3 specifying the setpoint – NORD Drivesystems BU0210 User Manual

Page 23

3 Function description

BU 0210 GB

Subject to technical amendments

23

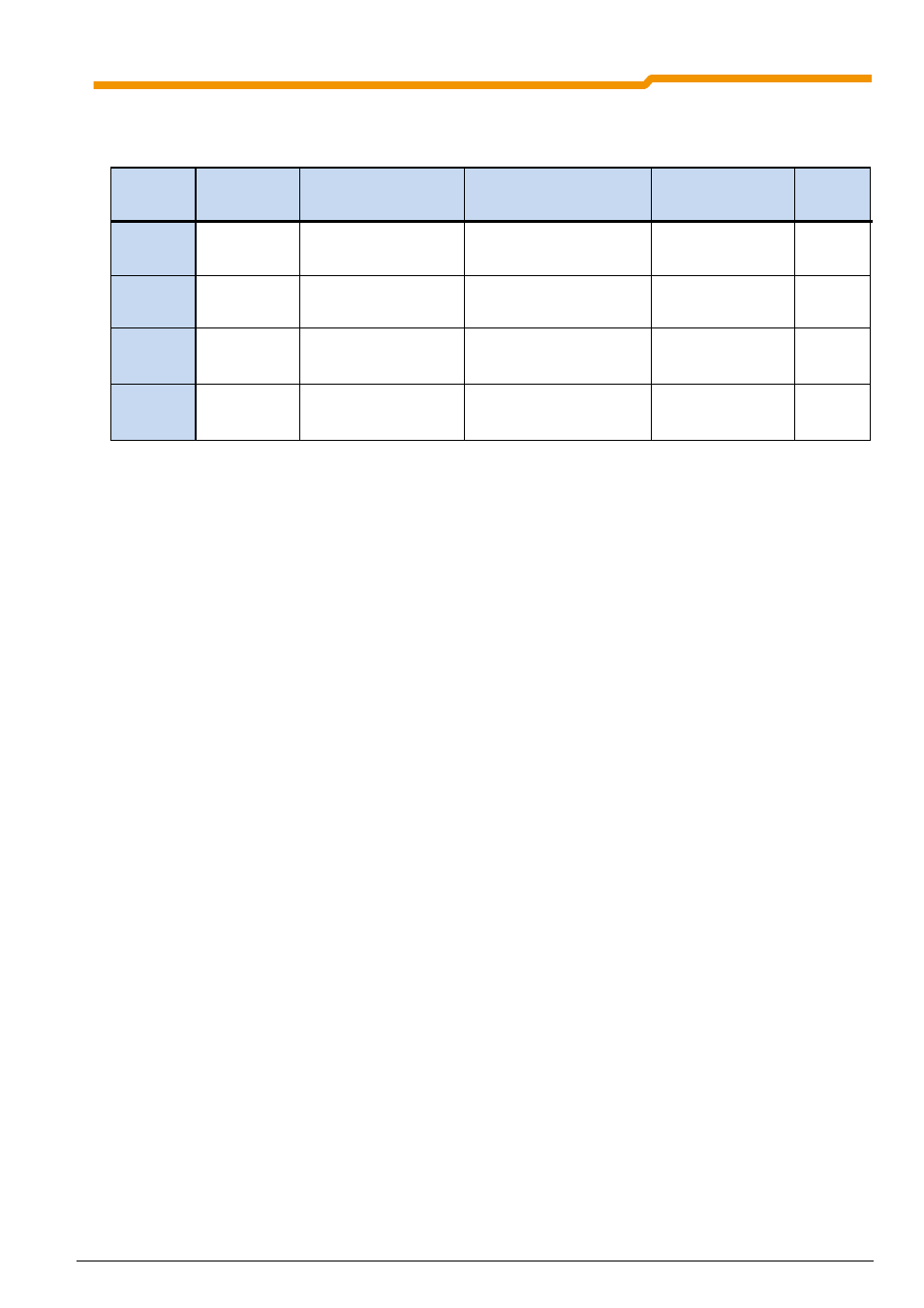

Overview of incremental and absolute encoder parameter settings

Number of

rotary encoder

rotations

P604 Encoder Type

P605 CANopen absolute

encoder resolution

P615 Maximum

Position

Reference

Run

Single-turn -

Absolute

Encoder

1

5 = CANopen

Optimised path

Array [01] = 0

Array [02] = Pulse number

0 No

Multi-turn -

Absolute

Encoder

≥ 1

5 = CANopen optimised

path

Array [01] = Number

Array [02] = Pulse number

0.5 * Total rotations

No

Incremental

Rotary

Encoder

1

3 = Increment, absolute

4 = Increment, absolute

with saving

-

0 Yes

Incremental

Rotary

Encoder

> 1

3 = Increment, absolute

4 = Increment, absolute

with saving

-

0.5 * Total rotations

Yes

Array [01] = Multi-turn resolution - number of possible rotary encoder rotations

Array [02] = Single-turn resolution - resolution per rotation of rotary encoder

NOTE

A multi-turn encoder can also be used as a single-turn absolute encoder. For this, the setting

of the parameter P605 "Absolute Encoder" in Array [01] for multi-turn resolution must be

parameterised to 0 (See table below under P605 for the single-turn absolute encoder)

3.3 Specifying the setpoint

Three different procedures are available for specifying the setpoint. The specification of the setpoint can be

made via:

digital inputs or Bus IO In Bits as absolute position by means of the position array

digital inputs or Bus IO In Bits as relative position by means of the position increment array

Bus setpoint value

For the specification of the setpoint value it does not matter how the actual position is obtained. Absolute,

relative and bus setpoint values can be specified, regardless of whether an absolute encoder or incremental

encoder are used for the feedback of the number of rotations.

3.3.1

Position array – absolute setpoint position via digital inputs or BUS I/O In Bits

In parameter P610 "Setpoint Mode" up to 15 positions can be selected via Function 0 = "Position Array", using

the digital inputs 1-4 of the inverter or the Bus IO In Bits. If the I/O-extension is used, there are additionally up

to 4 digital inputs, which are also interpreted as Bus IO In Bits.

The position numbers result from the binary value. A position setpoint value can be parameterised for each

position number. The position setpoint value can either be entered via a control panel (Control Technology Unit

or Parameter Technology Unit) or with a PC by means of the "NORD CON" parameterisation software (read

out and adopt current position), or via "Teach-in" by travelling to the positions.

With the setting [62] "Sync for Position Array Pointer" for the digital inputs or BUS I/O In Bits it is possible to

control the start of travel to the setpoint position. If one of the inputs or bus IO In bits is parameterised to [62]

"Sync for Position Array Pointer", by means of further digital inputs or Bus I/O In Bits, the position or the

position array can be preselected as binary code. The position value is adopted as the setpoint position as

soon as the input "Sync for Position Array Pointer" is set to "1".