ROHM ZG/ZS, ZGU/ZSU, EG/ES - Geared scroll chucks User Manual

Page 14

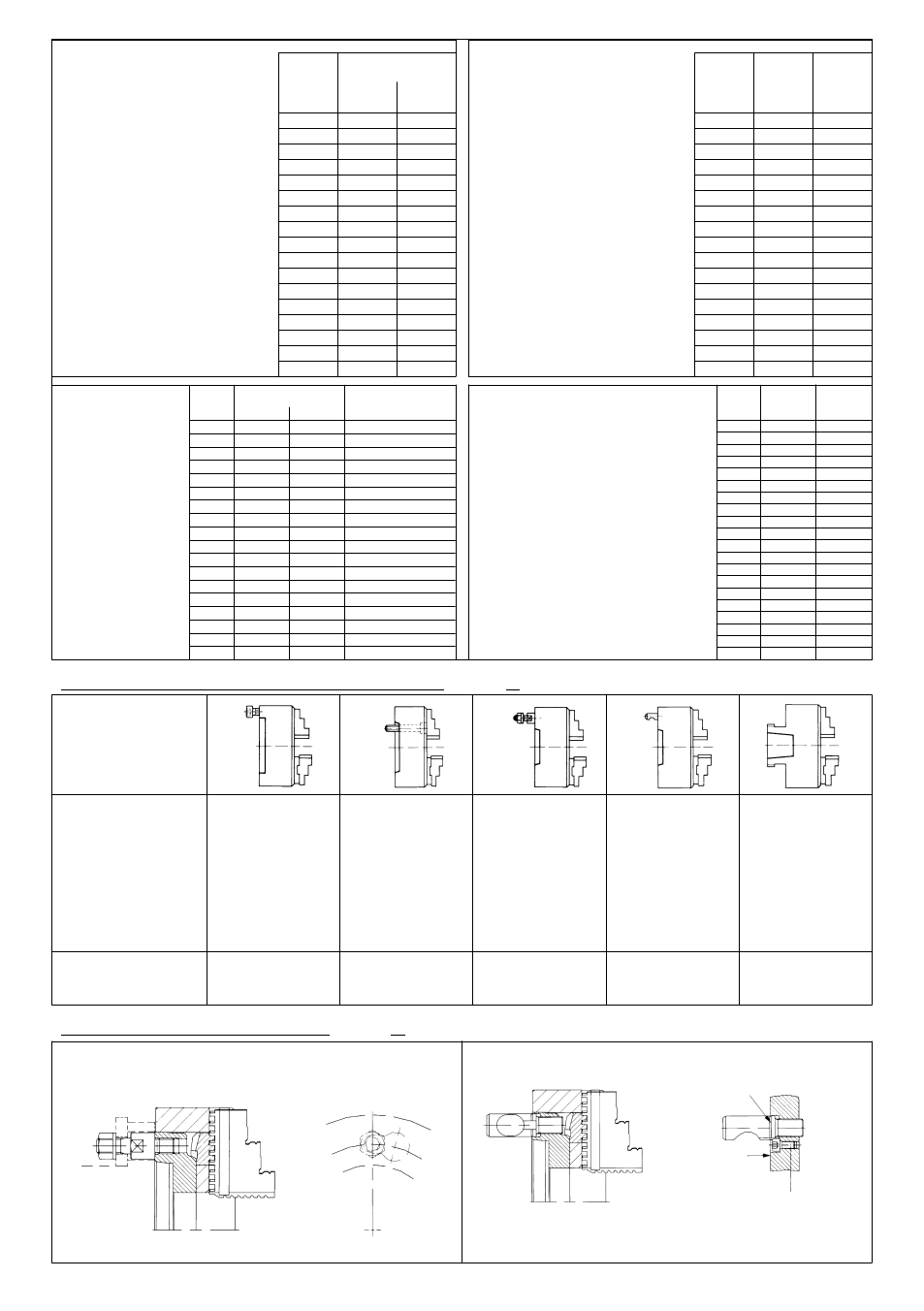

Max. permissible speed for la-

the chucks ZG-ZS, ZGU-ZSU

and ZG Hi-Tru in accordance

with DIN 6350

The maximum permissible speed

is defined so that at maximum

gripping force and when using the

heaviest jaws, a reserve of 1/3 of

the total available gripping force

remains. The jaws may not pro-

ject over the outside diameter of

the chuck. Lathe chucks must be

in flawless condition.

In the case of cast lathe chucks,

the maximum permissible speed

is coordinated to the permissible

peripheral speed for cast iron.

Otherwise, the stipulations of DIN

6281 Part 1 are applicable.

2. Mounting the lathe chuck on the machine spindle head (valid for all chuck types and independent chucks)

Size

3 and 4-jaw chucks

Cast iron

Steel

body

body

74

5000

--

80

5000

7000

100

4500

6300

125

4000

5500

140

3700

5000

160

3600

4600

200

3000

4000

250

2500

3000

315

2000

2300

350

1700

1900

400

1600

1800

500

1000

1300

630

800

850

700

650

800

800

600

700

1000

480

560

1250

380

450

Gripping force for 3-jaw lathe

chucks ZG-ZS, ZGU-ZSU and

ZG Hi-Tru in accordance with

DIN 6350 and EG/ES in accor-

dance with DIN 6351

The gripping force is the sum of all

jaw forces acting radially on the

workpiece at standstill. The speci-

fied gripping forces are guideline

values. They apply to chucks in

flawless condition which are lubri-

cated with grease F80.

Size

Torque

Total

at the

gripping

wrench

force

in Nm

in KN

Machine spindle

DIN 800

DIN 55026,

DIN 55027

DIN 55029

ASA B 5.9

ASA B 5.9

DIN 55022 and

ASA B 5.9

Long taper

A1/A2 metr.

ISO 702/III

D 1 and

and ISO 702/I

ISO 702/II

Fixture

With stud and

Camlock stud

Fixture with

from the front

locknut

union nut

(DIN 55021 with

Cylindrical

stud bolt and nut)

centring rim

type A

Mounting

Fixture

With adapter plate

Short taper

Short taper

Short taper

Long taper

direct mounting

direct mounting

direct mounting

direct mounting

Max. permissible

speed for lathe

chuck EG-ES in

accordance with

DIN 6351

The specified va-

lues are only appli-

cable for workpie-

ces not exceeding

a specific unba-

lance of 25 gmm/

kg.

2.1 Mounting the chuck fixture elements (valid for all chuck types and independent chucks)

Short taper mounting with stud and locknut as per DIN 55027/22

Short taper mounting with camlock ASA B 5.9 D1 and DIN 55029

Note: The camlock stud must be screwed in until the face of the short taper is located

within the marking groove of the camlock stud, and the position of the fixing groove

is in agreement with the threaded hole. Screw in the cheese-head screw as far as

it will go.

Size

Cast body Iron body

3 and 4-jaw chucks

Max. permissible speed for face

plates type UGE-UGU-USE-USU

The specified values are only applica-

ble for workpiece not exceeding a

specific unbalance of 25 gmm/kg.

Size

Cast body Steel body

UGE-UGU USE-USU

74

30

11

80

30

13

100

60

27

125

80

31

140

90

40

160

110

47

200

140

55

250

150

63

315

180

69

350

210

74

400

240

92

500

260

100

630

280

105

700

280

105

800

300

110

1000

450

115

1250

450

115

150

1910

--

200

1430

3000

260

1150

2350

310

960

1970

350

820

1750

400

720

1530

450

640

1360

500

570

1220

560

520

1090

600

470

1020

630

430

970

710

400

860

800

350

765

900

310

680

1000

280

610

1100

260

555

1200

230

510

1300

220

470

1400

200

440

1500

190

410

Marking groove

Face

Cheese-head screw

100

2700

--

125

2400

--

160

2000

3000

200

1600

2450

250

1300

2000

315

900

1350

400

800

1250

500

630

800

630

510

700

14