7 step 7, 8 step 8, 9 step 9 – Karcher IV 100 - 55 M B1 User Manual

Page 20: 7 step, 8 step, 9 step

20

English 5.906-587.0 Rev. 00 (05/14)

Recalculation of the volume flow per vacuuming point.

Example:

IV 100/55 as per technical data sheet with a pressure loss

of 128 mbar = ~330 m³/h.

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

330m³/h / 2 vacuuming points = 165 m³/h per vacuuming

point.

Calculation of the actual flow velocities in the sections and

subsequent alignment with the required air speed of the

application, in the example 20-23 m/s.

Example:

In the sections 1 and 2 the required air speed of the exam-

ple cannot be reached. Thus, a more powerful vacuum

cleaner must be used.

Note

In this example a reduction of the pipe diameter would in-

crease the flow velocities in the relevant sections, howev-

er, it would also reduce the dissipation power and thus the

achievable volume flow.

The recalculation takes place analogously to the previous

example.

Step 1

The total volume flow of all simultaneously operated vacu-

uming points is calculated for the calculation of the air

speed first.

Example:

IV 100/75 as per technical data sheet 153l/s, that equals

550 m³/h according to the calculation tool.

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

550m³/h / 2 vacuuming points = 275 m³/h per vacuuming

point.

Available volume flow per vacuuming point = 275 m³/h

Step 2

Now the maximum pipe diameter is calculated under con-

sideration of the flow velocities.

Example:

As per the table in Chapter "Air speed" plastic granules Ø

2-3 mm require a air speed of 20-23 m/s. By means of the

calculation tool a max. pipe diameter of 91 mm is calculat-

ed for section 1 from a volume flow of 550 m³/h and the

speed of 23 m/s. In due consideration of the air speed the

next smaller diameter is chosen from the pipeline pro-

gramme. In the example DN 80.

Step 3

Calculation of the flow velocities in the individual sections

of the main run by means of the calculation tool.

Example:

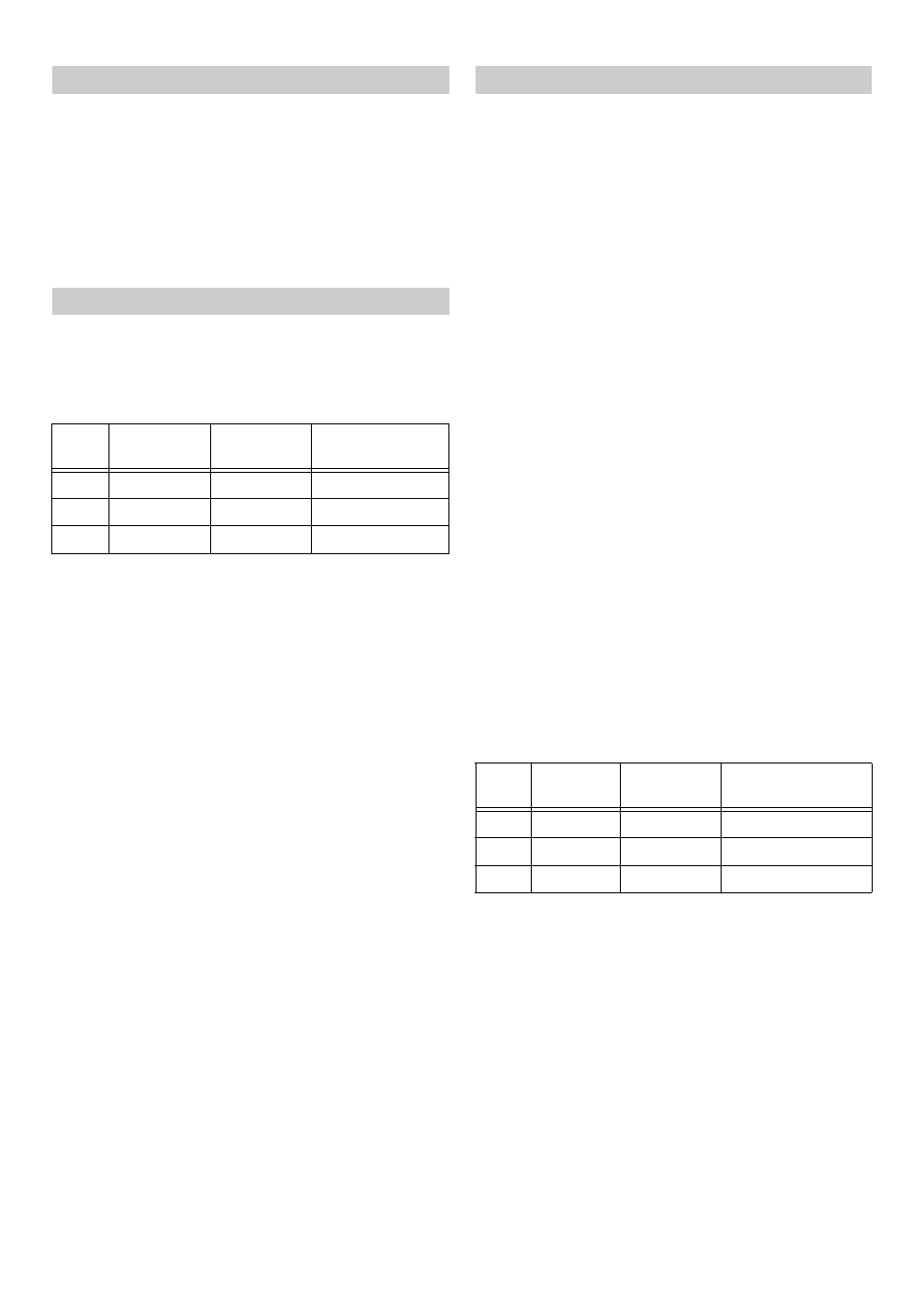

11.7 Step 7

11.8 Step 8

Sec-

tion

Suction

hose

Volume

flow rate

Flow speed

1

DN 80

330m³/h

18.24m/s

2

DN 60

165m³/h

16.21 m/s

3

DN 50

165m³/h

23.34 m/s

11.9 Step 9

Sec-

tion

Suction

hose

Volume

flow rate

Flow speed

1

DN 80

500 m³/h

30.39 m/s

2

DN 60

275 m³/h

27.02 m/s

3

DN 50

275 m³/h

38.90 m/s