KROHNE ALTOFLUX 2W IFM 4042K EN User Manual

Page 6

Section 1.3

Part A Installation and Start-up

ALTOFLUX 2W

02/2001

6

1.3

Installation location

•

Temperatures

Refer to Section 5.6 “Limits“ for operating pressure and vacuum load based on flange

standards and type of tube liner.

Ambient temperature

Process temperature

Standard

-25 to +60 °C

-13 to +140 °F

-25 to

≤

+ 60 °C

-13 to

≤

+140 °F

-25 to +40 °C

-13 to +104 °F

-25 to

≤

+140 °C

-25 to

≤

+284 °F

EEx

-25 to +60 °C

-13 to +140 °F

-25 to

≤

+ 60 °C

-13 to

≤

+140 °F

-25 to +40 °C

-13 to +104 °F

-25 to

≤

+140 °C

-25 to

≤

+284 °F

Storage and handling

-25 to +60 °C

-13 to +140 °F

•

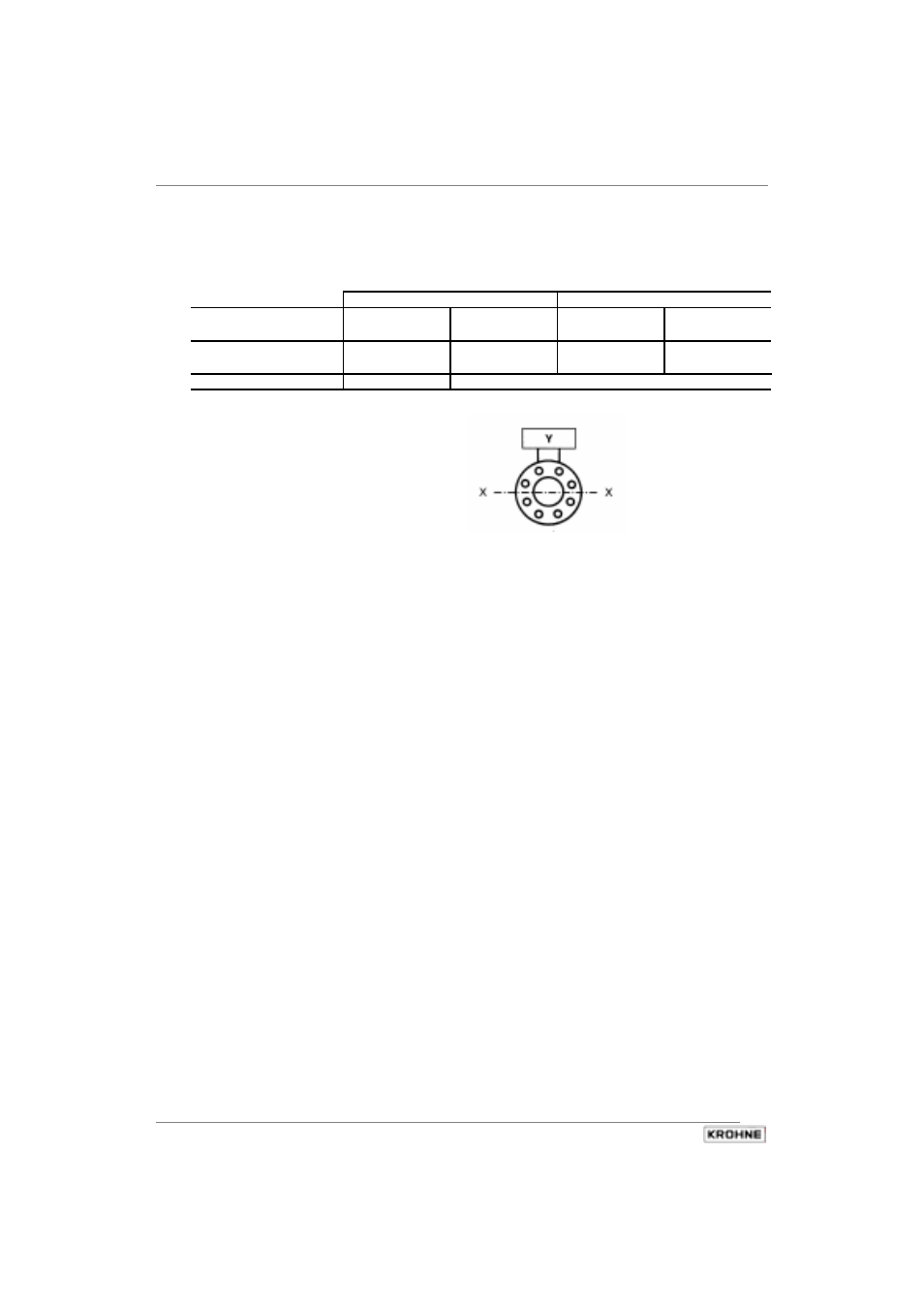

Location and position as required,

but in a horizontal pipe run

electrode axis

X – • – • – • – X

should be approximately horizontal.

Y Signal converter housing

•

Measuring tube must be completely filled at all times.

•

Direction of flow is arbitrary: arrow on flowmeter can normally be ignored.

For exceptions, refer to Sect. 3.2 “Factory settings” in the Installation and Operating

Instructions for the signal converter.

•

Stud bolts and nuts: to install, make sure there is sufficient room next to the pipe flanges.

•

Vibration: support pipeline on both sides of flowmeter. Level of vibration in conformity with

IEC 068-2-34: below 2.2g for flowmeters in the 20-150 Hz frequency range.

•

Do not expose to direct sunlight: fit a sunshade if necessary, not included with flowmeter,

to be provided by customer.

•

Avoid strong electromagnetic fields in vicinity of flowmeter.

•

Inlet run 5 × DN and outlet run 2 × DN, straight pipeline,

measured from electrode axis (DN = meter size)

•

Vortex and corkscrew flow: increase length of inlet and outlet runs or

install flow conditioners.

•

Mixing different process liquids: install flowmeter upstream of the mixing point or at an

adequate distance downstream (min. 30 × DN), otherwise display may be unsteady.

•

Plastic pipelines and internally coated metal pipelines: grounding rings required,

refer to Sect. 1.7 “Grounding“.

•

Insulated pipeline: do not insulate flowmeter.

•

Zero setting: not necessary. To check, it should be possible to set “zero“ flow velocity

when the measuring tube is completely filled. Shutoff valves should therefore be provided,

either downstream of the flowmeter or upstream and downstream of the flowmeter.

•

Electrical connection to VDE 0100 “Regulations governing heavy-current installations

with line voltages up to 1000 V” or equivalent national regulations.

•

Hazardous areas: subject to special regulations,

refer to special ‘EEx’ information (texts with grey background).