4 calibration procedure—conductivity, Modbus registers—level sensor, 1 header registers – In-Situ Aqua TROLL 400 Modbus and SDI-12 Reference Guide User Manual

Page 43: Calibration procedure—conductivity, Header registers

5.4 Calibration Procedure—Conductivity

1. Write the Calibration Mode On command (0xE000) to the Sensor Command

register. Reading the actual conductivity parameter in calibration mode shall

present actual conductivity as AC

f

(the current cell offset and cell constant shall

not be applied).

2. Instruct the user to place the conductivity sensor into one or more conductivity

standards.

3. Read the actual conductivity and temperature parameters at each conductivity

standard.

4. Calculate new values for the cell offset K

0

and cell constant K and write these

values to their corresponding registers.

5. Write the Calibration Update command (0xE001) to the Sensor Command

register. The sensor sets the Last User Calibration Date to the current date and

sets the Next User Calibration Date to zero (none required).

6. Optionally, read the Last User Calibration Time register, add the next calibration

interval, and write the result to the Next User Calibration Time register.

7. Write the Calibration Off command (0xE002) to the sensor command register to

place the sensor in normal operation.

6. Modbus Registers—Level Sensor

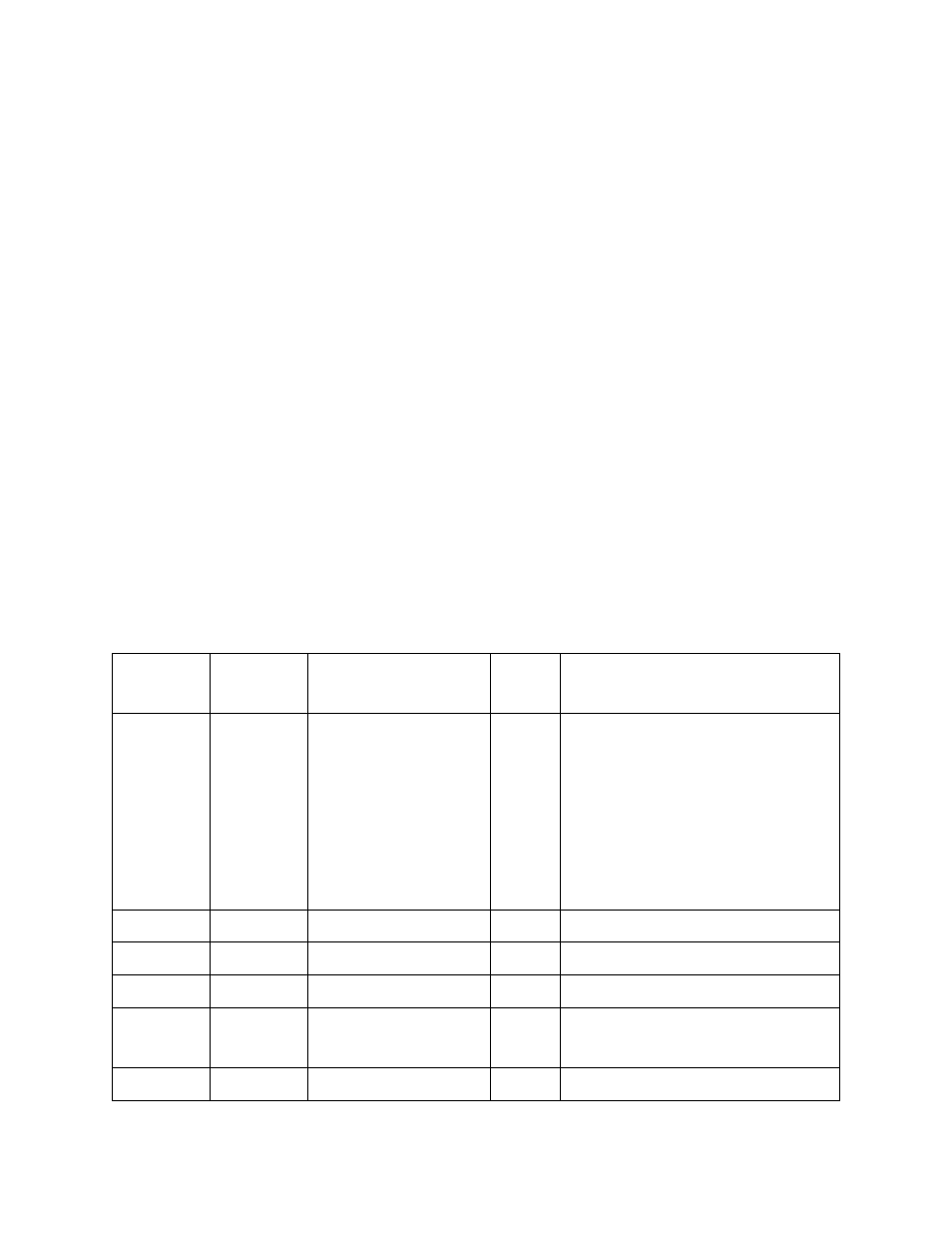

6.1 Header Registers

The sensor map data register offset points to the first register in the sensor data header block.

The current value for this sensor data register map version is 1.

Register

Size

(registers)

Mode & Access Level

(R/W)

Data

Type

Description

1001

1

R1/W4

ushort Sensor ID

34 = 30 foot full-scale level,

absolute pressure

32 = 100 foot full-scale level,

absolute pressure

33 = 250 foot full-scale level,

absolute pressure

1002

2

R1/W4

ulong

Sensor serial number

1004

1

R1

16 bits Sensor status

1005

3

R1/W4

time

Last factory calibration

1008

3

R1/W4

time

Next factory calibration

(0 = none required)

1011

3

R1

time

Last user calibration

43