DME 250 Series User Manual

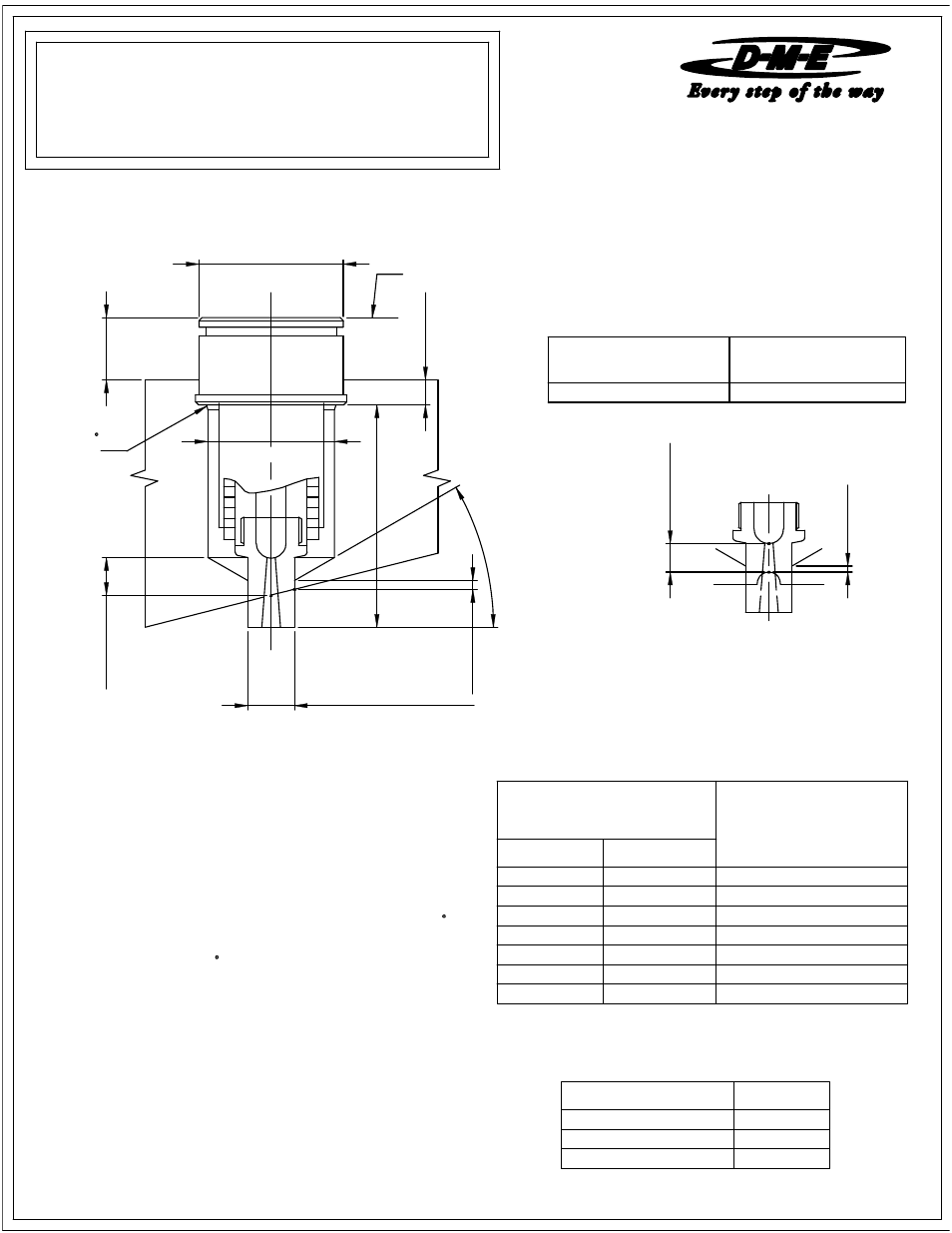

250 series extended, Sprue gate nozzle, Installation data

1.501

0.000

+0.001

DIA.

0.

125 MI

N

.

"A

" + B

E

0.

250 MI

N

.

"N"

DIA.

BORE TO FIT TIP

"("T" DIA.) +0.0005 / -0.0000

0.

250 MI

N

.

A

FTE

R CUT

0.

250 MI

N

.

A

FTE

R CUT

0.

080 MI

N

.

3

0

.0

°

0.

080 MI

N

.

ESG2/IS

to the nominal "A" dimension. The formula

For selection of gate diameter it is important to take into consideration the materials flow characteristics, shear rate of resin, molding conditions, fill time

requirements, gate vestiage, wall thickness and configuration of part to be molded. Situations requiring high injection velocities must be considered

"T" DIA.

CATALOG NUMBER

EHA0005

4.250

CIA0004

CIA0006

EHA0006

WIRING INFORMATION

Square Coil Heaters and Cast-In Heaters are supplied with 2"

See material manufactures literature for further information regarding material to be molded.

when selecting small gate diameters. High injection rates may require larger gates due to shear heat build up (e.g. high weight thin wall applications).

expansion of the nozzle (BE) at a given temperature must be added

EHA0004

To compensate for the nozzle's growth when heat is applied, the linear

1.187

1.250

3.750

CIA0003

1.000

below shows how to figure

250 SERIES EXTENDED

CIA0005

EHT0013

0.500

EHT0014

0.750

EHT0015

08-08

4.750

"N' Dia. (max.)

Square Coil or Cast-In

"N' Dia. (min.)

Square Coil or Cast-In

5.750

EHA0007

CIA0007

6.750

and Tip-assembly.

NOTE: Nozzle Assembly requires Nozzle Sub-assembly

Before installing a Extended Sprue Gate Nozzle, it is important to take

SPRUE GATE NOZZLE

boring depth (dimension "A" + BE).The tip of the nozzle will now be

iron (magnetic).

REFER TO : MINI PRINT # 1800

follow the information below

INSTALLATION DATA

temperature of 500

ME-0741-PS-553-D

CHAMFER

The above information is only given as an example. variations may occur

0.030 X 45

2 power leads are Multi Color. 1 ground lead is GREEN.

EXAMPLE: Given a 3 inch "A" dimension, with a nozzle set point

F).

1 T/C lead is WHITE and negative (

MANIFOLD LINE

Thermocouple is "J" Type. Thermocouple is supplied with 36" leads.

prestripped 36" long leads.

F:

be necessary to obtain an empirical factor.

BE = 3 x 0.00000633 x (500 - 68) = 0.008

-

Thus "A" + BE will be 3.008

BE="A" dimension x 0.00000633 x (Nozzle set point temperature - 68

Formula for determining this expansion factor is as follows:

flush with cavity line.

1 T/C lead is BLACK and positive (+)

Heaters are 240 VAC.

constantan (non-magnetic).

)

Note:

based on mold configurations and cooling factor. In some instances it may

MACHINING DETAILS

the nozzle's expansion factor into consideration. For best results, please

SPRUE GATE TIP SUB-ASSEMBLY

NOTE:

NOZZLE SUB-ASSEMBLY

CATALOG NUMBER

"A" DIMENSION

FOR NOZZLE ASSEMBLY

SQ.COIL HTR. CAST-IN HTR.

EHA0001

CIA0001

2.750

EHA0002

CIA0002

3.250

EHA0003