Easicool™ precision air conditioning, Ins ta lla tio n – Airedale EasiCool 6kW 64kW User Manual

Page 51

EasiCool™

Precision Air Conditioning

51

EasiCool Technical Manual 7525389 V1.1.0_02_2013

Ins

ta

lla

tio

n

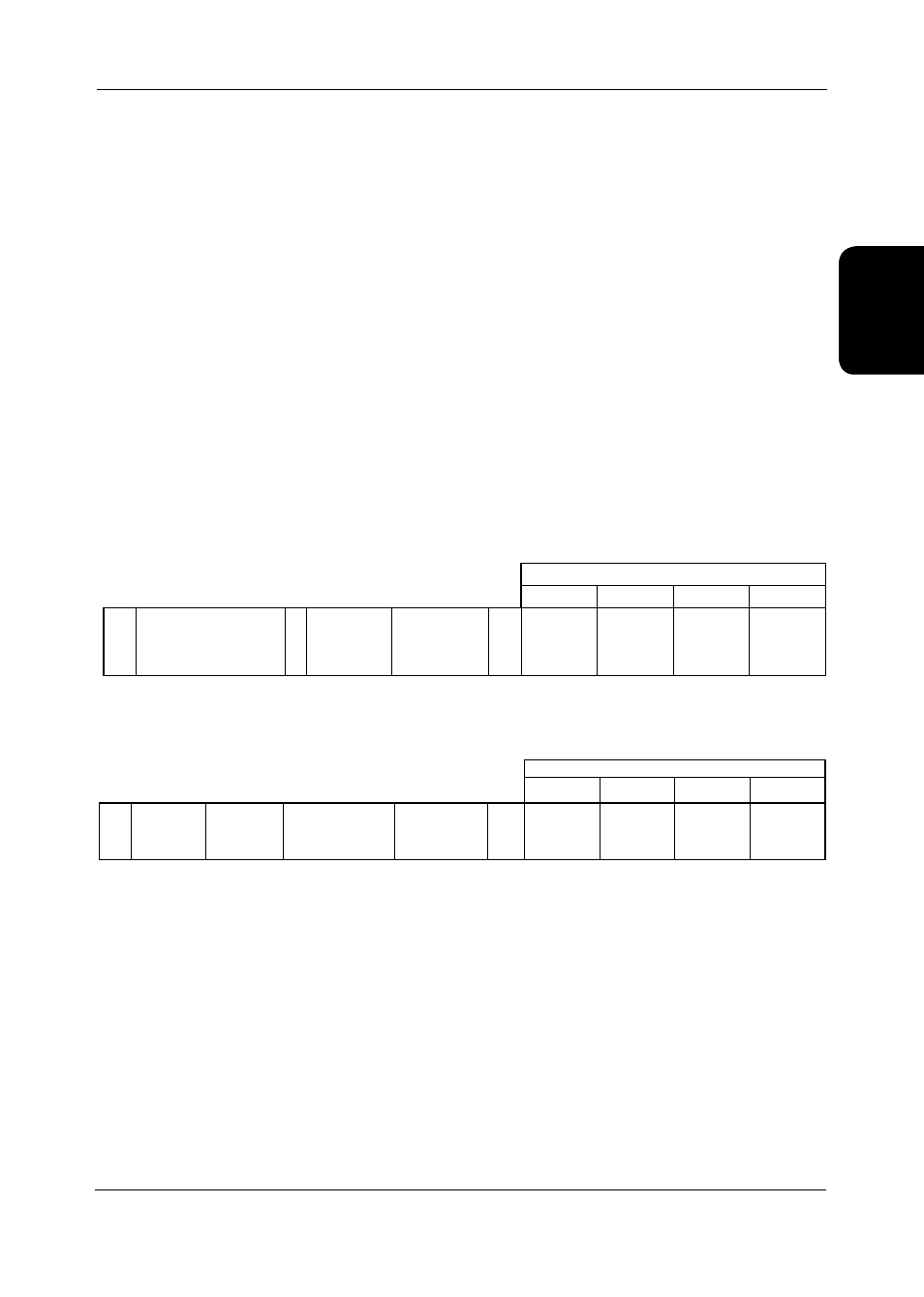

Ethylene Glycol Correction Factors - WX Models

For conditions outside those quoted, please refer to Airedale.

The Use of Glycol

Glycol is recommended when a supply water temperature of +5°C or below is required or when static water can be

exposed to freezing temperatures.

The presence of glycol in the system has a direct effect upon the Cooling Duty, the Design Flow Rate and the unit

Pressure Drop.

To approximate the effect of glycol on unit performance, the following correction factors when applied can be used as a

guide.

Where:

V

=

Corrected Flow Rate

THR = Equivalent Total Heat of Rejection (THR) (kW), refer to

Cooling Duties - WX Models

, (the change in THR values

as glycol concentration is increased is negligible.)

∆

T

= Temperature difference between Water/Glycol Inlet/Outlet (°C).

∆

P

= Maximum Water/ Glycol Pressure Drop for the indoor unit (kPa).

∆

Pw = Equivalent Water Pressure Drop for indoor unit (kPa), use the corrected flow rate

V

. Refer to

Waterside

Pressure Drop (kPa) - WX Models

.

Ethylene Glycol (Volume) / Freezing Point °C

10% / -4°C

20% / -9°C 30% / -15°C 40% / -23°C

V

Corrected Flow Rate

= THR / ∆T

Flow Rate

x by

0.240

0.250

0.250

0.260

∆

P

Corrected Pressure Drop = ∆Pw

Pressure Drop

1.041

1.083

1.133

1.200

Example:

V26WX2-EZ Condensing Entering / Leaving at 30°C/35°C, Based on ΔT of 5°C,

24°C/45% RH Ambient, 20% Ethylene Glycol

Ethylene Glycol (Volume) / Freezing Point °C

10% / -4°C

20% / -9°C

30% / -15°C 40% / -23°C

V

1.76 l/s

=

THR (35.2) / ∆T

(12 - 7 = 5∆T) =

7.04

x by

0.240

0.250

0.250

0.260

∆

P

157Pa

=

∆

Pw

145 kPa

1.041

1.083

1.133

1.200