The measuring head assembly, Dew point measurement, Starting / stopping the pump – ROTRONIC MBW 373 User Manual

Page 11

7

this is not required and nothing is wrong with leaving the Units menu (or any other menu) on

the screen.

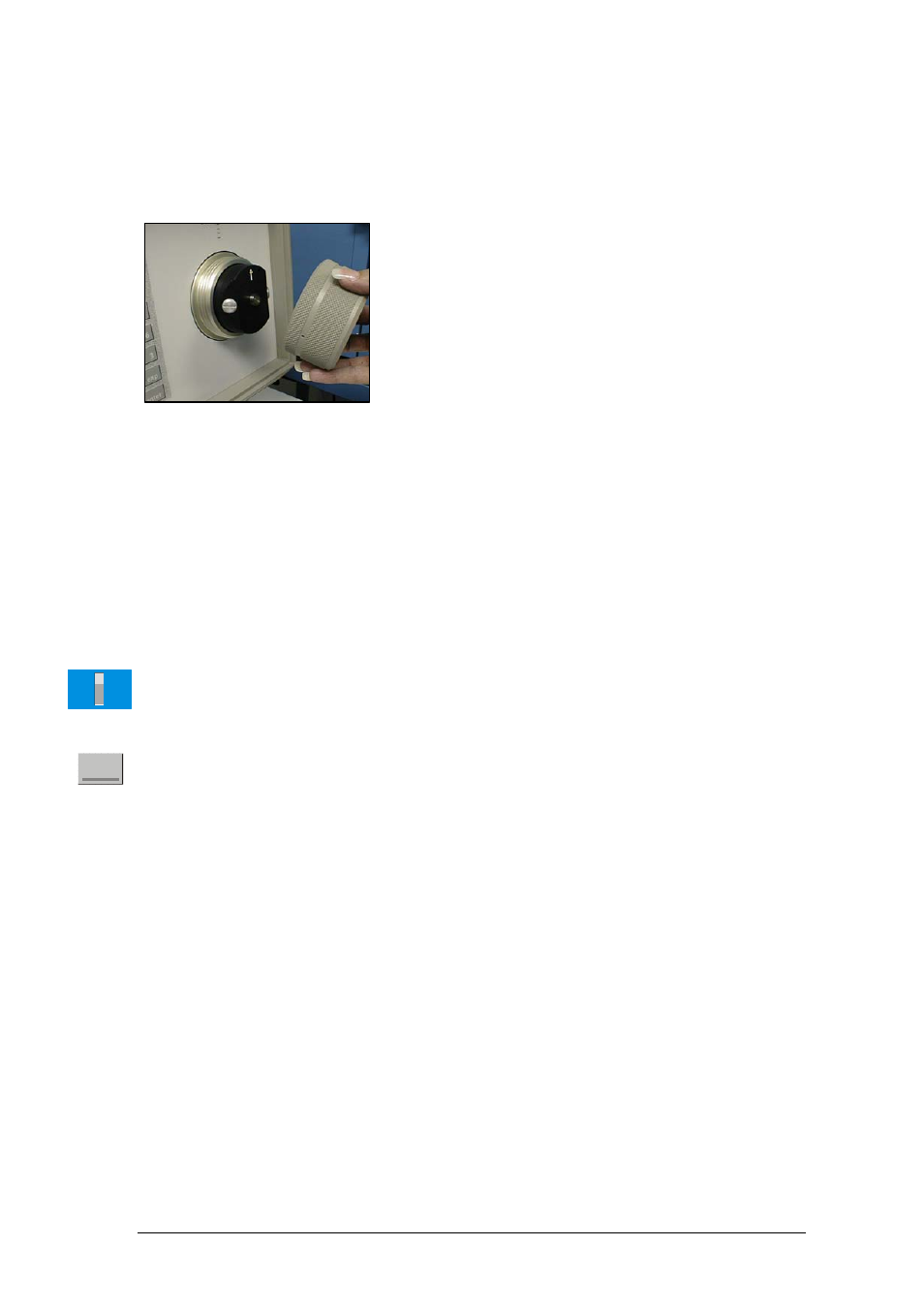

The Measuring Head Assembly

The heart of the 373 Dew Point Mirror instrument is the

measuring head assembly. It is designed to be highly

sensitive and accurate, yet rugged and easily accessible for

periodic mirror cleaning. Although not required prior to initial

operation, you may wish to familiarize yourself with the

location and accessibility of the mirror and the other optical

components within this assembly.

For further discussion of the measuring head, and the mirror

cleaning procedure, refer to Mirror Cleaning on page 43.

Dew Point Measurement

When you power the 373 on, it begins in an idle state. In this state, it measures and displays

temperature, pressure, and flow transducers, but does not yet provide any meaningful humidity

related data. In order to provide humidity data (dew point, frost point, %RH, etc.), the Dew/Frost

Control mode must be enabled and gas must be flowing across the mirror. If %RH is desired,

note also that an external temperature probe must be connected. For external temperature

probe use, see External Temperature on page 23.

Starting / Stopping the Pump

Some gas flow is required over the mirror when measuring the dew or frost point temperature.

The nominal gas flow desired is approximately 20 to 60 liters/hour (0.2 to 1.0 liters/minute). If

your 373 is equipped with an internal gas pump, you can use it to provide the necessary gas

flow. If not, then you may need to provide for gas flow in some manner.

Use the Pump key on the bottom row of the touch screen to toggle the pump on/off. The Flow

Rate indicator on the status line should indicate that gas is flowing. The actual rate of flow is not

critical, but is best when within the limits previously mentioned. The gas flow may be adjusted

with an external valve, or by changing the pump control parameters. See Pump Control on page

17.

Notes:

1.

On the L and LX models, the gas inlet and outlet connections are generally capped for

transportation, or during periods of non-use, in order to keep the gas path dry. You’ll

need to remove these caps to allow for gas flow.

2.

The L and LX models are generally not equipped with a gas pump and therefore some

alternate means of providing gas flow will be required for normal measurements.

(Although the measurements will most likely be inaccurate, operating without flow does

not harm the system. Therefore, you may continue on in this section even if your

system is not equipped with a pump.)

Pump

Flow Rate

60

30

0