Automatic self checks – Dwyer DPM User Manual

Page 33

Particulate Monitoring Systems

Installation & Operating Manual

Document No. 210-1003-M

Page 26

©2007

8. Automatic Self Checks

An optional self check subsystem is available to automatically verify calibration and proper operation

of the electronics, sensor and cable. Self checks can be performed while the system is online and

monitoring particulate. No external test equipment or operator intervention is required to activate or

complete the self check routines. Any errors detected by the self checks are reported through the

display, 4-20mA, relay and Modbus® outputs. The following automatic self checks are performed:

• Control Unit Hardware Check

• Control Unit Calibration (Zero and Span)

• Sensor Cable Check

• Particulate Sensor/Probe Check

The control unit zero and span self checks that are performed meet all requirements of the EPA

MACT Quality Assurance specifications. Self checks are automatically run every hour. A manual Self

Check may be activated anytime through the control unit keypad.

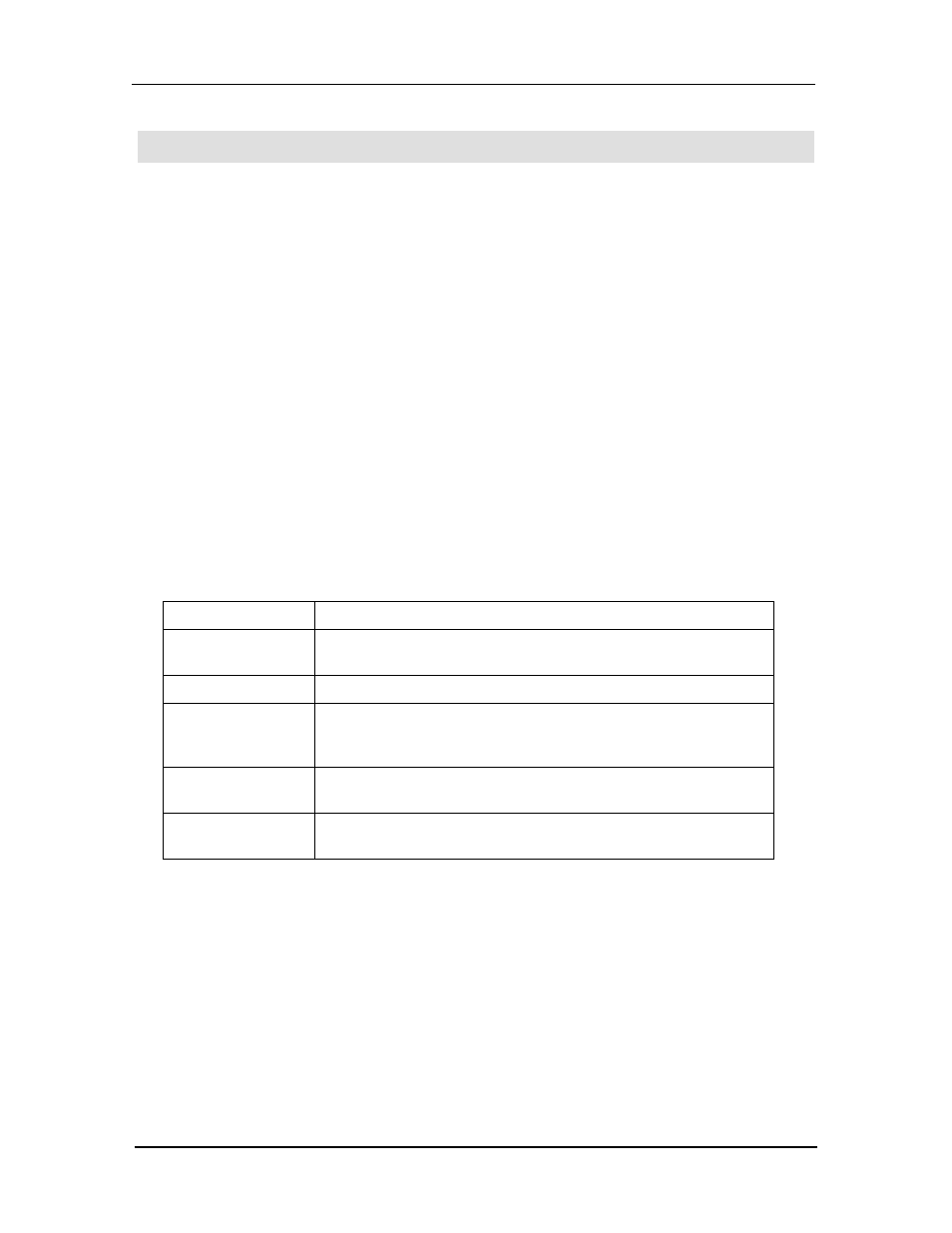

8.1 Control Unit Hardware Check

The Control Unit Hardware Check is an automatic check of all major electrical components in the

control unit. This check is automatically performed each time power is applied to the control unit.

Check Description

Watchdog Timer

Monitors all program tasks running in the microprocessor and

automatically resets the processor in the event of lock-up.

SRAM

Checks the integrity of the SRAM memory.

Non-Volatile

Memory

Checks the integrity of the Non-Volatile memory. The results of this

check produce a checksum value which is analyzed each time a non-

volatile memory write occurs.

Option Board

Checks for proper installation of Power Supply, RS-485 and Self

Check option boards.

Analog Converter

Calibration

Checks calibration of the 22 bit high resolution analog converter.