KROHNE BATCHFLUX 5015 K EN User Manual

Page 5

Installation and operating instructions

5

BATCHFLUX

Functional description

BATCHFLUX IFM 5015 K

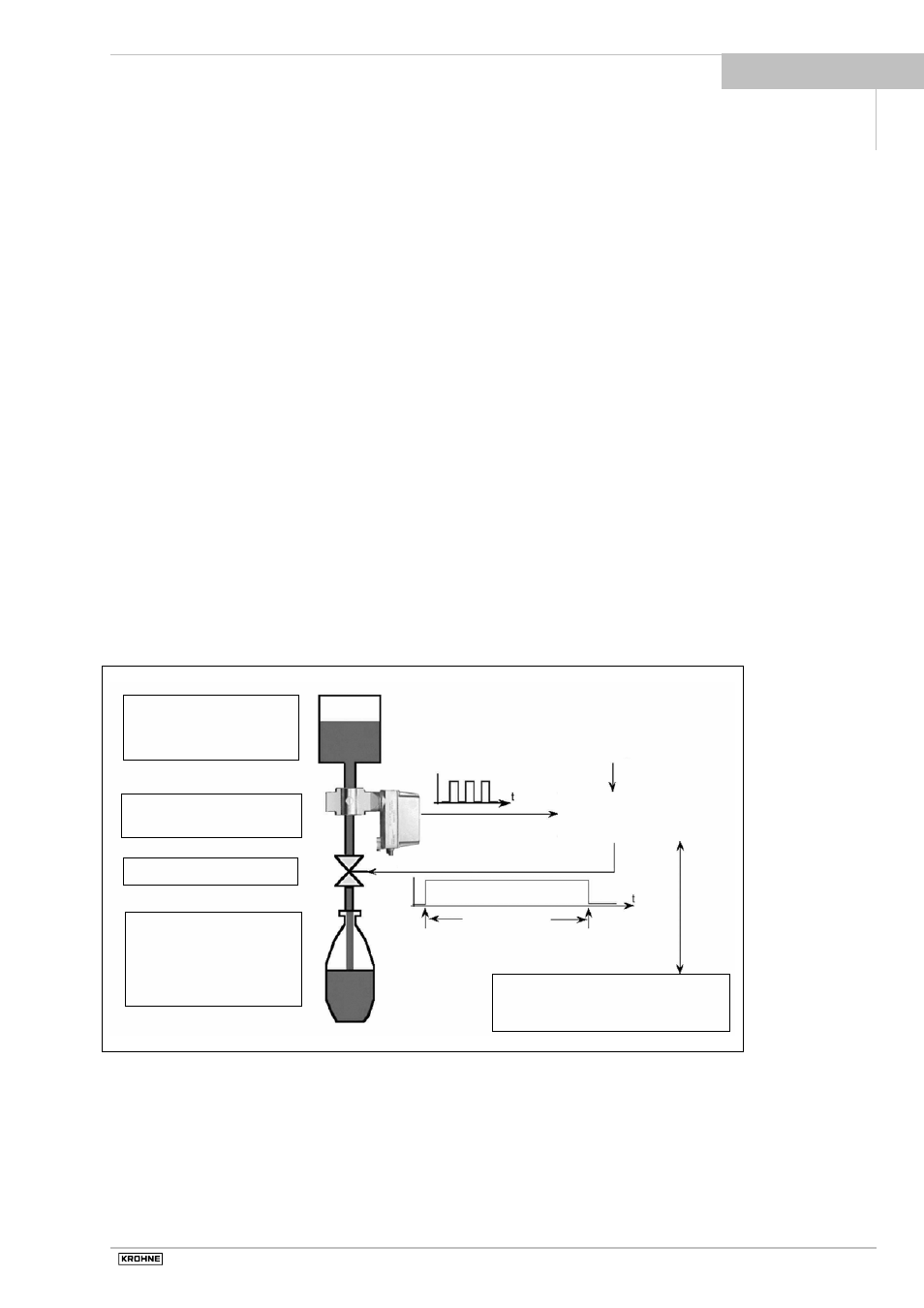

The volume to be filled into the container is

measured “in line“ by means of the

electromagnetic flowmetering system. The

batch controller closes the filling valve once

the preset filling volume has been reached.

It is always the preset target volume that is

filled into the container.

The signal converter converts the measured

flowrate signal into volume pulses that are

intelligible to the batch controller. For a filling

volume of 1000 ml, for example, this could

be 10 pulses per ml; in other words, the

batch controller switches the valve off after

1000 pulses have been received.

The influence of valve closing times and

other dynamic factors can be corrected by

the adaptive corrector of the batch controller.

The use of state-of-the-art microprocessor

electronics and the high-speed analog/digital

converter also enables changes in the

flowrate to be sensed precisely. This

technology ensures high reproducibility and

long-term stability.

Feed tank

(pressurized if liquid

contains CO

2

)

Flowmeter

BATCHFLUX

Valve

Container

bottle, tin, keg, paper or

plastic container

(pressurized if liquid

contains CO

2

)

Start command

when container is ready

for filling

e.g. 10 pulses per ml

pulses per

volumes

valve control signal

on

off

filling time t

F

open

valve

close

valve

External communication

(preselection,

measuring error correction)