Preparations for wiring 2.5, Figure 2-1, 1 wiring guidelines – West Control Solutions MRC 7000 Profiler Manual User Manual

Page 9: 1 installation considerations

9

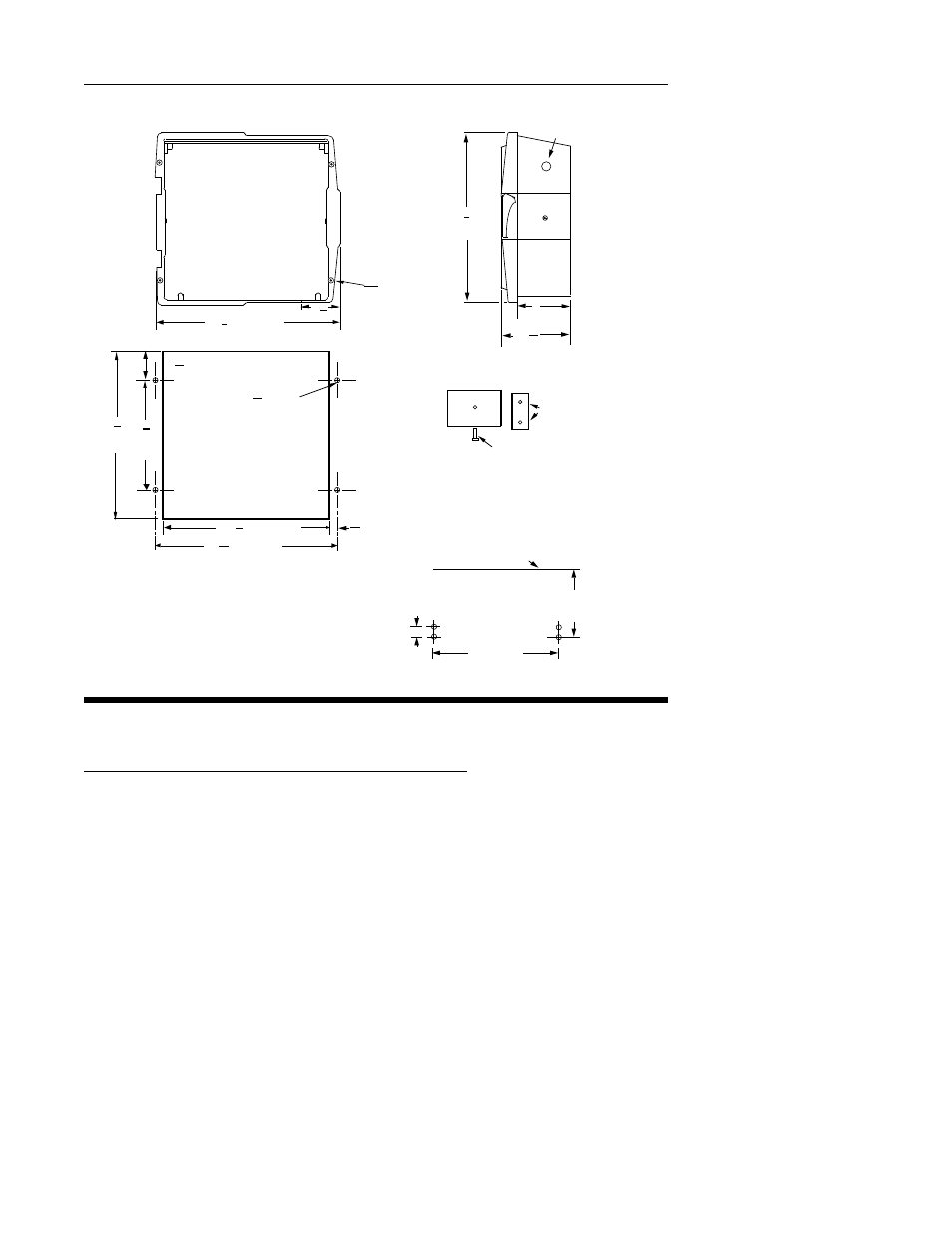

FIGURE 2-1

Preparations for Wiring 2.5

2.5.1 WIRING GUIDELINES

Electrical noise is a phenomenon typical of industrial environments. The following are guide-

lines that must be followed to minimize the effect of noise upon any instrumentation.

2.5.1.1 INSTALLATION CONSIDERATIONS

Listed below are some of the common sources of electrical noise in the industrial environ-

ment:

• Ignition Transformers

• Arc Welders

• Mechanical contact relay(s)

• Solenoids

Before using any instrument near the devices listed, the instructions below should be

followed:

1. If the instrument is to be mounted in the same panel as any of the listed devices,

separate them by the largest distance possible. For maximum electrical noise

reduction, the noise generating devices should be mounted in a separate

enclosure.

2. If possible, eliminate mechanical contact relay(s) and replace with solid state

relays. If a mechanical relay being powered by an instrument output device

cannot be replaced, a solid state relay can be interposed to isolate the instrument.

(Continued on next page)

320.7 mm)

(190.5 mm)

(342.5 mm)

( 354 mm)

7

32 (5.5 mm)

9

32 DIA.(7.1mm)

Panel cut-out for flush mounting

15 1

8

(384.2 mm)

2 1

2

(64 mm)

WIDTH OF COVER

4

11

16

(119.1 mm)

13 3

16

(335 mm)

EC1

EC3

EC2

4

PLACES

12

5

8

7 1

2

13

1

2

13 15

16

(65.9 mm)

219

32

Mounting Bracket (2)

Screw that mounts to case

Holes to mount

bracket to surface

14 11/16"

373mm

7 3/4"

196.9mm

2.5"

63.5mm

Holes should be sized to accommodate screw type

needed to fasten instrument. This is up to the installer.

Note: Surface Mount

Dimensions

Top edge of case

7/8" Dia hole for

wiring - 3 locations,

EC1, EC2, and EC3

3 3

4