Wrong right – ROHM ZG/ZS, ZGU/ZSU, EG/ES - Geared scroll chucks User Manual

Page 12

for refitting work), have to be covered with an anti--seize agent

(grease paste) in the thread area and the head contact area in

intervals of six months.

Under certain circumstances environmental influences, i. e. vibra-

tions, may loosen even tightly fastened screws. For prevention all

safety relevant screws (i. e. clamping device fastening screws,

clamping set fastening screws, or simillar) have to be checked and

-- if necessary -- refastened in regulary intervals.

13. Maintenance work

The reliability of the clamping equipment can only be ensured if

the maintenance specifications in the operating manual are strictly

observed. Please observe in particular:

--

Use the lubricant recommended in the operating instructions for

lubrication (unsuitable lubricant may reduce the chucking force by

more than 50 per cent).

--

In case of manual lubrication, please make sure that all surfaces to

be lubricated are reached (The narrow passages of the built--in

parts require a high injection pressure. For this reason, it is advisa-

ble to use a high--pressure grease gun).

--

For good distribution of the grease in manual lubrication, move the

chucking piston to its final positions several times, re--lubricate

them, and subsequently check the chucking force.

--

For good distribution of the grease when a central lubrication sy-

stem is used, the lubrication pulses should be set to the open

phase of the clamping device.

Prior to series production and between the maintenance intervals a

chucking force measuring instrument has to be used to check the

chucking force. ”It is only a regular check that ensures ideal sa-

fety”.

It is advisable to move the internal moving elements to their final

position several times after five hundred clamping actions at the

latest (Any lubricant pressed away will thus be returned to the

contact surfaces. Thus, the chucking force is retained for a longer

period of time).

14. Collision

After a collision of the clamping unit, it has to be subjected to a

professional and qualified crack detection prior to any further ope-

ration.

15. Replacing the sliding block

If top jaws are attached to the base jaw by means of a sliding

block, an original RÖHM sliding block only may be used.

III.Hazards to the environment

The operation of clamping equipment partly requires the use of various

media for lubrication, cooling, et cetera. As a rule these media are fed

to the clamping equipment through the distribution housing. The most

frequently used media are hydraulic fluid, lubricating oil or grease, and

coolant. When operating the clamping unit, these media have to be

handled with care so that they do not get on the ground and/or into the

water. Warning ! Environmental hazard !

This applies especially

for the assembly / disassembly as residual amounts may still

be in the pipes, piston chambers and/or oil drain screws

for porous, defective or incorrectly mounted seals

or lubricants which escape and/or are ejected from the clam-

ping equipment during operation for design reasons

For this reason, these escaping substances should be collected and

re--used or should be disposed of according to the relevant regulations !

IV.

Safety requirements on mechanically actuated clamping

equipment

1.

The given clamping equipment cannot be monitored for sa

fety by means of limit switches. The operating staff shall have

to be informed of this fact correspondingly.

2. Clamping moments specified shall have to be observed by all

means. If these requirements are not observed, this may lead to

anything from unbalanced masses to the complete loss of the

clamping forces, apart from the loss of accuracy.

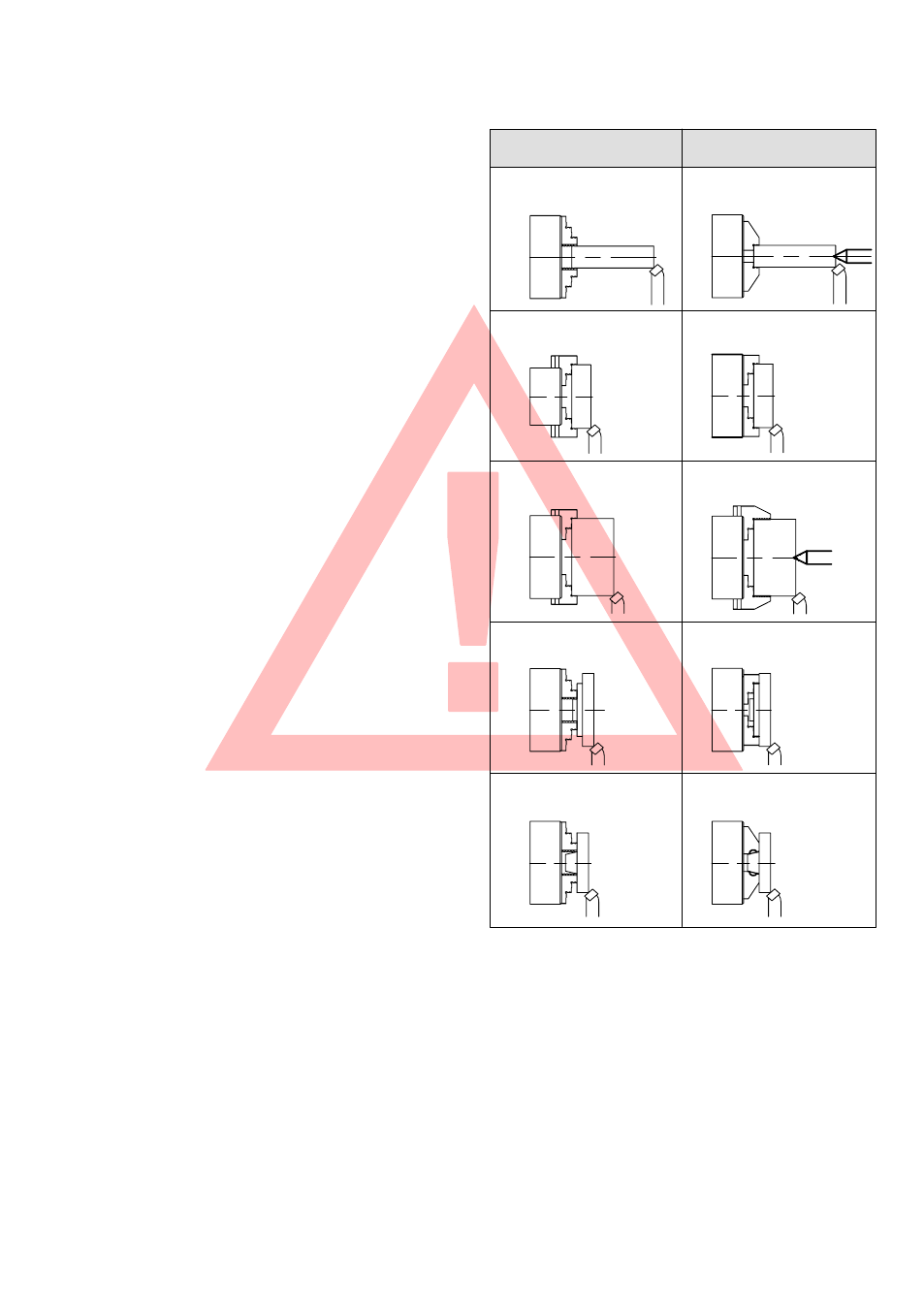

Safety requirements and rules and regulations for the use of manually operated chucks

Wrong

Right

Projecting length of mounted work-

piece too great relative to chucked

length.

Support workpiece between

centres or using a stady

Use a larger chuck

Support between centres, extend

chucking step

Chucking diameter too small

Workpiece has a casting or

forging-related taper

Chuck using self-aligning

inserts

Chuck

using

greatest

possible

chucking diameter

If cutting interrupted, reduse feed and cutting depth.

The illustrated examples do not cover all possible danger situa-

tions. It is the responsibility of the user to recognize possible sour-

ces of danger and to adopt the necessary measures.

Chucking diameter too great.

Workpiece too heavy,

chucking step too short.

Despite all precautionary measures, an element of risk

cannot be excluded.

General Remarks

--

Workpieces may only be mounted in the lathe chuck when

mounted on an adapter plate or on the machine spindle.

--

Do not measure radial run-out and axial slip until after mounting

the chuck on the machine spindle.

--

Never exert force when working with a stiff-running lathe chuck

(mounting distortion, soiling).

--

Never hit the jaws using a hammer.

--

Never use a pipe extension as a wrench.

--

Never select a chucking diameter greater than the chuck diame-

ter. Ensure that the scroll is always covered by the jaw.

--

The jaws may not project beyond the marking groove.

--

Staff entrusted with operation of the lathe chuck must read

through the operating instructions carefully before commencing

work, in particular the chapter on ”Safety remarks”.

12