DME Hydraulic Locking Core Pull Cylinders User Manual

Page 2

DME HYDRAULIC LOCKING CORE PULL CYLINDERS

Specification No. ME-E32-0001(C)

Part No. HLCP-PS01

Page 2 of 12

MOLD DESIGN CONSIDERATIONS (continued):

must “shut off” against an opposing core wall or face, so that plastic flashing is avoided. For proper “shut-off” as described above, recommended preload

amounts are provided in this document. Adjust the spacers prior to final mold assembly. Ensure sufficient pocket clearance around the piston rod and

spacer disk is present for smooth operation.

Positional alignment of the cylinder assembly is achieved by aligning the forward collet of the cylinder body (protrudes forward of the mounting flange)

into the mold plate via the outer diameter of the collet. The collet will protrude past the spacer disk. Rotational alignment of the overall assembly is

achieved via the mounting screws, as rotational alignment is only used to position the proximity sensors and hydraulic fitting connections and/or hoses

within the overall installation. The piston may freely rotate, therefore if rotational alignment of the sliding core is required, rotational alignment of the

sliding core must be achieved via other means.

The positional alignment of the mold’s sliding core is not to be maintained by the cylinder assembly’s piston. The sliding core must have it’s own

provision for positional alignment within the mold plate.

The suggested installation pocket details are based on the cylinder assembly being recessed into the side of the mold plate. It is possible to have the

cylinders assembly mounted fully “proud” of the side of the mold plate, however, positional alignment of the cylinder assembly to the mold plate requires

the forward collet (protruding forward of the mounting flange of the cylinder body) to be recessed partially into the side of the mold. Please adjust the

overall installation as required to fit your application, while maintaining minimum clearances for the hydraulic fitting connections and/or hoses, as well as

maintaining clearances for the proximity sensors. It is the responsibility of the mold designer and/or mold maker to select appropriate hydraulic fittings, as

well as provide necessary pocket clearances (where required) for the hydraulic fittings. Clearance for hydraulic service may need to accommodate hoses

or other features, in addition to the hydraulic fittings themselves. Standard hydraulic thread is NPTF type, but other types are available upon request.

Please see Detail 3.4 for additional notes regarding necessary clearance needed to accommodate the proximity sensors.

Mounting screws provided should not be modified (shortened). Ensure the tapped mounting holes are deep enough to ensure the screw heads can fully

seat on the mounting flange after the screws are installed fully and torque is applied.

SEE NEXT PAGES FOR SUGGESTED POCKET MACHINING DETAILS

TABLE 1.1 — LOAD CAPACITIES FOR THE DME HYDRAULIC LOCKING CORE PULL CYLINDER ASSEMBLY

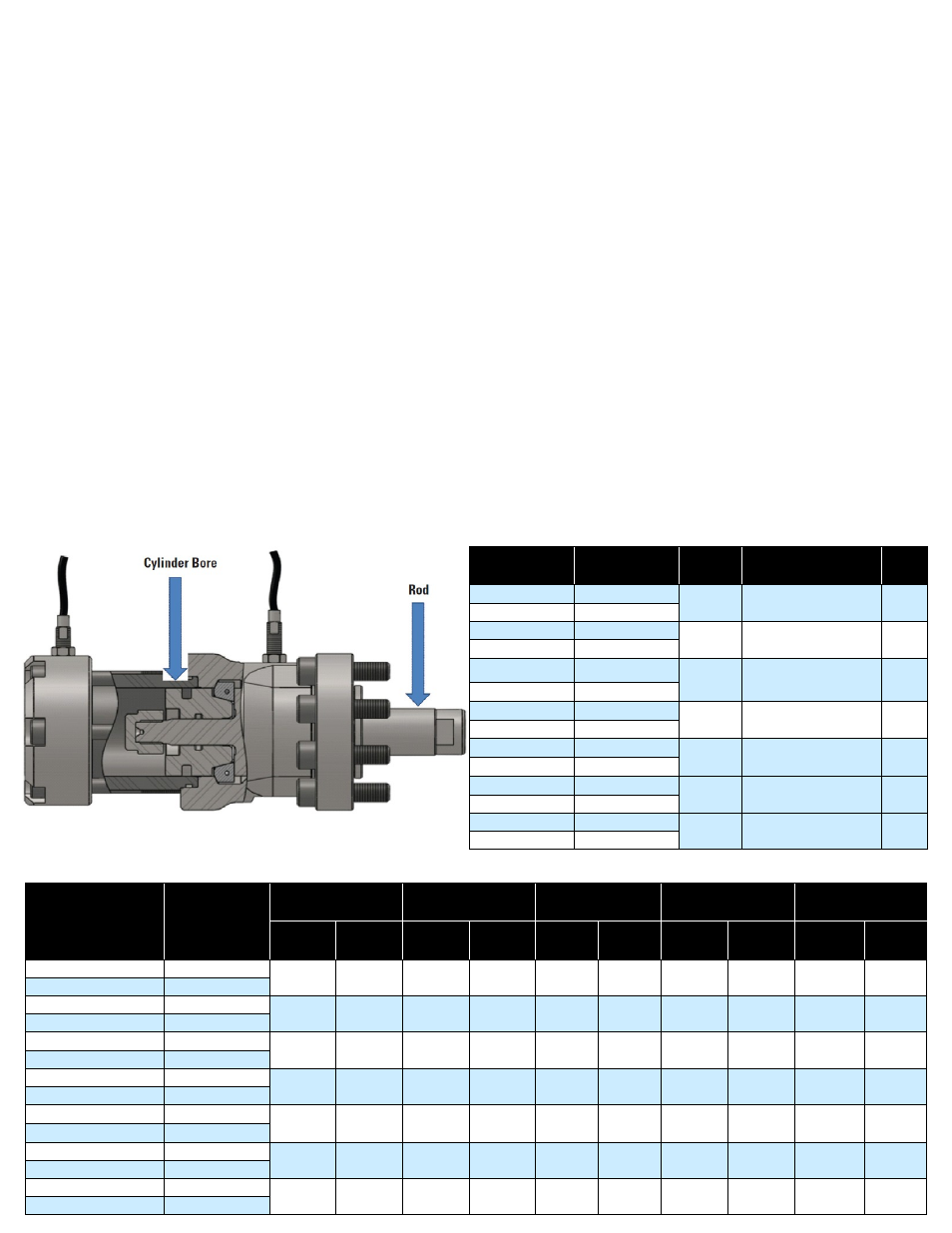

DETAIL 1.1 - HYDRAULIC LOCKIN CORE PULL ASSEMBLY

TABLE 1.0 — HLCP ASSEMBLY SIZES

ASSEMBLY No.

STROKE

ROD DIA. CYLINDER BORE DIA.

NPTF

TAP

HLCP060-1000

25.4 mm (1.00 in)

16 mm

(0.63 in)

30 mm (1.18 in)

1/8

HLCP060-2000

50.8 mm (2.00 in)

HLCP100-1250

31.8 mm (1.25 in)

20 mm

(0.79 in)

36 mm (1.42 in)

1/8

HLCP100-2500

63.5 mm (2.50 in)

HLCP150-1375 34.9 mm (1.375 in) 25 mm

(0.98 in)

45 mm (1.77 in)

1/4

HLCP150-2750

69.9 mm (2.75 in)

HLCP200-1750

44.5 mm (1.75 in)

32 mm

(1.26 in)

56 mm (2.20 in)

1/4

HLCP200-3500

88.9 mm (3.50 in)

HLCP300-2000

50.8 mm (2.00 in)

42 mm

(1.65 in)

71 mm (2.80 in)

3/8

HLCP300-4000 101.6 mm (4.00 in)

HLCP500-2500

63.5 mm (2.50 in)

50 mm

(1.97 in)

84 mm (3.31 in)

3/8

HLCP500-5000 127.0 mm (5.00 in)

HLCP750-3000

76.2 mm (3.00 in)

60 mm

(2.36 in)

105 mm (4.13 in)

1/2

HLCP750-6000 152.4 mm (6.00 in)

ASSEMBLY NUMBER

AT 160 BAR

(2321 PSI)

PRELOAD

Holding Force in kilo

Newton [kN]

Holding Force in

Pound Force [lbf]

Holding Force in

Metric ton [ton]

Holding Force in UK

(troy) ton [ton]

Holding Force in US

(avdp) ton [ton]

Without

Preload

With

Preload

Without

Preload

With

Preload

Without

Preload

With

Preload

Without

Preload

With

Preload

Without

Preload

With

Preload

HLCP060-1000

0.15 mm (0.006 in)

60

35

13,488

7,868

6.12

3.57

5.46

3.19

6.74

3.93

HLCP060-2000

0.20 mm (0.008 in)

HLCP100-1250

0.15 mm (0.006 in)

100

50

22,480

11,240

10.20

5.10

9.11

4.55

11.24

5.62

HLCP100-2500

0.20 mm (0.008 in)

HLCP150-1375

0.10 mm (0.004 in)

150

65

33,720

14,612

15.30

6.63

13.65

5.91

16.86

7.31

HLCP150-2750

0.15 mm (0.006 in)

HLCP200-1750

0.15 mm (0.006 in)

200

110

44,960

24,728

20.39

11.21

18.20

10.01

22.48

12.36

HLCP200-3500

0.20 mm (0.008 in)

HLCP300-2000

0.15 mm (0.006 in)

300

160

67,440

35,968

30.59

16.31

27.31

14.57

33.72

17.98

HLCP300-4000

0.20 mm (0.008 in)

HLCP500-2500

0.20 mm (0.008 in)

500

300

112,400

67,440

50.98

30.59

45.51

27.31

56.20

33.72

HLCP500-5000

0.30 mm (0.012 in)

HLCP750-3000

0.20 mm (0.008 in)

750

400

168,600

89,920

76.48

40.79

68.27

36.41

84.30

44.96

HLCP750-6000

0.30 mm (0.012 in)