Troubleshooting, Maintenance – JKS 3104 User Manual

Page 3

JKS3100 - JKS3104

JKS Quicker Disconnect Installation

Page 3

IMPORTANT: DO NOT exceed Maximum Length (mea-

sured from center-to-center of bushings) indicated for

your part number.

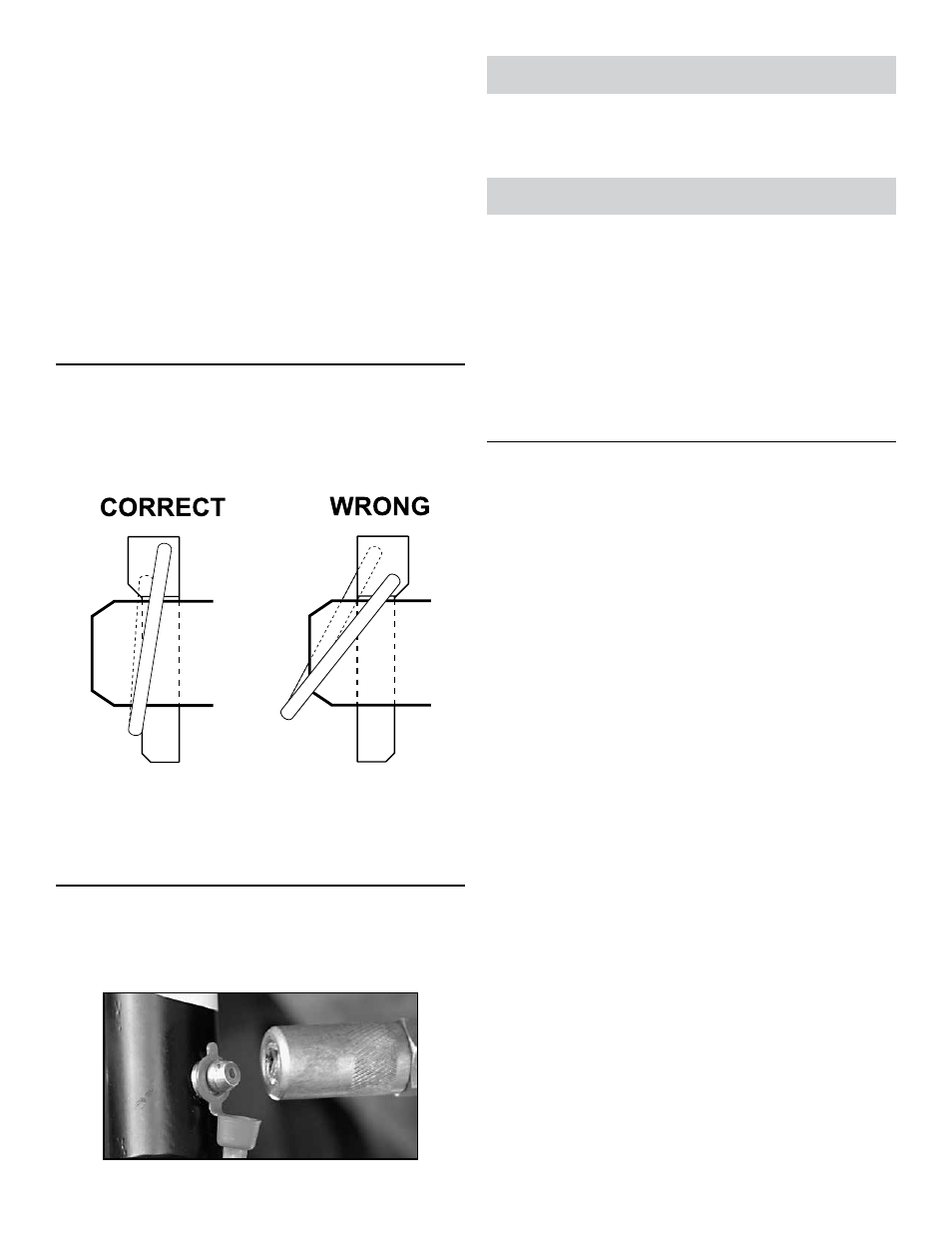

Adjust the length of your Quicker Disconnects until

swaybar is at the Ideal Angle or within Acceptable

Range. Vehicle must be at normal ride height and

located on level ground.

Once adjusted, lay Quicker Disconnects on a flat

surface and tighten Jam Nuts (L) firmly against the

Lower Ends (H).

IMPORTANT: Bushing cradles at both ends of Quicker

Disconnect must remain parallel with each other when

Jam Nut is tightened.

5. INSTALL QUICKER DISCONNECTS

Slide Upper End (G) and Lower End (H) of Quicker

Disconnect onto the tapered Stainless Steel Posts

(C).

Insert Click Pins (D) as illustrated to secure.

IMPORTANT: When properly installed, the ring on the

Click Pin will “snap” against the shaft of pin. When in-

stalled backwards, the ring does not fit snugly against

shaft.

6. LUBRICATE QUICKER DISCONNECTS

Lubricate all Grease Zerk fittings (E) on the Quick-

er Disconnects immediately after installation using

common wheel bearing grease or equivalent.

Troubleshooting

If swaybar does not rotate freely, remove from vehicle,

clean and apply rubber lubricant to chassis-mounted bush-

ings, and reinstall.

Maintenance

It is important to lubricate Quicker Disconnects frequently

for the first three (3) months after installation to evacuate

contaminants that may build up during break-in period.

After break-in period, Quicker Disconnects should be lubri-

cated regularly as part of vehicle maintenance schedule.

Regular cleaning with pressurized water is recommended

to maximize ease of operation and reliability. Always lubri-

cate afterwards to evacuate any moisture.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/11/2013