Technical data – KROHNE OPTITEMP TRA-TCA Plus EN User Manual

Page 46

7

TECHNICAL DATA

46

OPTITEMP TRA/TCA PLUS

www.krohne.com

01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

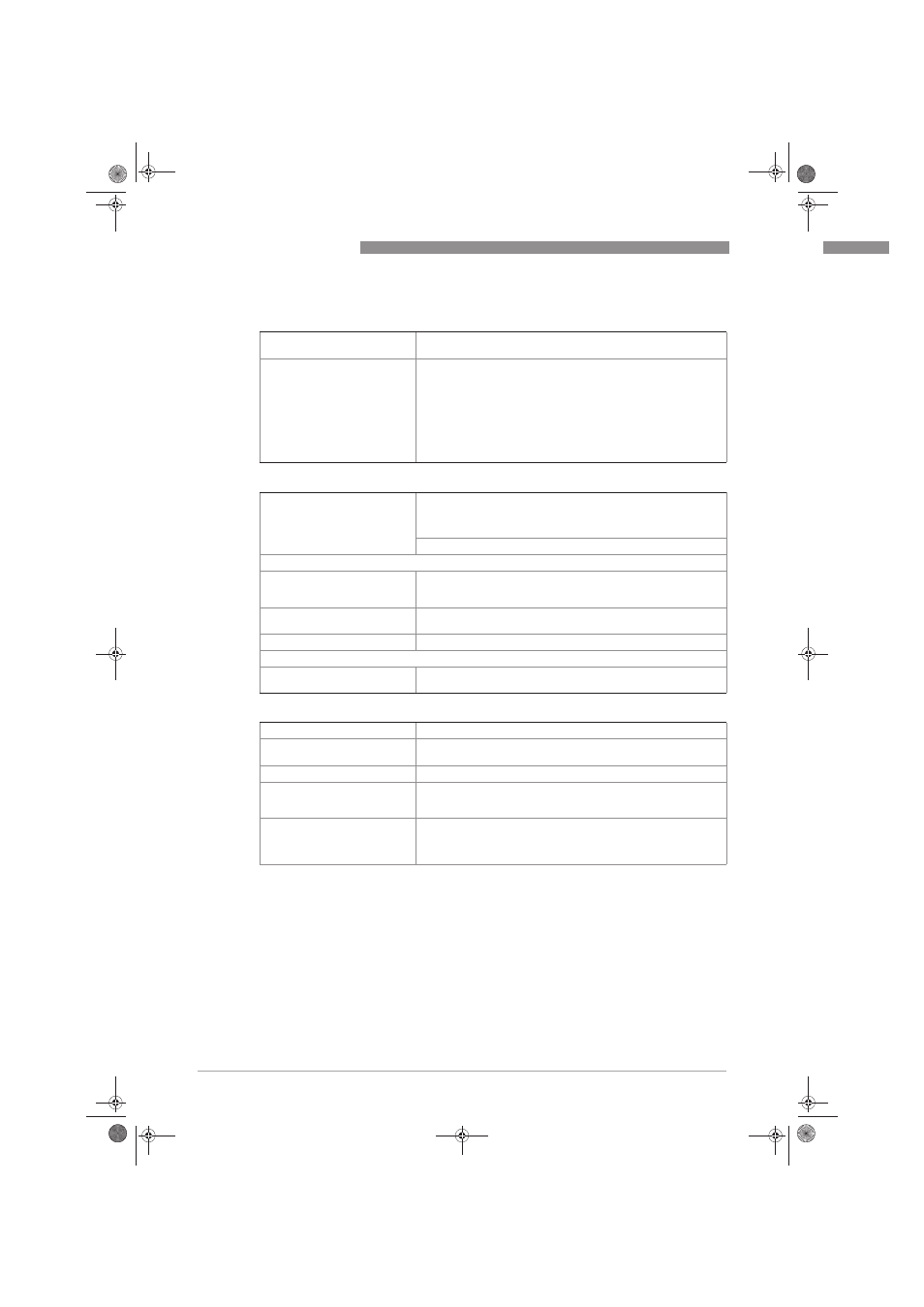

Measuring accuracy

Reference conditions

Ambient temperature: +23°C / +73.4°F (fluctuations due to air

pressure and density have no impact on measuring accuracy.)

Maximum measuring error

More detailed information in the subsection "Measurement Error"

(also in the "Technical Data" section). The maximum measurement

error also depends on the type of sensor:

•

Measuring insert with Pt100 RTD: measurement error in

accordance with tolerance classes A, B, 1/3 B and 1/10 B according

to DIN EN 60751.

•

Thermocouple: measurement error in accordance with tolerance

class 1 acc. to DIN EN 60584.

Operating conditions

Load limits

The load limits depend on several factors (e.g. dimensions, design

and material of thermowell). Other information can be found in the

"Installation" section or in separate subsections of section "Technical

data".

Thermometer without thermowell: 0.8...1.2 bara / 11.6...17.4 psia.

Temperature

Temperature

Temperature

Temperature

Process temperature

-200...+600°C / -328...+1112°F, depending on measuring insert,

design and material. Thermometer with thermocouple: Measuring

inserts without thermowell can be used up to 1100°C / 2012°F

Ambient temperature

-40...+100°C / -40...+212°F, depending on connection head and

measuring insert.

Storage temperature

-40...+70°C / -40...+158°F at 40...60% relative humidity.

Other conditions

Other conditions

Other conditions

Other conditions

Protection categories

Depends on the connection head and the cable gland used: IP 54

(BKK), IP 65 (BA, BUZ-T/S/H/HW, BVA), IP 67 (BGK), IP 68 (AXD)

Installation conditions

Insertion angle

90° to the flow, directly against or diagonally against the flow.

Insertion length

10...15 x thermowell diameter, minimum 100 mm / 3.94" (shorter

insertion lengths possible but they impair measuring accuracy).

Pipes with Ø ≤ 300 mm / 11.8"

The thermowell tip should project past the middle of the pipe.

Pipes with Ø > 300 mm / 11.8"

The thermowell tip may only project beyond the middle of the pipe

when the mechanical load permits and the thermowell is not excited

in its resonance; when in doubt, check the individual case again.

Bending radius

The immersion tubes on the measuring inserts can be bent but the

smallest bending radius must be at least 3 times the diameter of the

immersion tube.

Note: Do not bend the bottom 50 mm / 2"!

.backup.book Page 46 Tuesday, January 10, 2012 11:57 AM