KROHNE BATCHFLUX 5015 K EN User Manual

Page 51

Installation and operating instructions

51

BATCHFLUX

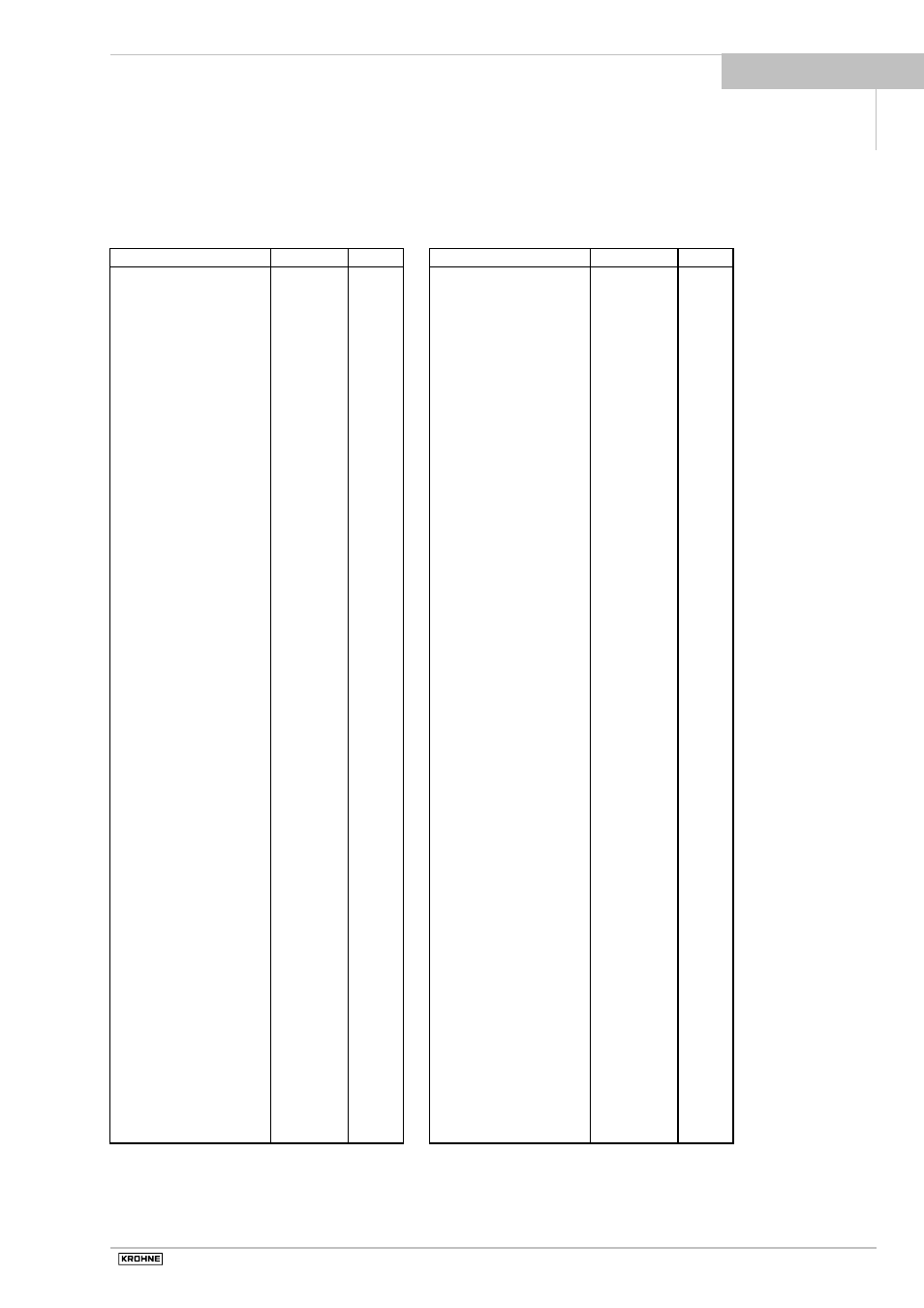

Keyword Section-No.

Fct-No.

N

Number format of display

5.4, 5.5

1.4

O

Operating pressure

10.5

Option = add-on equipment

= HHT 010

4.2, 6.1,

10.3-10.5 ,

Order numbers

9

Outputs

– connection diagrams

2.3

– characteristic

5.14

– setting

4.4

– I

5.6

1.5

– P

5.7

1.6

– S

5.8

1.7

Overflow display

5.5

1.4

P

P = pulse output

2.3.2, 4.4,

5.7

1.6

PC software

6.1

PCB =control electronics

PE = protective conductor

1.3.3, 2.1,

2.2

Power supply (= line voltage)

– connection

2.2, 10.5

– failure

4.5, 7.4

– frequency

2.2, 10.5

– power consumption

10.5

– voltage

2.2, 10.5

– changeover

8.2

Primary constant, see GKL

4.4, 5.11

3.2

Primary head

1.4.1

– installation

1.1 - 1.3

– installation dimensions

1.3.1, 10.6

Printed circuit boards, see

PCB

8.9

Process temperature

1.1, 10.5

Program organization

4.1

Programming area, entry into

4.1 - 4.3

Programming = input

4.1 - 4.3

Protective rings

1.3.1

Pulse duration = pulse width

4.4, 5.7

1.6

Pulse output P / pulse width

4.4, 5.7

1.6

Pulses per unit volume/time

4.4, 5.7

1.6

Q

Q = flowrate

4.4 + 5.1

1.1, 3.2

Q100% = full-scale range

4.4 + 5.1

1.1, 3.2

R

R = reverse flow

4.4, 5.13

1.4 - 1.7

Range setting

4.4, 5.1

3.1.1,

3.1.2

Removal of

– control electronics

8.3

– device (total)

1.4.2, 8.2

Reset totalizer

4.6

Return to

– functions column

4.1 - 4-3

– main menu column

4.1 - 4.3

– measuring mode

4.1 - 4.3

– submenu column

4.1 - 4.3

Reverse flow (R)

4.4, 5.13

1.4 - 1.7

RS 232 adapter

6.1

Keyword Section-No.

Fct-No.

S

S = status output

2.3.2, 4.4, 5.7

1.7

Safety conductor PE

1.2.3, 2.2

Scope of supply

1.3

Signalling cable A

1.3.4, 10.4

Signal converter IFC 015

– connection, power

2.2

– connection, HHT 010

4.2, 8.9

– operator control

4.1 - 4.3

– spare parts

9

– error limits

10.2

– functional checks

7.1 - 7.3,

– technical data

10.4

SMU = low-flow cutoff

4.4, 5.3

1.3

Software 6.1

Special function = Option

6.1, 10.3-10.5

Status indication output

5.8

Status output S

2.3, 4.4, 5.7

1.7

Start-up 3

Straight outlet run

1.1, 1.2

Straight inlet run

1.1, 1.2

Storage 1.1,

Standards

– ANSI . . .

1.3, 10.3,

10.4,

10.6-10.8

– DIN . . .

1.2 10.3,10.4,

10.6-10.8

– EN . .

10.4

– EMC

page 4

– IEC . . .

1.1,1.3.3,

10.3-10.5,

10.9

– VDE . . .

1.3.3, 2.1,

2.1,

10.4

Submenu column

4.1 to 4.3

T

T = time constant

5.2

1.2

Technical data

– measuring section / liners

10.3

– dimensions + weights

10.7, 10.8

– error limits

10.2

– limits for

liners

10.6

– signal converter IFC 015 K

10.2, 10.4

– primary head

10.5

Temperatures

– process product

10.3, 10.4, 10.6

– ambient

10.2 - 10.4

Tests, see functional checks

7.1, 7.2

Time constant (T)

5.2

1.2

Torques 1.3,

1.4.2

Totalizer (internal electronic)

5.7

1.6

Transport 1.1.1

U

Unit

– display

4.4, 5.4

1.4

– flow

4.4, 5.1

1.1

– pulse output

4.4, 5.7

1.6

User-definable unit

4.4, 5.12

3.5

V

v = flow velocity

4.4 + 5.1

3.2

Volumentric unit

5.12

3.5

Z

Zero check (adjustment)

7.1

3.3

E