Preparing the work space – HP Integrity BL870c Server-Blade User Manual

Page 18

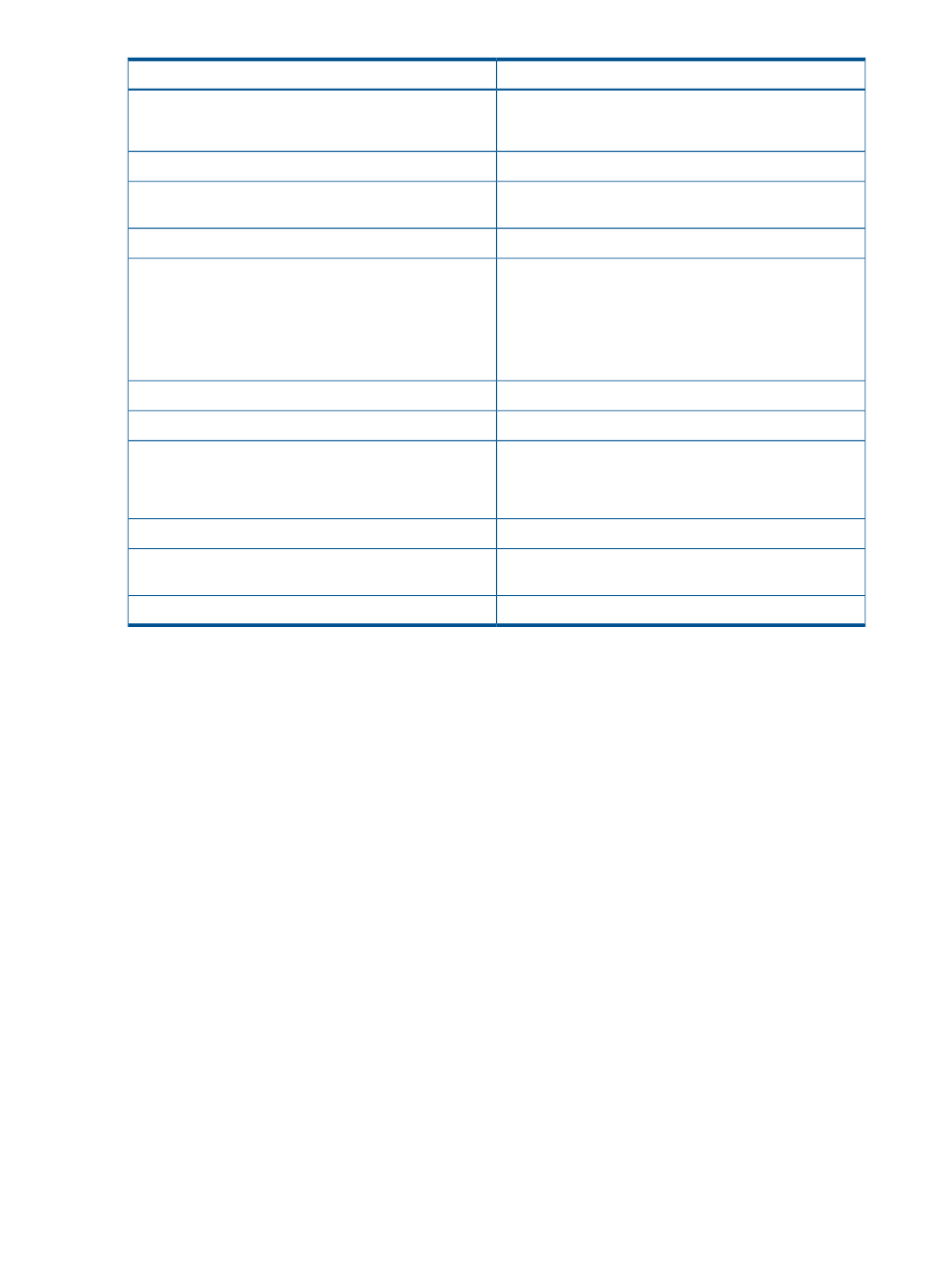

Purpose

Tool

9/16-inch socket wrench with 1/2-inch drive ratchet

•

Install caster supports on racks

•

Remove screws that secure racks to their shipping pallets

Install baying kit when bolting cabinets together

5/8-inch hex driver

Raise or lower casters (all commercial cabinet types,

seismic rack)

3/4-inch wrench (quantity: two)

Adjust rack leveling pads in seismic rack

5/16-inch allen key

Install anchor bolts in the concrete floor for seismic rack

19-mm wrenches:

•

0-150 ft-lb torque wrench with 19-mm, deep socket,

1/2-inch driver for use with anchor bolts

•

19-mm “crows foot”, 1/2-inch driver (adapter)

•

19-mm open end wrench

Adjust rack leveling pads in seismic rack R2

6mm (15/64") hex key (allen key)

Install caster on seismic rack R2

9-mm (15/64") hex (allen key)

17-mm (11/16") wrench

•

Install caster on seismic rack R2

•

Remove screws that secure R2 racks to their shipping

pallets

Raise or lower casters (seismic rack R2)

23-mm (7/8") socket wrench

Install anchor bolts in the concrete floor for seismic rack

R2

24-mm (1") wrench

Attach enclosure ground cables to grounding rails

10-mm socket driver

For cabinets that you bolt to the floor, you need certain tools and equipment for marking the cabinet

positions and drilling the anchoring holes in the concrete floor. See

.

Preparing the Work Space

Before beginning the installation of a seismic rack, verify the existence and location of electrical

feeds. Check that the installation site provides all required branch circuit breakers, power feeds,

and ground feeds. These cables must be provided by the customer. Lugs for fastening the cables

to the system are either in kits provided by the installer or attached to the racks before shipment.

18

Installation Preparation Steps