Dwyer DPM User Manual

Page 37

Particulate Monitoring Systems

Installation & Operating Manual

Document No. 210-1003-M

Page 30

©2007

Alarm Relay

An alarm output relay can be activated if any self checks are unsuccessful. The alarm relay will

remain activated until a subsequent self check is performed successfully, or power to the control unit

is disconnected. Alarm relay #1 will be activated in the event of a self check failure by default. Alarm

output relays may be configured to operate in normal or fail-safe modes.

4-20mA Output

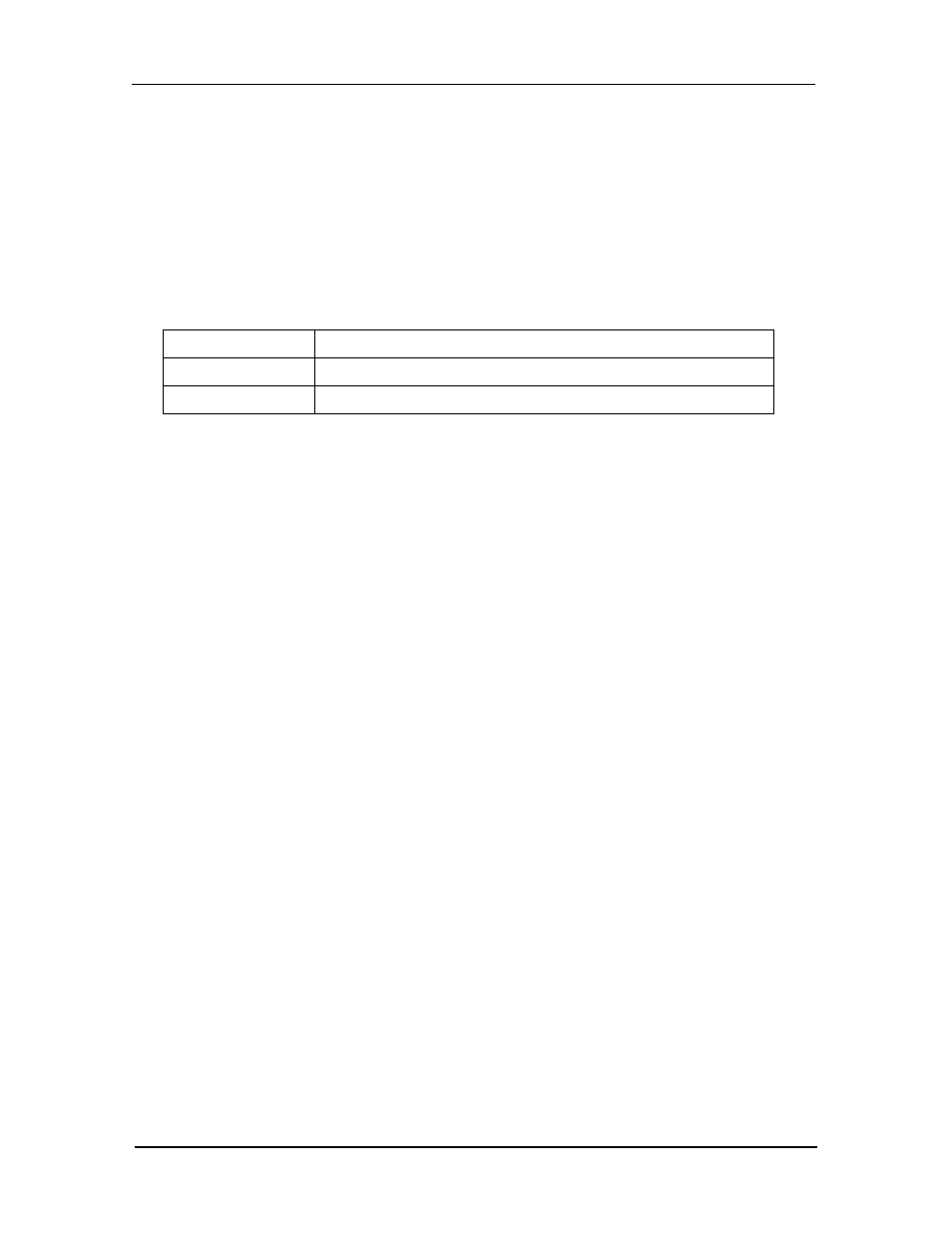

The 4-20mA output will be driven to non-standard levels to indicate self check status as listed below:

mA Output

Indication

3.8mA

Zero or span check in process, sensor is disconnected

3.6mA

A self check error has occurred

Serial or Ethernet Communication Network

All information regarding status, control and setup of the self check subsystem is accessible as

register data through the control unit’s communication network. See the Modbus® register map at the

end of this document for a complete detailed listing of registers data available.

8.8 Particulate Alarming During Self Checks

All particulate alarms are put in a suspend mode while a self check is being performed. When a self

check is completed, all particulate alarms will resume normal operation.

8.9 Self check Recording

EPA MACT regulations require that plants maintain a record of all self checks performed. To reduce

the number of plant personnel required to generate these records, the control unit provides two

methods suitable for automated record generation.

4-20mA Output

The 4-20mA output will be driven to specific, non-standard levels to indicate that self checks are

being performed and if any self check has failed. A PLC may be easily configured to monitor for

these specific, non-standard, mA levels and transmit status information to a central plant information

network for record storage.

Serial or Ethernet Communication Network

The overall status of each self check, as well as the results of the most recent self checks performed,

are accessible through the Modbus® network port. This information may be monitored and logged

with a remote PC running SCADA application software. Optional FilterWare Visualization and

Reporting software is available to monitor all of the control units self check information and

automatically generate MACT compliant self check reports.