ROHM ZG/ZS, ZGU/ZSU, EG/ES - Geared scroll chucks User Manual

Page 17

5.1

Lubrication: appr. every 8 (ZG Hi-Tru) or every 40 ope-

rating hours (other chuck types) at the lubricating nipples

provided for the purpose at the chuck face.

5.2

Partial cleaning: Clean jaws and jaw guides every 100

hours of operation approximately, leaving the chuck on

the machine. Wipe jaws clean (not using compressed

air!), then back them out and thoroughly clean them in

petroleum or petroleum ether. Finally, coat jaws with

fresh grease (F80). Reinsert jaws in the correct se-

quence!

5.3

Full cleaning

5.3.1 Depending the conditions or use, appr. every 50 hours

of operating remove the chuck from the machine, back

out the jaws and disassemble the chuck.

5.3.2 For disassembly, see point 8

5.3.3 Thoroughly clean all parts in petroleum or petroleum

ether. Visually inspect the individual parts. Then coat all

parts with fresh grease.

We recommend our ”F80” special grease, which is

available in tins. This special grease is not flung off even

at high chuck speeds. ”F 80” also resists high surface

pressures and maintains the gripping force of the chuck.

5. Maintenance (valid for all lathe chuck types)

Face plates (four-jaw independent chucks)

UGE/USE with single-piece reversible jaws -- UGU/USU with reversible top jaws

The jaws cen be centered approximately by adjusting

them to the concentric grooves around the face of the

chuck body. Accurate centring requires the use of a dial

indicator. Note that each jaw may only be advanced by

turning the adjusting spindle after the opposite jaw has

been backed out with the adjusting spindle far enough to

provide the necessary clearance to move the workpiece.

For workpieces which are difficult to chuck, the jaws can

be backed out and removed from the faceplate and re-

placed by clamps and bolts which hold the workpiece di-

rectly on the faceplate. The additional T-slots and moun-

ting slots provided in the faceplate serve the same pur-

pose.

If necessary, the faces of all faceplates can be remachi-

ned with a light cut to reduce axial slip.

6. Chucking the workpiece (valid for all lathe chuck types)

Certain criteria must be taken into account when chuk-

king the workpiece.

If workpieces are incorrectly mounted, the danger of

workpieces being flung out of the machine or jaw brea-

kage can arise!!

For more details see the table ”Examples of dangerous

chucking situations and their remedy”.

Attention: For technical reasons the jaw guidings have to

be sharp edged. To avoid injuries safety gloves must be

worn when working at freely accessible jaw guiding edges

(i. e. for jaw changing).

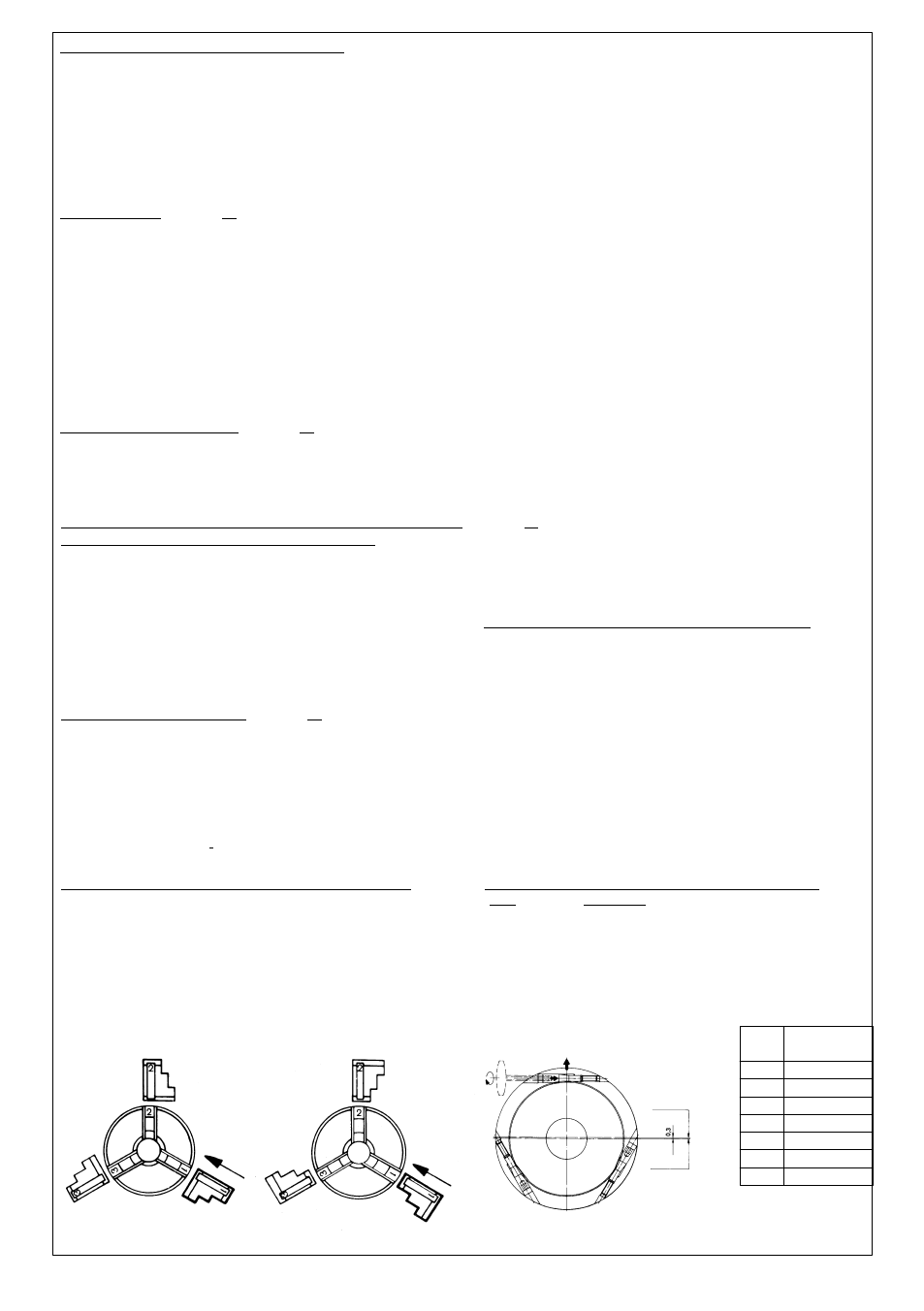

When changing the chuck jaws, adhere to the sequence

1-2-3, i.e. they must be inserted in sequence in the jaw guide

while turning the scroll in such a way that the numbers embos-

sed in the jaws 1 - 2 - 3 are facing the outside (see Fig.).

The jaw steps to the outside (Fig. 1) or to the inside (Fig. 2) must

be taken into consideration.

7. Removing the lathe chuck from the machine spindle head (valid for all chuck types)

7.1 Removing from a spindle head with short taper

7.1.1 Fixture type as per DIN 55021 with stud bolts, DIN 55022

and 55027 or DIN 55029 and ASA B 5.9 D1 (Camlock):

Release the fixing elements to the spindle head at the

back of the chuck.

Do not release any screws at the chuck!

7.1.2 Fixture type as per DIN 55021 and 55026 or ASA B 5.9

A1/A2/B1 - fixture from the front:

Release the chuck mounting screws at the front of the

chuck.

If different screws are mounted on the front of the

chuck, the bigger ones are always the chuck moun-

ting screws!

7.2 Fixture type as per ASA B 5.9 type L (long taper)

Release the union nut at the back of the chuck.

Do not release the backplate mounting screws at the

front of the chuck!

8.1

Back out the jaws.

Adhere to the following instruction sequence wi-

thout fail!

8.2

Loosen the pinion retaining screws

8.3

Remove pinions.

8.4

Unscrew the backplate in accordance with the table

”Possible position of the chuck mounting screws”.

8.5

Remove the backplate and scroll. If they are too firm to

move, insert hard wood or soft metal as an intermediate

element in the jaw recess of the body and dislodge the

back plate and scroll by tapping alternately on the scroll.

In the case of larger chucks, press-off or extractor devi-

ces have to be used to disassemble the backplate and

scroll.

Reassemble in corresponding reverse sequence.

8. Disassembling the chuck (valid for all chuck types)

Remark relating to adapter plate mounting screws

(only applies to ZG Hi-Tru)

When mounting, remember to tighten the adapter plate moun-

ting screws (see page 13 point 11) with the correct torque, as

otherwise precise adjustment by the adjusting spindle is no lon-

ger guaranteed. (See also the illustration below).

Schematic diagram of fine adjustment

Remark relating to lathe chucks with reversible jaws

Insertion in the drilling jaw position

Insertion in the lathe jaw position

(stepped towards the outside) - Fig. 1

(stepped towards the inside) - Fig. 1

Chuck

Tightening torque

dia.

in Nm

80

4

100

4

125

7

160

7

200

11

250

16

315

16

Possible faults and their remedy see page 42

Lathe spindle centre

Gripping centre

Offset

Possible faults and their remedy see page 42

17