4 installation preparation steps, Checking general safety, Gathering necessary tools – HP Integrity BL870c Server-Blade User Manual

Page 17: Checking general safety gathering necessary tools

4 Installation Preparation Steps

NOTE:

Preparation for the installation of any equipment in a Telco facility is dictated by the

Telcordia Technologies GR-1275-CORE Central Office Environment Installation/Removal Generic

Requirements. It defines everything from the Method of Procedure (MOP) that Telco customers

require to the crimping methods that are acceptable to how to secure cables. For example, tie

wraps are not permitted, all cables must be tied in place using waxed string.

Checking General Safety

Before installing a cabinet or connecting input power cables, verify that:

•

No input power cables that are routed, installed, and connected are energized.

•

Wiring complies with local practices or local electrical safety codes that apply to the particular

installation site.

•

The -48V DC input power cables are insulated, stranded copper and are the appropriate size

for each type of cabinet or connection. There should be no more than a 1.0-V drop throughout

the combined length of the cables, from the installation site power source to the lugs that fasten

to the cabinets.

•

The ground cables are stranded copper and are the appropriate size for each type of cabinet.

•

The installation site safety grounding system used to connect the cabinets minimizes development

of electrical potential within and between cabinets, which could create a shock hazard from

lightning or fault currents.

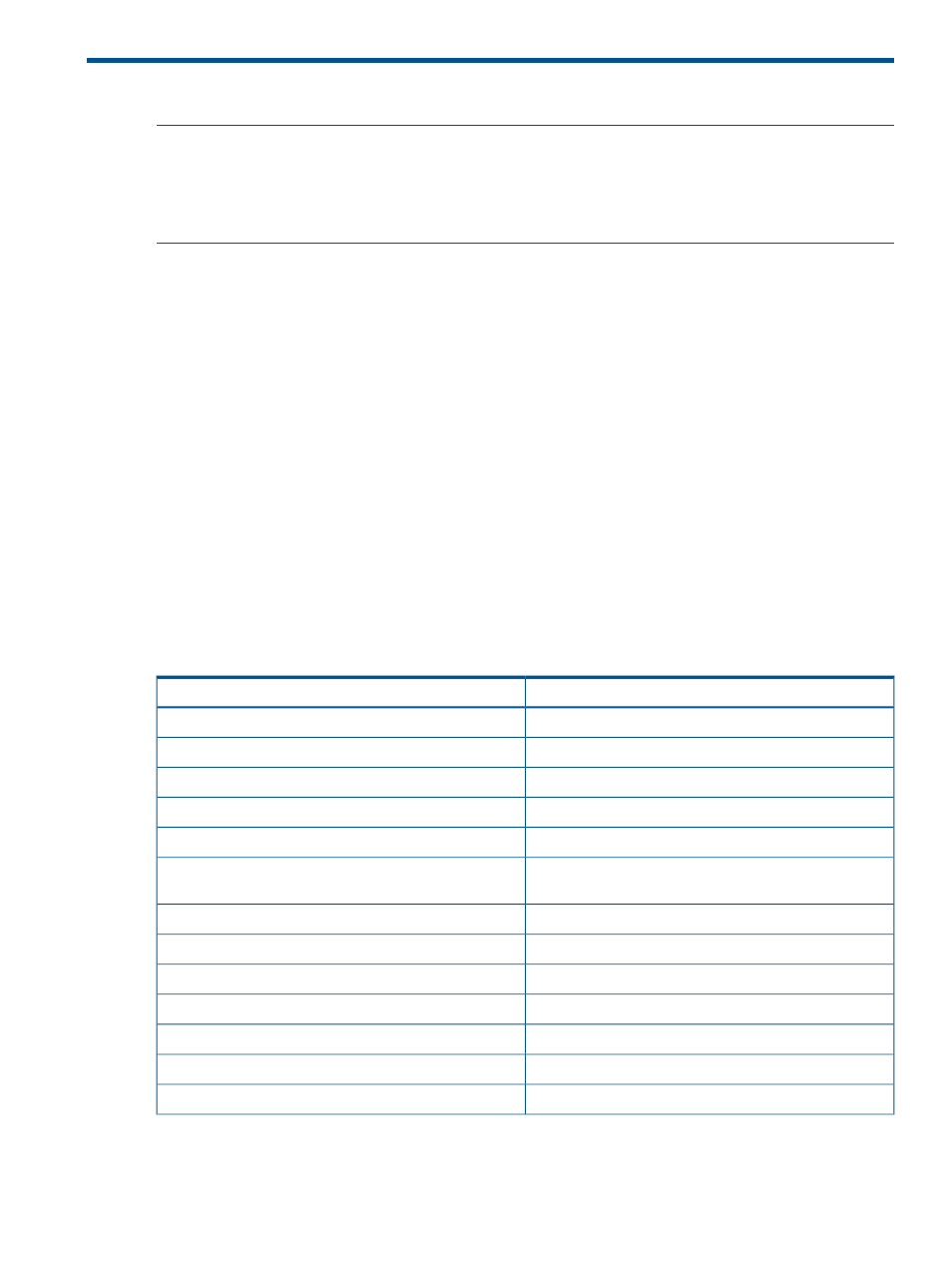

Gathering Necessary Tools

You need these tools for installing the cabinets and connecting the cables:

Purpose

Tool

Move racks from shipping pallet to final position.

Caster kit for seismic racks

Protect components against electrostatic discharge

ESD protection kit

Move shipping pallets to installation area

Heavy-freight-handling equipment

Prevent eye injury from flying particles

Safety glasses

Cut cable ties, banding straps, tape, and plastic wrapping

Cutters and utility knife

Reach to the top of the cabinet to install labels or ground

connection

Ladder or step stool

See components within cabinet

Flashlight

Label cables

Pens or pencils

Tap anchor bolts into the concrete floor

Three-pound single-jack hammer

Ensure all system cabinets are level

Level (minimum 24 inches long)

Loosen and tighten Phillips screws

#2 Phillips screwdriver

Remove kickplates and side panels on seismic racks

Large flat-blade screwdriver

Loosen and tighten Torx screws

T-10, T-15, T20, T-25, and T-30 Torx driver

Checking General Safety

17