DME Gate-Mate Bushing Sub-Assemblies User Manual

Gate-mate bushing sub-assemblies, Installation data, Gmb9998

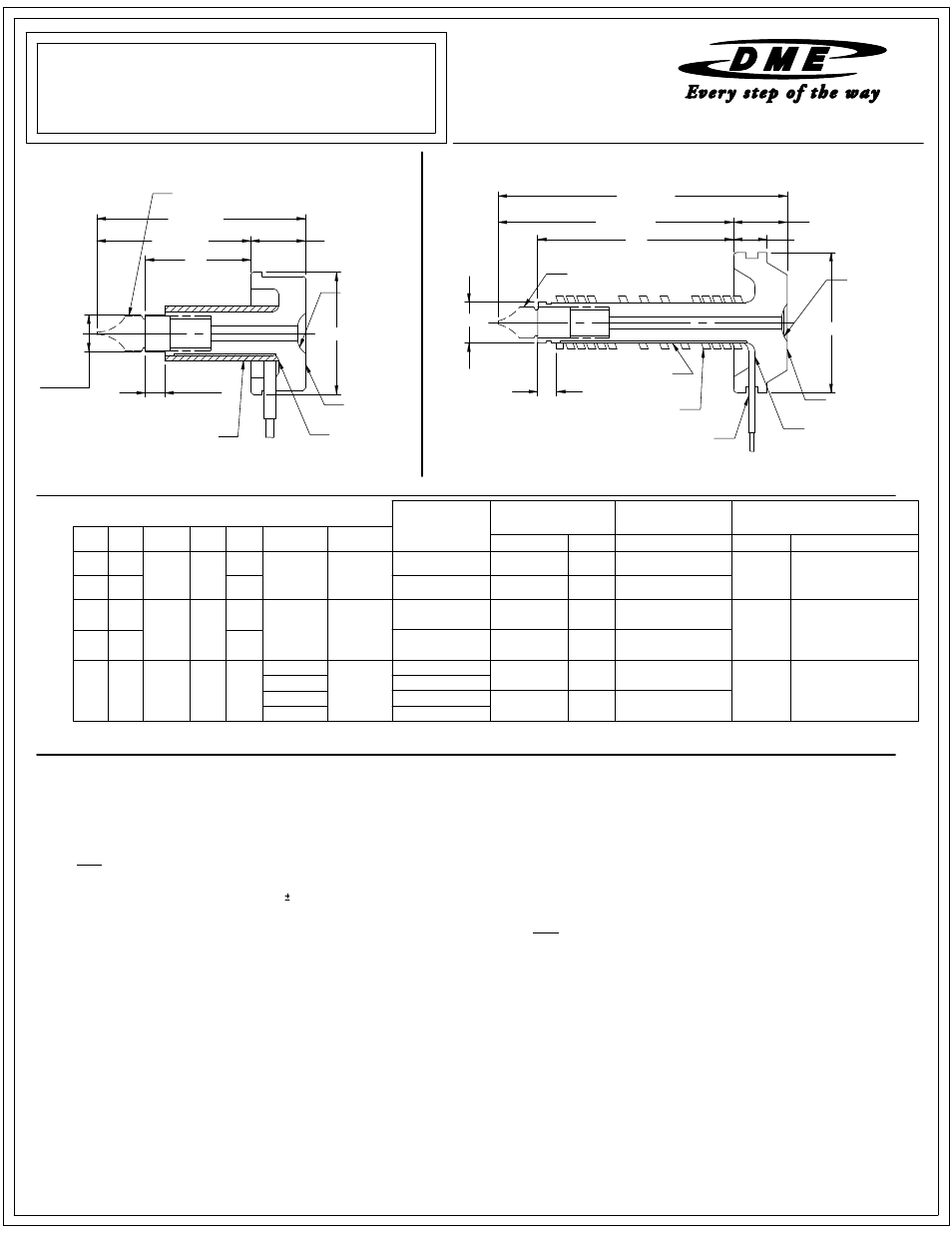

1.062

L (REF.)

B DIA.

0.250 *

D

A (REF.)

C DIA.

0.562 REF.

THERMOCOUPLE

SQ. COIL HEATER

HEATER AND THERMOCOUPLES LEADS

EXIT THRU SLOT IN BUSHING BODY

BOTTOM OUT COIL

HEATER ON NOZZLE

BODY

BUSHING

BODY

TIP SUB-ASSEMBLY

MEDIUM AND JUMBO GATE-MATE ASSEMBLY

* DIMENSION INDICATES CORRECT HEATER DISTANCE.

SPH. RAD

0.6250

C DIA.

L (REF)

A (REF)

D

B DIA.

0.200 *

TIP SUB ASSEMBLY

MINI GATE-MATE SUB-ASSEMBLY

* DIMENSION INDICATES CORRECT HEATER DISTANCE

CAST-IN HEATER WITH INTERNAL

THERMOCOUPLE (SHOWN) OR SQUARE

COIL HEATER AND THERMOCOUPLE.

SPH. RAD.

BUSHING

BODY

BOTTOM OUT

HEATER ON

BUSHING BODY

NO HOLE * * * *

GMB0020

SCH3142

315

TC-9600

GMB0116

SCH0004

Please read carefully before installing bushings.

INSTALLATION DATA

GATE-MATE BUSHING SUB-ASSEMBLIES

GMB9998

02-10

ME-0739-PS-311-E

GMB0112

225

TCG0100

GMT0100

GMT0101

STANDARD

WEAR RESISTANT *

GMB0117

GMB0111

CAST-IN

225

N/A

length to be a direct replacement for the standard and jumbo tips. Given an

using the GMT0007 thru hole tip. These tips are designed 0.040 shorter in

thru hole tip and use the GMT0004 jumbo tip machining dimensions when

10. Use the GMT-2 standard tip machining dimensions when using the GMT0302

diameter may result in a larger gate vestige.

the gate may have to be enlarged to achieve greater flow. This increase in

the best gate vestige.Depending on part configuration and plastic being used,

the cavity at processing temperature. The smallest gate diameter will yield

9. For best processing and lowest gate vestige, tip must be 0.000 to 0.005 into

SQ. COIL HEATERS INCLUDE INSTALLATION/REMOVAL WRENCH

* * SEE RECOMMENDATIONS AND GUIDELINES NOTE # 8

* WEAR RESISTANT TIP IS RECOMMENDED FOR ABRASIVE MATERIALS.

* * * SEE RECOMMENDATIONS AND GUIDELINES NOTE # 11

* * * SEE RECOMMENDATIONS AND GUIDELINES NOTE # 10

Sharp tip.

8. A 0.030 min dia. gate is recommended when using the GMT0301 Super

as this is a seal-off dimension to fit the bushing's seat.

seal-off area and threaded areas before reassembling.

7. Machine the "B" diameter + 0.0005 -0.0000 directly into the cavity carefully,

6. Machine the "C" diameter directly into the mold to fit the bushing's head.

damage could occur when working on bushing assembly.

5. Careful attention should be taken to the heater and thermocouple leads as

for the medium and 17 mm deep well 6 point socket for the jumbo.

well 6 point thin wall socket for the Mini, 11 mm deep well 6 point socket

when reassembling. For protection of the tip point, use a 9 mm deep

5 ft-lbs for all other tips

25 ft-lbs for the wear resistant tips, and 35

4. Tip must be torqued into the bushing body using a torque wrench at 20 to

lubricate or use anti-seize compound on the threads.

NOT

3. Do

dropped or strikes a rigid material. Treat tip like a glass or ceramic material.

2. Careful attention should be taken to the tip as damage could occur if tip is

heat to transfer into the tip before molding.

17. Wait a minimum of 5 minutes after set point has been achieved for sufficient

material flow.

14. When bushing must be recessed deeper than the "W" dimension, alter the

16. Provide a gate dimple on core/cavity opposite gate. This will allow for best

into the locating ring.

to suit application.

clamp plate and route wires through that plate. A wire slot may be machined

bushing would extend beyond the clamping plate, add another plate to the

15. Route wires through wire channel in clamping plate. In the event that the

"W" and the 0.219 dimension to suit the application.

Note: Dimensions shown in Inches.

ring. Locating rings are supplied with additional stock allowing for machining

13. Constrain bushing in the mold by clamping with the appropiate D-M-E locating

12. Provide maximum water cooling in the cavity insert around gate.

mold and wire heater and thermocouple into the terminal mounting box.

hole and clean all chips from tip and body. Reassembly body back into the

remove tip from body. Remove any burrs around 0.125 diameter

JUMBO

NOT

Do

tip at the marked location. See packing slip number GMT-PS for more details

Remove body from the mold and machine a 0.125 diameter hole into the

location of flow hole on the circumference of the tip and mark that position.

cavity insert should be removed to expose tip from parting line. Determine

The gate-mate body must be keyed into the nozzle plate. "A" plate and/or

11. Using the GMT0303 no hale tip allows for flow hole allignment in the cavity.

gate for the GMT0007 thru hole tip.

is recommended for the GMT0302 thru hole tip and a 0.080 to 0.125 diameter

best processing and lowest gate vestiage a 0.030 to 0.060 diameter gate

"A" dimension of 2.000 + BE (NOT 1.960 + BE) using a GMT0302 tip. For

1. Bushing (single-application) body must be cleaned of any material in the

RECOMMENDATIONS AND GUIDELINES

3.562 2.500

L

DIM.

A

DIM.

B

DIA.

C

DIA.

D

DIM.

SPH. RAD.

BUSHING

STYLE

4.562 3.500

1.2500

1.645

2.625

2.645

1/2 & 3/4

FLAT

1/2

FLAT

MINI

1/2

1.094

1.500

0.6250

1.375

2.000

1.645

2.375

3.437

MEDIUM

1/2 & 3/4

2.645

2.156

0.7500

3.375

4.437

SUB-ASSEMBLY

REFERENCE

SQ.COIL HEATERS

(240 VAC)

THERMOCOUPLES

(40" LEADS)

SUB-ASSEMBLY

TIPS

CAT. NO.

WATTS

CAT. NO.

CAT. NO.

STYLE

GMB0114

SCH0001

315

TC0001

GMT0004

GMT0006

GMT0007

STANDARD

WEAR RESISTANT *

THRU HOLE * * *

GMB0113

SCH0002

315

TC0002

GMB0030

SCH3242

315

TC-9700

GMT-2

GMT0300

GMT0301

GMT0302

GMT0303

STANDARD

WEAR RESISTANT *

SUPER SHARP * *

THRU HOLE * * *