2 how to clean cell, ଙଝ ଝ – Yokogawa IR200 User Manual

Page 78

7 - 9

IM 11G02M01-01E

7.5.2 How to clean cell

1. To clean the cell inside or infrared ray transmission window, first clear large dirt of it with a

soft brush and then wipe with soft cloth lightly.

Don’t use hard cloth.

Note) Handle the fragile window with care. Use care not to rub off the dirt from the

window roughly.

2. If the window or the cell interior is very dirty, use a soft cloth moistened with absolute

alcohol.

3. If the window is corroded, rub off the scale from the window lightly with a soft cloth to

which chrome oxide powder is applied. If it is excessively corroded, it should be replaced

with new one.

4. When cell or window cleaning is completed, assemble according to the cell disassembly and

assembly procedures. Especially, the pipe should be closely connected without gas leak, and

repair if the pipe is bent.

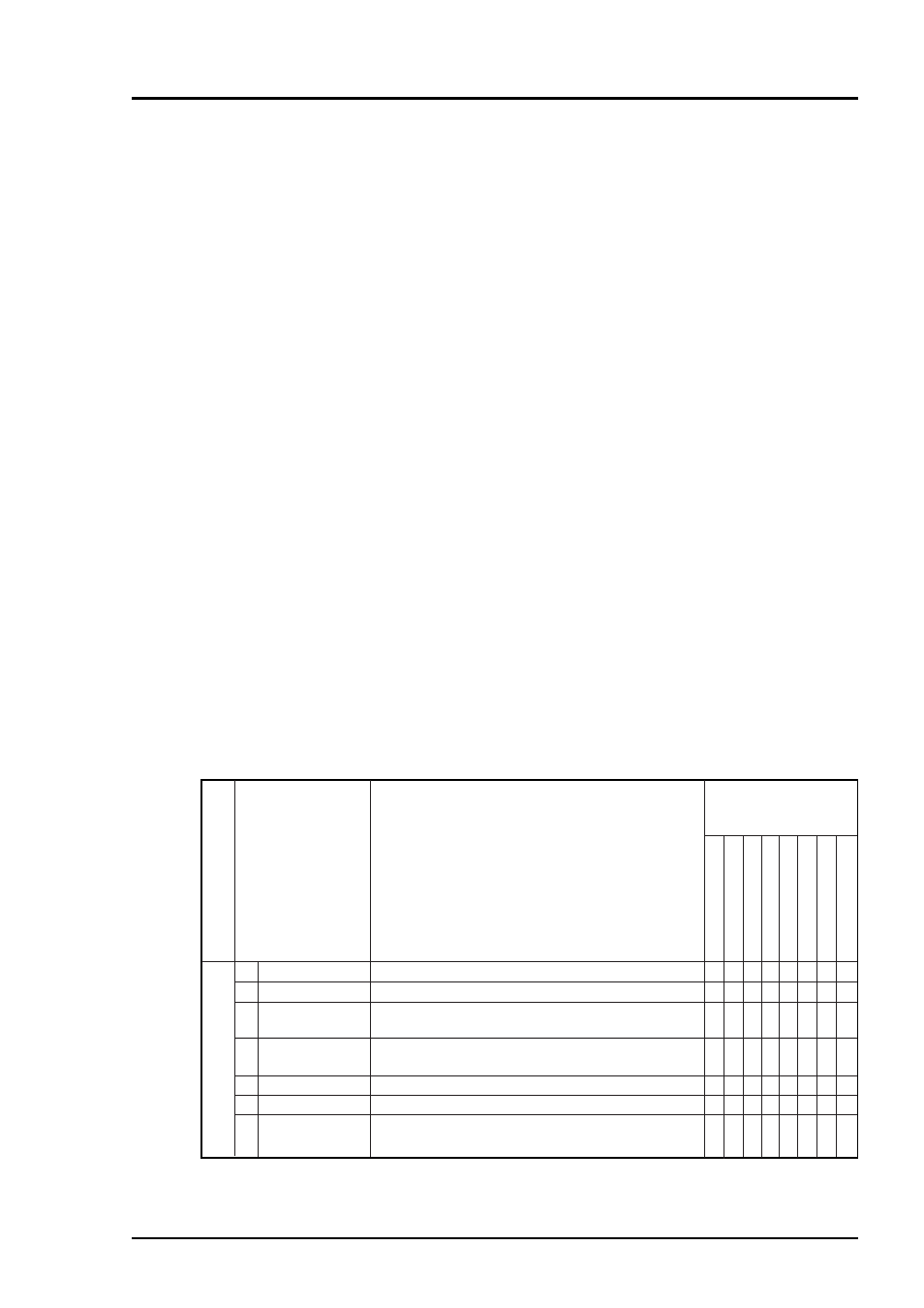

7.6 Inspection and maintenance of limited service-life components

The analyzer uses limited-life components. The recommended replacement periods are listed in

the below table.

1. Limited service-life components are those which wear out or for which failure is presumed

within five years under normal operating or storage conditions. Components with more than

five years of service life are the exception.

2. The previous table only involves the recommended periods for conducting preventive main-

tenance for limited service-life components; these periods do not guarantee that accidental

failures will not occur.

3. The recommended replacement preiods are tentative and depend on operating conditions.

4. The recommended replacement preiods may vary depending on the field date.

1. Light source

Recommended replacement period: Every five years (*1)

2. Sector motor

Recommended replacement periods: Every two years (*1)

3. Detector without

Recommended replacement period: Every five years (*1)

O

2

sensor

4. O-ring

Recommended replacement period: Every two years,

inspect it when cleaning of measuring cell. See Sec. 7.4

5. LCD panel

Recommended replacement period: Every five years (*1)

6. Power supply

Recommended replacement period: Every five years (*1)

7. Measuring cell

Set up an appropriate maintenance period

( by refering to the check results)

Checkpoint

Infrared gas analyzer

Check and

maintenance items

Procedure and criteria

Recommended check and

maintenance periods

Every five years

Every two years

Once a year

Every six months

Every three months

Once a month

Once a week

Routine

(*) In the check and maintenance columns, place a check mark (

᭺

) for check and confirmation work,

a dark star (

ଙ

) for replacement, and a white star (

ଝ

) for parts preparation for preventive maintenance.

(*1) These are seviceperson’s work, contact our sevicepersons.

ଙ

ଙ

ଙ

ଙ

ଝ

ଝ

᭺

᭺

T7.5E.eps