NORD Drivesystems BU0210 User Manual

Page 51

7 Troubleshooting

BU 0210 GB

Subject to technical amendments

51

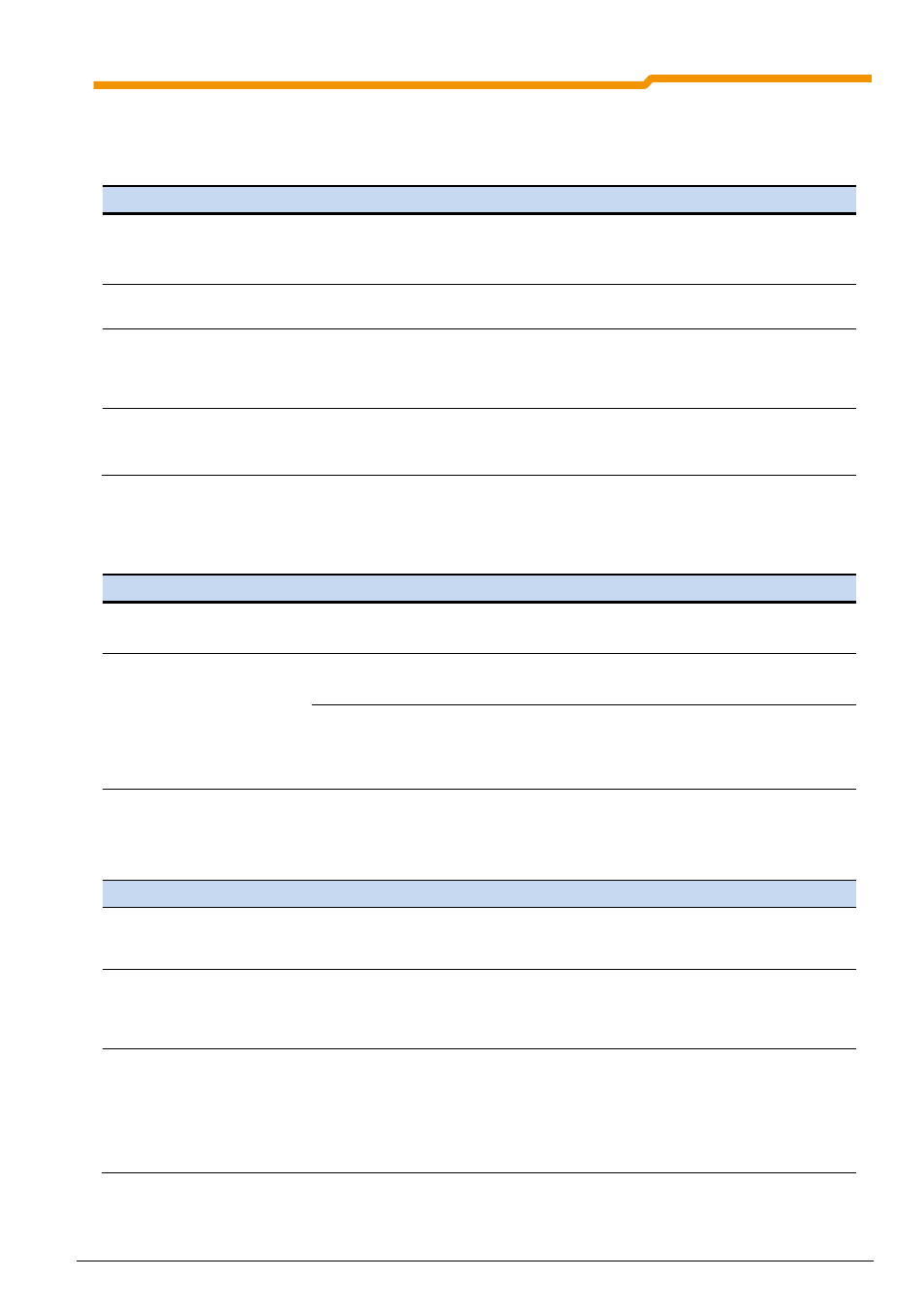

7.2.2

General causes of faults

Symptom

Additional test

Possible cause

Position exceeded

Position control P amplification considerably too large

Speed control (servo mode) not optimally adjusted (Set

I-amp. to approx. 3%/ms, P-amp. to approx. 120%)

Drive oscillates at the

position

Position control P amplification considerably too large

Drive moves in the wrong

direction (away from the

setpoint position)

The direction of rotation of the absolute encoder does

not match the direction of rotation of the motor =>

parameterise an negative value for the speed ratio

(P607)

Drive unit sags away after

enabling is removed (lifting

gear)

Setpoint delay missing (control parameter);

for servo mode = "OFF" the control must be locked

immediately by the event "End Point Reached"

7.2.3

Special sources of faults for position control with incremental encoders

Symptom

Additional test

Possible cause

Position drifts away

Interference pulse in the encoder cable

No reproducible precision

when approaching the

position,

even at low speeds

(n < 1000 1/min)

Interference pulse in the encoder cable

only at high speeds

(n > 1000 1/min)

Pulse number in combination with the encoder

cable length / Cable type too large (Pulse frequency

too large)

Loose encoder / Installation fault

7.2.4

Special sources of faults for position control with absolute encoders

Symptom

Additional test

Possible cause

Actual position value always

runs to the same value and

then no longer changes

Encoder

connection

faulty

Position not always found at

the same place, axis

sometimes jumps

backwards and forwards.

Mechanical unevenness?

Axis stiff, axis jams etc.

Loose encoder / Installation fault

if the position value does not

match the encoder rotation

or jumps

Check absolute encoder

(remove, set parameter speed

and reduction ratio to 1, rotate

encoder manually: the displayed

position must match the rotations

of the encoder)

Encoder

defective