Dwyer DPM User Manual

Page 27

Particulate Monitoring Systems

Installation & Operating Manual

Document No. 210-1003-M

Page 20

©2007

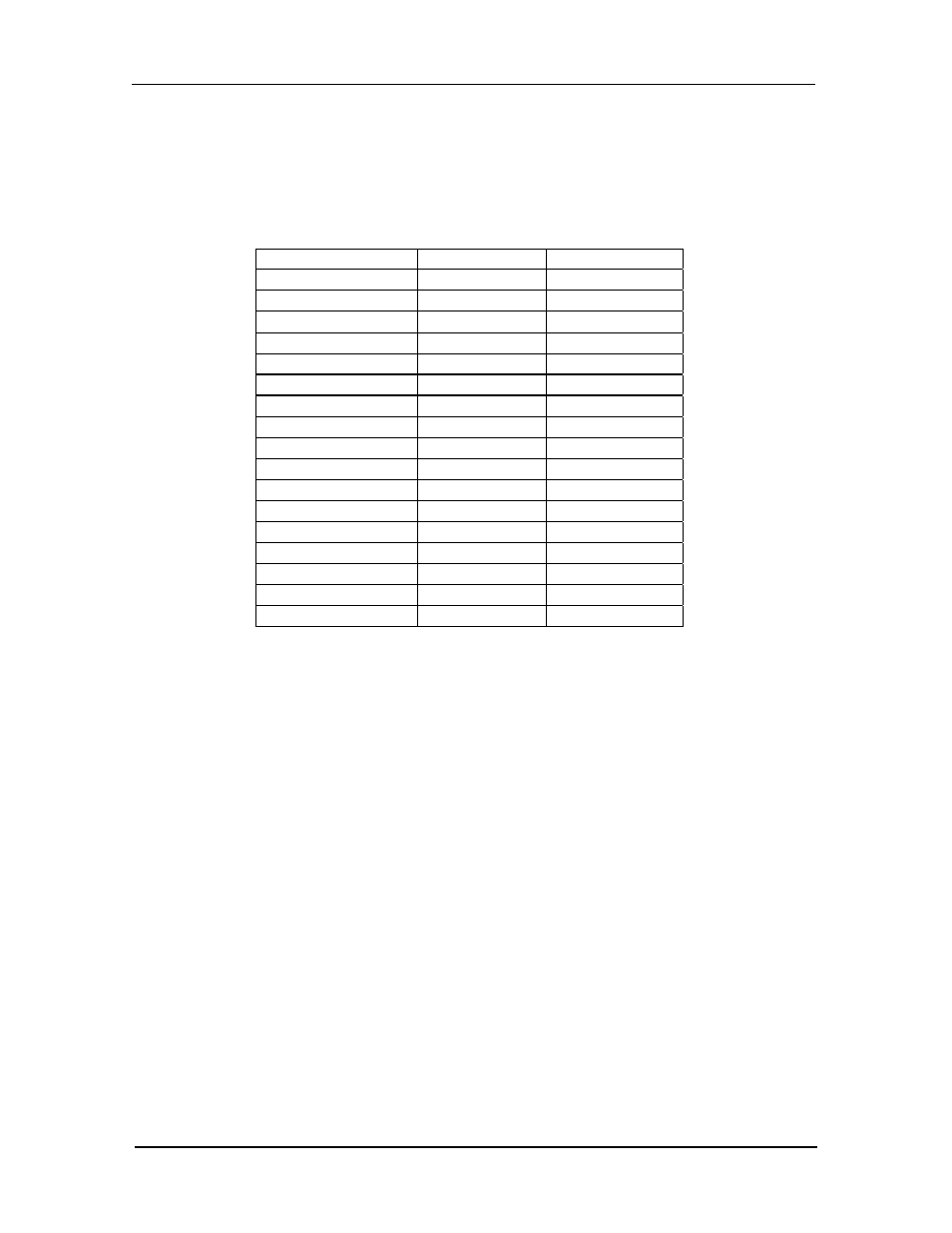

Example #2: See Menu #2 for details.

Where: 4-20mA Output Minimum Scale = 0.5pA

4-20mA Output Span = 500pA

Number_Of_Decades = Log (500 / 0.5) = 3

4-20mA Output

Y

pA

4 0.00

0.5

5 0.19

0.8

6 0.38

1.2

7 0.56

1.8

8 0.75

2.8

9 0.94

4.3

10 1.13

6.7

11 1.31

10.3

12 1.50

15.8

13 1.69

24.3

14 1.88

37.5

15 2.06

57.7

16 2.25

88.9

17 2.44

136.9

18 2.63

210.8

19 2.81

324.7

20 3.00

500.0

6.7 Interpreting Particulate Readings for Fabric Filter Applications

Particulate flow is very dynamic in nature, thus the output signal is also usually very dynamic. This is

more often the case with fabric filter and dust collection exhaust monitoring applications where filter

emissions and filter cleaning systems can cause wide ranging variations in the particulate levels.

When monitoring downstream of fabric filter, it is often possible for the difference between baseline

readings and peak readings following cleaning cycles, to vary by a factor of 10 or even 100. This is

the reason for the logarithmic output (linear output is also easily selected using the keypad).

The logarithmic scale provides the ability to simultaneously monitor and resolve the baseline and

peak readings. It is not uncommon to have baseline readings of less than 10pA while at the same time

peak readings may be over a hundred or more.

Particulate levels listed below are typical for new or well maintained bag or cartridge filter dust

collection system. Many factors, other than generic bag wear may contribute to high particulate levels

including but not limited to: Improper filter installation, bad tube sheet seals, improper filter media

for process conditions, high differential pressure or a lack of a filter cake buildup.