DME 625 Series Ring Gate Nozzle User Manual

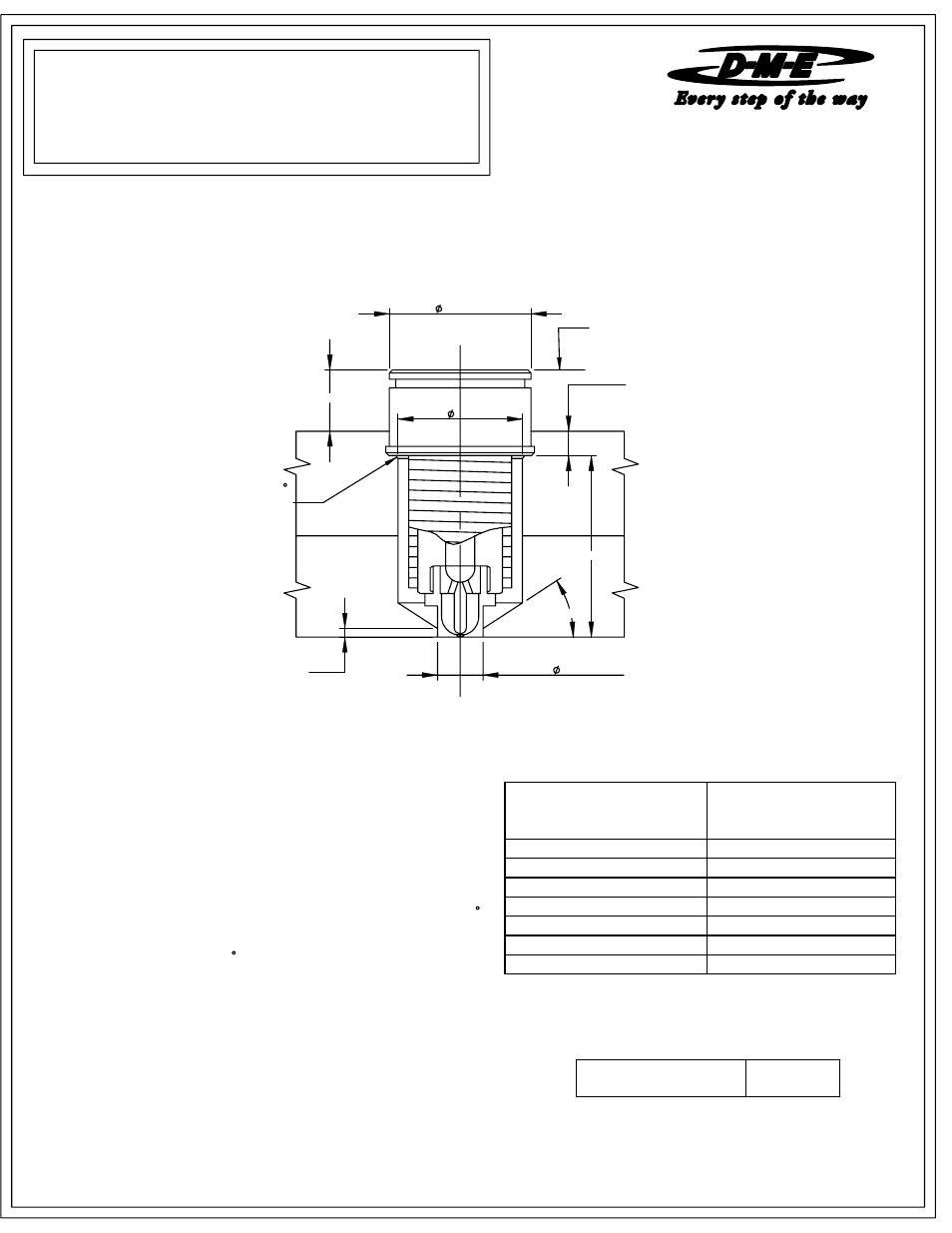

Series 625 ring gate nozzle, Machining & installation data

3.001

0.000

+0.001

0.125 MIN.

0.250 MIN.

1.0005

0.0000

+0.0005

2.12

0.080

30°

"A" + BE

0.03 X 45

CHAMFER

MANIFOLD LINE

based on mold configurations and cooling factor. In some instances it may

ME-0741-PS-991-D

RG6/IS

SERIES 625

RING GATE NOZZLE

MACHINING &

INSTALLATION DATA

NOTE:

Before installing a Ring Gate Nozzle, it is important to take the

nozzle's expansion factor into consideration. For best results, please

follow the information below

RING GATE TIP SUB-ASSEMBLY

NOTE: Nozzle Assembly requires Nozzle Sub-assembly and Tip-assembly.

To compensate for the nozzle's growth when heat is applied, the linear

expansion of the nozzle (BE) at a given temperature must be added

to the nominal "A" dimension. The formula below shows how to figure

boring depth (dimension "A" + BE). The tip of the nozzle will now be

flush with cavity line.

Formula for determining this expansion factor is as follows:

Thus "A" + BE will be 3.008

BE="A" dimension x 0.00000633 x(Nozzle set point temperature - 68 F).

EXAMPLE: Given a 3 inch "A" dimension, with a nozzle set point

temperature of 500 F:

BE = 3 x 0.00000633 x (500 - 68) = 0.008

Note: The above information is only given as an example. variations may occur

be necessary to obtain an empirical factor.

NOTE: Dimensions are shown in Inches.

EHA 0016

4.000

EHA 0017

5.000

EHA 0018

6.000

EHA 0019

7.000

EHA 0020

8.000

EHA 0021

9.000

CATALOG NUMBER

EHT 0040

EHA 0022

10.000

08-08

NOZZLE SUB-ASSEMBLY

CATALOG NUMBER

"A" DIMENSION

FOR NOZZLE ASSEMBLY