Parts, Installation – JKS BSE251 User Manual

Page 2

JKSBSE251

JKS Hydraulic Bump Shocks Installation

2 Page

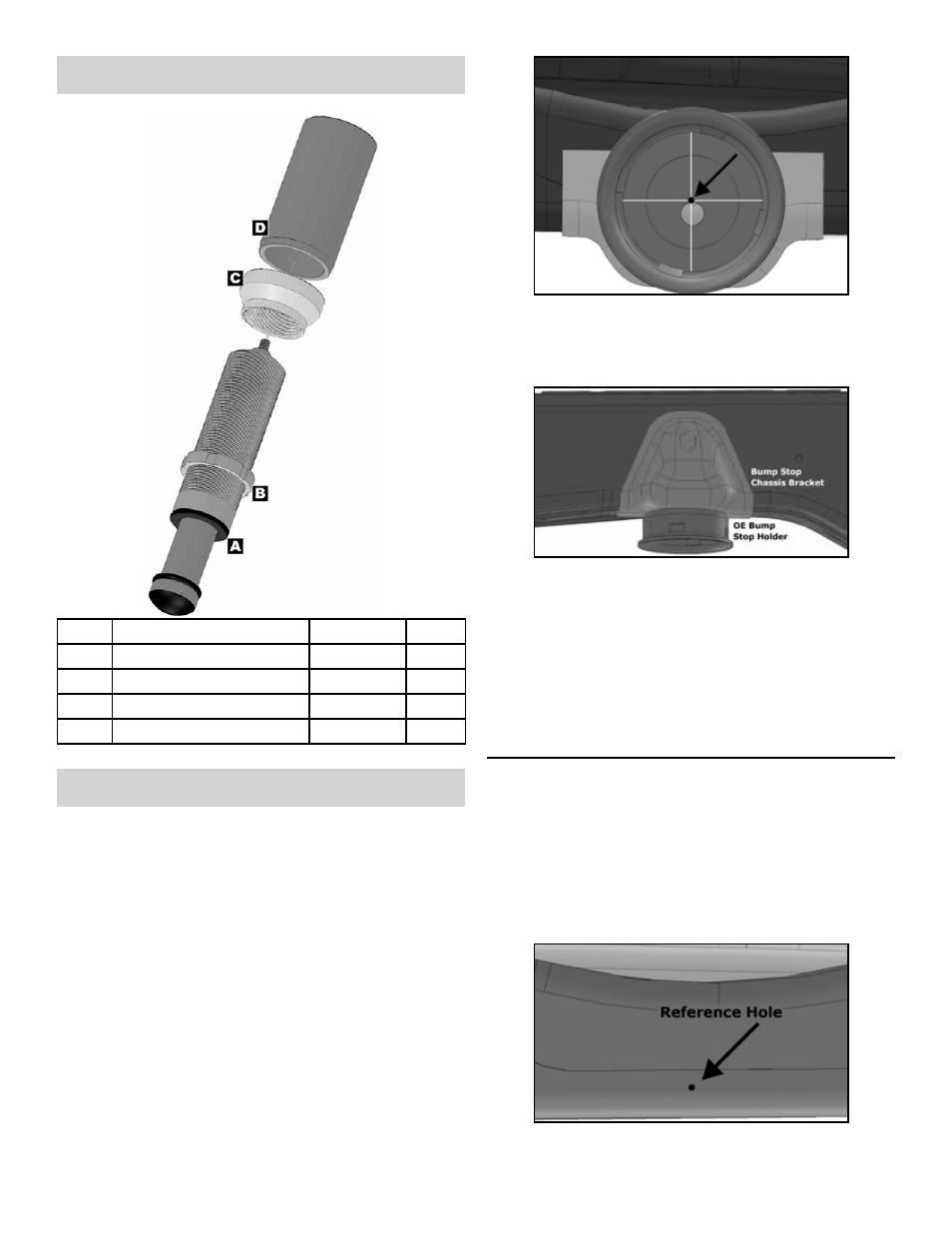

Parts

Description

Part #

QTY

A

Bump Shock Assembly

RFC/BS02

2

B

Bump Shock Nut

RFC/SN50

2

C

Jounce Adapter

03154

2

D

Bump Shock Chassis Tube

03155

2

Installation

1. PREPARE VEHICLE FOR CHASSIS

MODIFICATIONS

Remove rear track bar, shocks, coil springs, and

any other components that prevent you from ac-

cessing the factory rear bump stop holders.

HINT:

You will need to access this part of the chassis

from multiple directions so make sure you have

plenty of freedom to work.

Drill a small hole exactly through the center of

the factory upper bump stop holders and into the

chassis. Make sure drill is square with chassis.

HINT: This provides a reference point to work from

during installation, as center of BumpShock must

remain at the same centerline as the factory bump

stop.

Remove the factory upper bump stop holders from

the chassis brackets.

HINT: The bump stop holder

is welded to the chassis bracket and must be cut

free.

Next remove the factory bump stop brackets from

the chassis.

HINT: The bracket is welded to the

chassis along its perimeter. It must be carefully

removed without gouging or otherwise damaging

the chassis.

With the bump stop holders and brackets re-

moved, clean the chassis of any remaining weld

material until smooth.

2. FRENCH CUT CHASSIS

The chassis rails must be frenched to accept the supplied

Chassis Tubes (D). When executed correctly, the Hydrau-

lic BumpShock will be positioned on the same centerline

as the OE bump stop holder (identified by the previously

drilled reference hole). Also, the BumpShock must contact

the center of the landing pad on the axle when the suspen-

sion is compressed.