ROHM ZG/ZS, ZGU/ZSU, EG/ES - Geared scroll chucks User Manual

Page 15

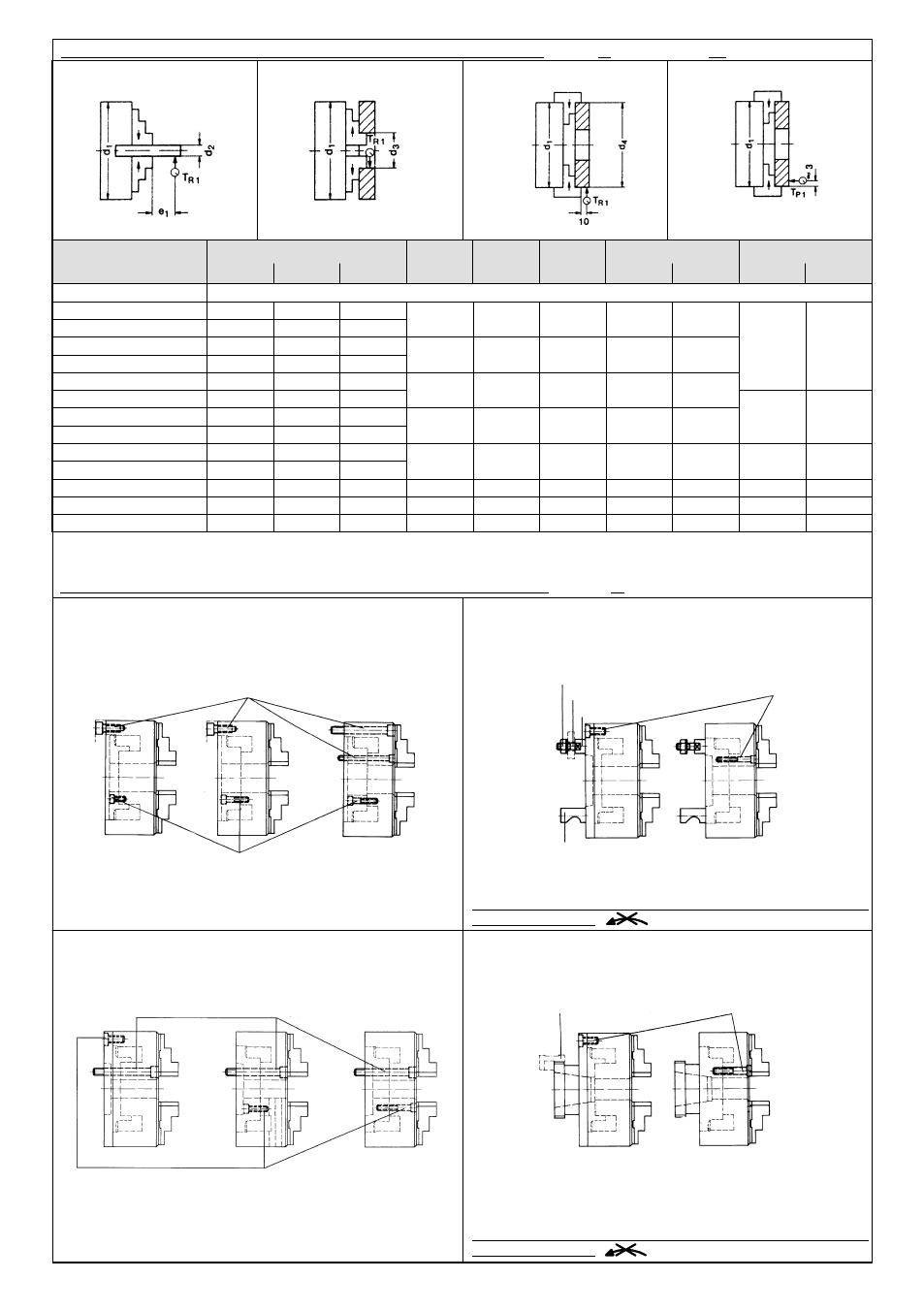

Concentricity tolerance T

R1

/T

P1

relative to the reference surfaces for chuck fitting

(valid for all chuck types, but not for ZGF and EG/ES)

d

1

d

2

d

3

d

4

e

1

Test

1

2

3

4

Class I

Class II

**

Thin

Medium

Thick

T

R1

T

P1

T

R1

T

P1

(74)

10

14

0,05

0,04

80

(85)

10

--

14

100

(110)

10

14

18

125

(140)

18

25

30

0,075

0,04

160

18

30

40

200

(230)

30

40

53

250

(270)

30

53

75

315

53

75

100

0,10

0,07

400

(350)

53

100

125

500

75

100

125

630

75

125

160

800*

--

--

160

200

400

160

0,12

0,06

0,16

0,12

1000*

--

--

400

350

500

160

0,12

0,06

0,16

0,12

1250*

--

--

400

500

700

160

0,16

0,08

0,20

0,16

as agreed

50

80

40

0,04

0,02

80

100

60

0,04

0,03

100

160

80

0,06

0,03

160

250

120

0,08

0,04

200

400

160

0,10

0,05

0,12

0,10

Röhm chucks correspond to precision class I (unless otherwise agreed)

* Chucks 800, 1000, 1250 diameter based on ISO 3089.

** Dimensions given in brackets are intermediate sizes

Possible position of chuck mounting screws and backplate fixing screws

(valid for all chuck types)

1. Chuck with centring rim to DIN 6350 / DIN 6351 or similar to DIN

for threaded flange DIN 800

2. Chuck with short taper, fixture to DIN 55027/22 (stud and lock-

nut) or DIN 55029 and ASA B 5.9 D1 (Camlock)

Release the fixing elements at the back of the chuck.

Caution: Do not slacken the marked backplate screws on the

front of the chuck.

3. Chuck with short taper, fixture to DIN 55026, 55021 and ASA

B 5.9 A1/A2/B1 from the front

4. Chuck with long taper, fixture to ASA B 5.9, type L

Release the fixing elements at the back of the chuck.

Caution: Do not slacken the marked backplate screws on the

front of the chuck.

Release the fixing elements at the back of the chuck.

Backplate mounting screws

Backplate mounting screws

Backplate mounting screws

Backplate mounting screws

Mounting screws

Locknut

Bayonet plate

Stud

Camlock stud

Mounting screws

Union nut

15