DME DMAX 625 Series High Performance User Manual

DME Hardware

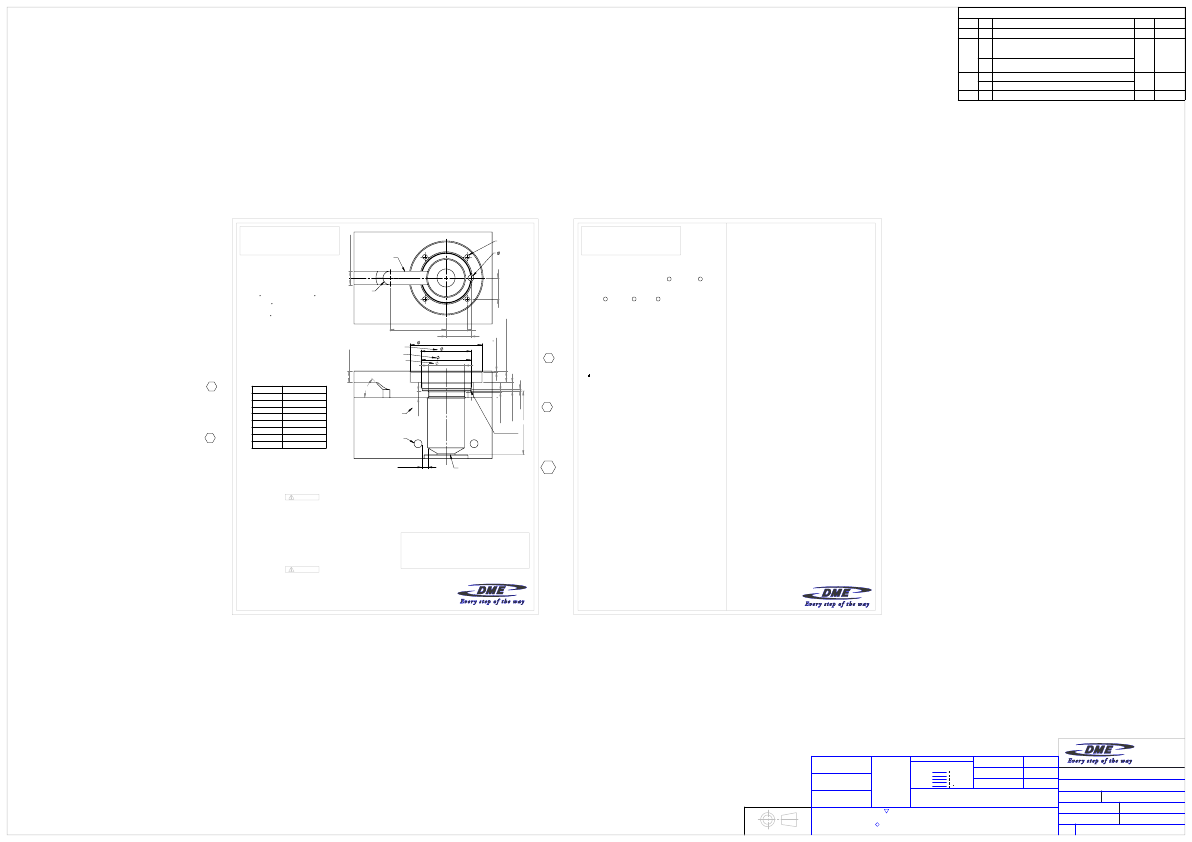

2.125 MIN

0.469

-0.001

0.000

0.633

MIN - 1.283 MAX

(5)

0.06

x 45

45°

0.69

MIN

0.375

"A" + BE

0.110

(5) 0.06 x 45

2.756

0.000

+0.001

2.80

4.000 LOCATING RING BORE

0.31 MIN

R 0.030 MAX

MIN WIRE CHANNEL

TCP

"A" PLATE

WATER LINE

HEAD BORE

HEATER CLEARANCE

DANGER

IMPORANT SAFETY INFORMATIOn

The High Performance Hot Sprue Bushing includes electrical elements and may

contain molten plastic at elevated temperature and pressure. To avoid injury,

exercise caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should be read

before using this product. Failure to do so can result in serious injury or death.

Failure to comply will result in serious injury or death

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only with

proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.Do not operate this

equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout / tag out

before servicing this device. Do not connect temperature sensor to electrical

power. It will damage the product and could cause fire, severe injuries or even

death.

If green ground wire present, wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low voltage or power to drive out

residual moisture before applying full power. Failure to do so may cause damage

to this product.

Failure to comply can result in serious injury or death

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing this system.

Physical contact with molten plastic may reult in severe burns. Proper protective

equipment, including eye protection, must be worn.

This product has heated surfaces. Use caution when operating and servicing the

system to avoid severe burns. Proper protective equipment should be worn.

DME SHALL NOT BE LIABLE FOR FAILURE TO FOLLOW THE

ENCLOSED INSTRUCTIONS AND SPECIFICATIONS. DME

HEREBY TO DISCLAIM ALL IMPLIED WARRANTIES. INCLUDING

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL DME BE RESPONSIBLE FOR

LOSS OF USE, REVENUE OR PROFIT, OR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGE.

HEAD BORE CLEARANCE

PSDMAX625 3-14 ME-100005-0827(D)

625 SERIES HIGH PERFORMANCE

HOT SPRUE BUSHING

INSTALLATION DATA

OPERATING PROCEDURE

The bushings are supplied with a High Performance heater with a Type "J"

thermocouple.

It is recommended to use a DME closed loop Temperature Controller for

optimum temperature control with a Step Smart R or Smart Start R . These

systems will allow heater to dissipate any moisture and then change

automatically to set point. It is essential to use controllers with the proper

voltage and wattage capabilities. The voltage and wattage of each heater is

clearly marked on the heater tag.

Step Smart R , Smart Start R and DME R are all registered trademarks of

DME Co. LLC.

RECOMMENDATIONS AND GUIDELINES

1. Proper protective equipment, including eye protection and gloves, must

be worn.

2. Bushing head must be held in such a manner to keep it from rotating.

Aligning heater leads into wire channel and if tip has a runner or angle

aligning these to cavity surface. This may be done by machining the Top

Clamp Plate for a key (customer to suit) to align with the flat on the bushing

head or circle interpolate the plate for the flat.

3. Tip and bushing threaded area must be clean of any material before

assembly.

4. Apply an anti-seize compound on the tip threads.

5. Screw tip into the shank of the bushing. Torque and loosen tip from the

bushing 3 times making sure that there is good contact between the tip and

the bushing and that the tip will not rotate any more when torqued. Use

30 5 ft. lbs. of torque with a six point deep well socket. If applicable, after

assembled into mold, customer can then mark tip for runner or angle. Upon

removal of tip and runner or angle is machined onto tip, the tip can then be

retorqued and assembled back into mold. Insuring alignment between

runner or angle in the tip and the runner or angle in mold.

6. Carefull attention should be taken to the heater/thermocouple leads as

damage could occur when working on the bushing assembly.

7. Slip-On Rear-Load High Performance Heaters must be installed on the

bushing before installing bushing in the mold as follows:

a. Slide heater (lead end towards head) onto bushing body.

b. Align heater leads within the center of bushing head wire slot.

c. Snap end of heater onto bushing body.

8. Place bushing into mold aligning heater leads into wire channel of Top

Clamp Plate.

9. Secure locating ring over bushing onto the Top Clamp Plate.

10. Wire heater power and thermocouple leads into DME electrical

connector (see Wiring Information).

11. The power and thermocouple leads may be spliced in wiring channel for

ease of heater replacement. Leads may be spliced using Thomas & Betts

PA plastic insulated disconnects:

Male Cat# 18RA-251T

Female Cat# 18RA-2577

12. Secure wires in Top Clamp Plate wire channels with DME Wire Covers.

13. For removal of bushing from mold, follows these steps:

a. Remove DME connector from power.

b. Remove mold from press.

c. Remove locating ring and wire covers.

d. Unwire heater and thermocouple leads from DME connector or unplug

insulated disconnects.

e. Remove bushing from mold.

14. Place bushing head into a vise with copper jaw caps. Caution do not

over tighten.

15. For removal of tip from bushing, a six point deep well socket is

recommended. The bushing must be at processing temperature and the

heater should be turned off before removing tip counter-clockwise from

bushing.

16. For safety, heater should only be removed when cooled down to room

temperature.

17. Grip end of heater by hand and pull heater off bushing shank. Caution

do not twist heater off bushing body, this can damage heater leads that are

still in the bushing head wire slot. If heater will not slip off, place the tip end

of a small flat screw driver behind the clip of the heater, which is at the tip

end of the heater. Carefully remove the pressure of that clip allowing the

heater to slip off the bushing body. Do not bend clip.

See Packing Slip # PSHOT625 for

625 Series Tips and machining details

WARNING

NOTES:

1.

All dimensions are in inches.

2. The expansion factor must be taken into considera-

tion prior to maching and installing bushing. This factor

(BE) must then be added to the nominal "A" dimension.

Formula for determining this expansion is as follows:

BE = "A" dimension x 0.00000633 x (nozzle set point -

68 F) Assuming the mold is at 68 F during

operation. If mold temperature is different, sub-

stitute 68 F with actual mold temperature.

EXAMPLE: Given a 3.543 Inch "A" dimension, with a

set point of 500 F

BE = 3.543 x .0000063 x (500-68) = 0.010

Thus "A" + BE will be 3.553

The above information is only given as a example,

variations may occur based on mold configuration and

cooling factor. In some instances, it may be necessary

to obtain an empirical factor.

3. For protection of heater leads, use wire covers to

contain leads in wire channel 3.00 minimum between

covers.

4. Break all sharp edges in wire channel for protection

of heater leads.

PSDMAX625 3-14 ME-100005-0827(D)

625 SERIES HIGH PERFORMANCE

HOT SPRUE BUSHING

INSTALLATION DATA

B1

B2

C1

C2

1.174

1.378

3.50 MIN

0.75

WIRE SLOT

1.174

8.00 DWL

(OPTIONAL FOR

ANTI-ROTATION)

(4) 5/16-18 UNC

FULL

RADIUS

BUSHING HEATER

CABLE EXIT

WIRING INFORMATION

Heaters are supplied with 2" prestripped 36" long leads.

Heaters are 240 VAC

2 power leads are Multicolor

1 ground lead is Green color

Thermocouple is "J" Type.

Thermocouple is supplied with 36" long leads

1 T/C lead is White and negative (-) constantan (non-magnetic)

1 T/C lead is Black and positive (+) iron (magnetic)

Note:

Thermocouple color code described above follows international IEC 584-3

convention. The thermocouple is "J" Type. The white (negative) wire used in

IEC 584-3 convention is REVERSE of the white (positive) wire used in

ASTM E230 (white = positive, red = negative) convention.

D

REVISIONS

ECN

REV

DESCRIPTION

BY

DATE

A

Released as per NDR-M0564

JA

7/25/2011

M3957

B1

Changed catalog no. from: DMAX 14090 To: DMAX 16090

DMAX14115 DMAX16115

DMAX14140 DMAX16140

DMAX14165 DMAX16165

DMAX14190 DMAX16190

JA

9/26/2011

B2

Added to chart: DMAX16215 8.464in (215.00mm)

DAMX16240 9.449in (240.00mm)

DMAX16265 10.433in (265.00mm)

M4134

C1 Changed from: .69 To: .633

JA

7/9/2013

C2 Changed from .409 To: .469

M4817

D

Changed from: PSFLH625 To: PSHOT625

JA

3/25/2014

ASSEMBLY

"A"

DMAX16090

3.543 in (90.00mm)

DMAX16115

4.527 in (115.00mm)

DMAX16140

5.512 in (140.00mm)

DMAX16165

6.496 in (165.00mm)

DMAX16190

7.480 in (190.00mm)

DMAX16215

8.464in (215.00mm)

DMAX16240

9.449in (240.00mm)

DMAX16265

10.433in (265.00mm)

ME-031/2008-09-18

4-15-2011

Pruden

DESCRIPTION

ASSEMBLY NAME

SCALE

US PART NUMBER

ME PROJECT

DWG NO(REV)

A1

MECHANICAL ENGINEERING

29111 STEPHENSON HWY.

MADISON HEIGHTS

MICHIGAN 48071

U.S.A.

PH: +1-248-398-6000

FX: +1-248-544-5707

625 Series Hot Sprue Bushing Packing Slip

Externally Heated System

ME-100005

PSDMAX625

ME-100005-0827(D)

1:1

GLOBAL FAMILY CODE

ME-G43

REVISION: PRIMARY.SECONDARY

LIFE CYCLE STATUS

D

RELEASED

2. MAXIMUM ALLOWED

SURFACE FINISH

ROUGHNESS TO BE

Ra 1.6 MICROMETER

UNLESS OTHERWISE

SPECIFIED.

1. REMOVE ALL BURRS

AND BREAK ALL SHARP

EDGES 0.35 MAXIMUM

UNLESS OTHERWISE

SPECIFIED.

Key Characteristic - -a product characteristic whose variability could significantly

affect product function and/or customer satisfaction.

Safety Characteristic - -a product characteristic whose variability could significantly

affect the products safety or compliance with governmental regulations.

This document is proprietary to D-M-E Company and is not used, circulated, reproduced,

copied or disclosed in any manner whatsoever without the prior specific written permission

of an authorized official of the D-M-E Company.

ANGLES

0.000

0.00

0.0

DATE

DATE

DATE

APPROVED

CHECKED

DRAWN

0 30'

0.013

0.13

0.3

0.8

0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ARE:

DIMENSIONS ARE IN MILLIMETERS

NOTES:

PLOT DATE

HEAT TREAT

MATERIAL

Adas

Popsecu

3-28-2011

4-15-2011

THIRD ANGLE PROJECTION