JKS BSE251 User Manual

Page 4

JKSBSE251

JKS Hydraulic Bump Shocks Installation

4 Page

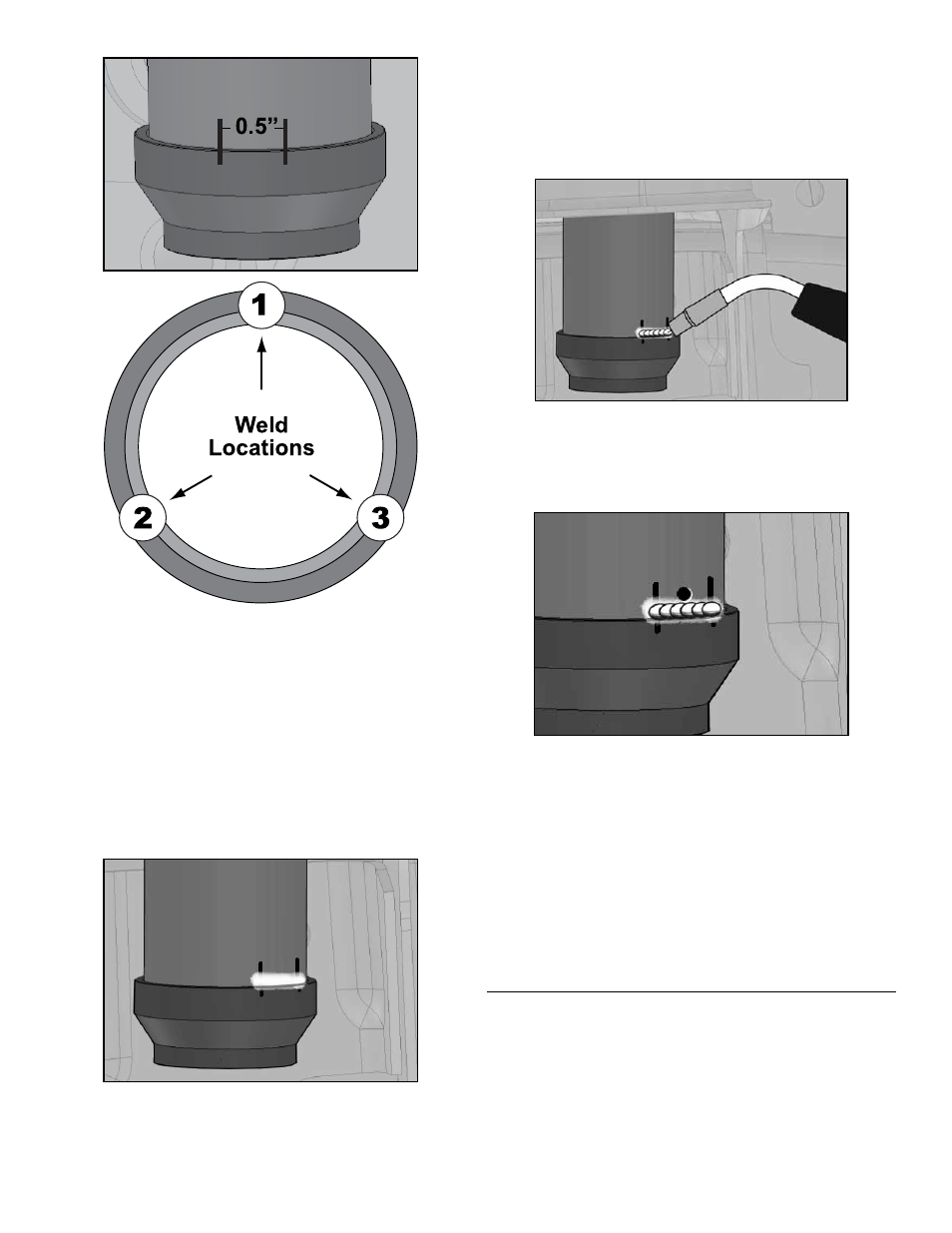

Remove Jounce Adapter (C) from Chassis Tube

(D) and locate the weld location markings on both

components.

Remove the zinc plating from the marked locations

on the Jounce Adapter (C).

HINT: Emory cloth or a

suitable stripping tool is useful for removal of coat-

ings. Make sure bare metal is completely exposed

and free of contaminants to ensure proper weld

penetration.

Reposition the Jounce Adapter (C) on the Chassis

Tube (D), making sure the locations prepped for

welding are in alignment.

Tack weld the Jounce Adapter (C) to the Chassis

Tube (D) at each location. Make sure the adapter

has remained fully seated against the tube before

proceeding.

Next, weld a 1/2” long bead over each tack weld

to ensure the Jounce Adapter (C) remains secured

to the Chassis Tube (D).

HINT: As long as you

achieve proper weld penetration on the adapter

and spring retainer, it is not necessary to weld

around the entire perimeter.

Allow the welded sections to cool and then drill a

3/8” hole through the Chassis Tube (D) immedi-

ately above one of the welds.

HINT: The purpose

of the hole is to facilitate the evacuation of any

moisture that may collect inside the tube.

To prevent corrosion, it will be necessary to paint

all exposed surfaces on the Jounce Adapter (C)

and Chassis Tube (D). Prepare for painting by

thoroughly cleaning any dirt, debris or deposits

from the area.

HINT: A clean piece of emory cloth

or equivalent is useful for preparing the area to be

painted.

Completely cover the exterior of the Jounce

Adapter (C) and all exposed metal on the Chassis

Tube (D) with satin black spray paint. Protect inner

threads of adapter from overspray.

5. INSTALL BUMP SHOCK ASSEMBLY

Apply anti-seize lubricant to internal threads of

Jounce Adapter (C) and Bump Shock Nut (B).

Completely thread the Bump Shock Nut (B) onto

Bump Shock Assembly (A).

Thread Bump Shock Assembly (A) into Jounce

Adapter (C) as far as possible.