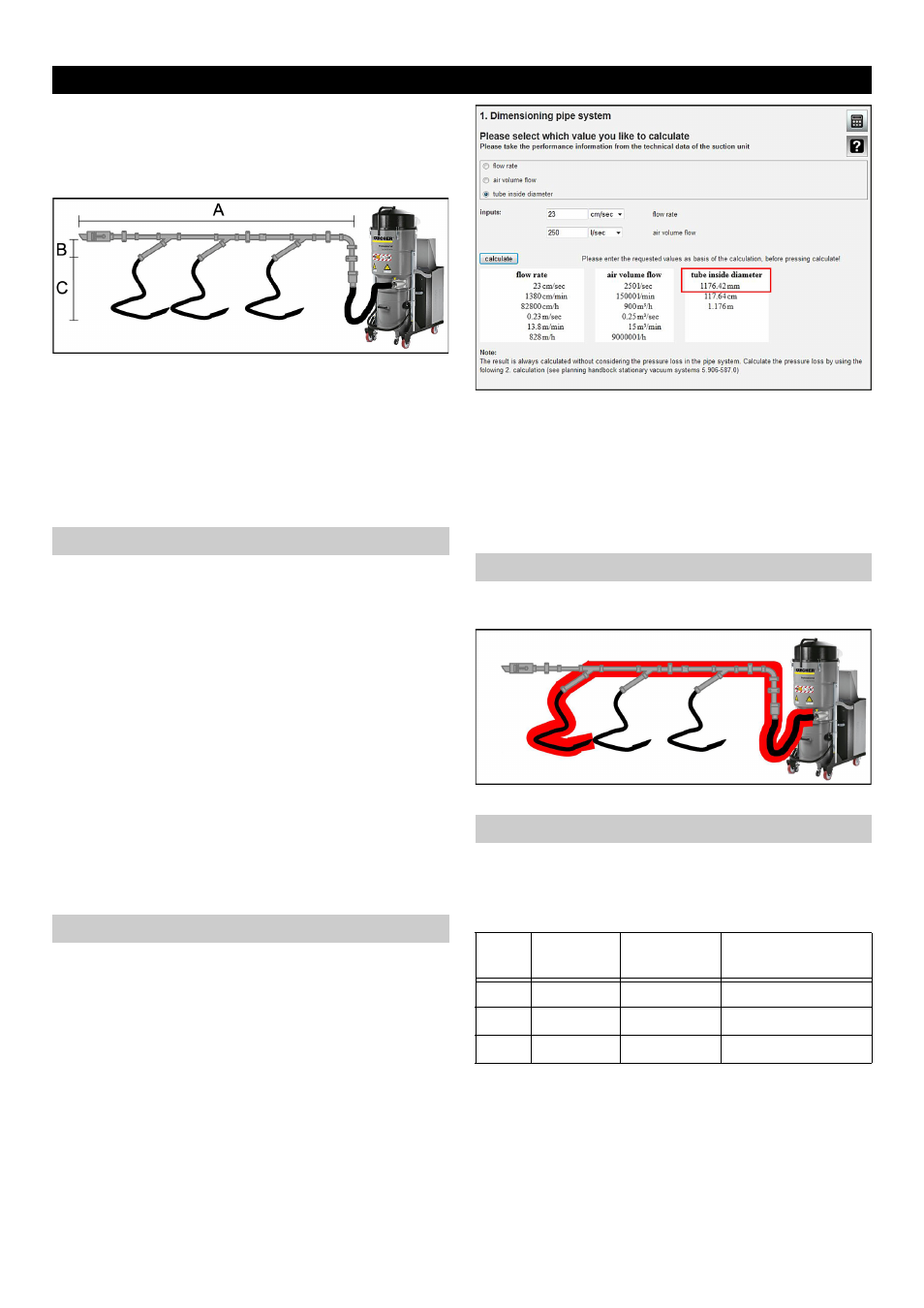

In this example calculation, a suction unit for a shop with 3

work stations is to be designed. The system is to be de-

signed in a way that 2 vacuuming points can be operated

in parallel respectively.

Plastic granules are to be vacuumed up.

A Section: DN 80, 25 m, 3x Y-pieces, 2x 90° bends

B Section: DN 60, 5 m

C Section: DN 50, 5 m suction hose

Note

If they are not in operation, all branch lines are shut off by

means of a slide or a flap. At the end of the collecting pipe

(section A) a false air valve (see setting false air valve)

must be installed as the volume flow is pending there.

The total volume flow of all simultaneously operated vacu-

uming points is calculated for the calculation of the air

speed first.

Note

The air speed results from the available power of the vac-

uum cleaner (technical data), the number of vacuuming

points that are to be operated in parallel and the inner pipe

diameter of the line.

Example:

IV 100/55 as per technical data sheet 139l/s, that equals

500 m³/h (calculated with the calculation tool).

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

500 m³/h / 2 vacuuming points = 250 m³/h per vacuuming

point.

Available volume flow per vacuuming point = 250 m³/h.

Now the maximum pipe diameter is calculated under con-

sideration of the air speed.

Note

Determination of the pipe diameter by matching the avail-

able pipe sizes with the air speed required for the material.

As per the table in Chapter "Air speed", plastic granules Ø

2-3 mm require an air speed of 20-23 m/s.

By means of the calculation tool a max. pipe diameter of

62 mm in the side arm is calculated from the volume flow

250 m³/h and the speed 23 m/s.

The closest diameter in the pipeline programme is DN 60.

As two vacuuming points are operated in parallel, there is

a max. volume flow of 2 x 250 m³/h in the collecting pipe.

For this the calculated pipe diameter with 87.68 mm (with

23 m/s and 500 m3/h) is DN 80.

Identification of the main run in the pipeline system: Main

run is the way that causes the greatest pressure loss.

Main run shaded in red.

Calculation of the air speed in the individual sections of the

main run by means of the calculation tool.

Example:

11 Sample calculation for the dimensioning of the vacuum cleaner

11.1 Step 1

11.2 Step 2

11.3 Step 3

11.4 Step 4

Sec-

tion

Suction

hose

Volume

flow rate

Flow speed

1

DN 80

500m³/h

27.63 m/s

2

DN 60

250m³/h

24.56 m/s

3

DN 50

250m³/h

35.37 m/s