Control unit operation – Dwyer DPM User Manual

Page 19

Particulate Monitoring Systems

Installation & Operating Manual

Document No. 210-1003-M

Page 12

©2007

6. Control Unit Operation

6.1 User Interface Overview

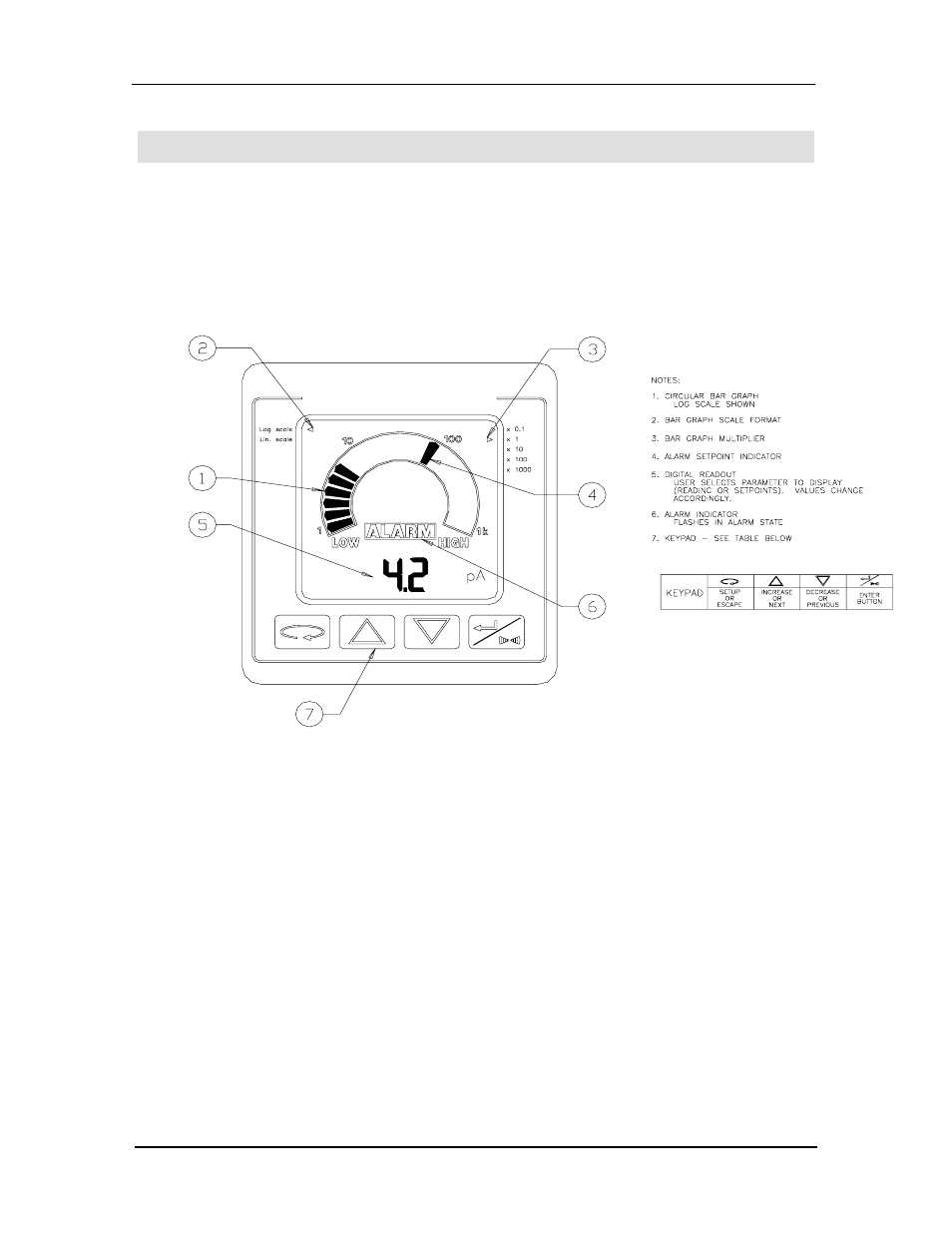

The following drawing shows the user interface consisting of a four-button keypad and an LCD

display. The LCD display has a scalable analog bar graph combined with a digital readout for ease in

interpreting the dynamic readings, which are typical with particulate flow.

Control Unit

The control unit has two alarm relays which are individually activated when the reading continuously

exceeds the alarm setpoint for the amount of time delay specified. Each is an SPST (FORM A) relay

contact output.

Alarm logic may be set to Normal or Fail-safe mode. In Normal mode, the alarm relay contact is open

under normal conditions and closes when the associated alarm is active. In Fail-safe mode, the alarm

relay contact is closed under normal conditions and opens when the associated alarm is active, or

when power to the control unit is removed.

When the reading exceeds the alarm setpoint, the alarm delay timer is started. As long as the reading

remains above the alarm setpoint, the alarm delay timer will continue timing. If the reading drops

below the alarm setpoint before the alarm delay timer expires, the alarm delay timer is reset. If the

reading remains above the alarm setpoint and the alarm delay timer expires, an alarm is activated and

the associated alarm relay contact will close (Normal logic) or open (Fail-safe logic).

If an alarm is activated and the reading drops below the alarm setpoint, the alarm is cleared and the

alarm delay timer is reset. As described above, alarms will clear automatically and no operator

acknowledgment is required.

Control units designed for powder flow applications include the ability to define a LOW alarm level

that will activate when the particulate reading falls BELOW the setpoint. See Menu 1 Setup details.