2 installation of analyzer, 3 piping, Caution – Yokogawa IR200 User Manual

Page 15

3 - 2

IM 11G02M01-01E

CAUTION

3.3 Piping

Caution on piping

In piping, the following precautions should be observed.

Wrong piping may cause gas leakage.

If the leaking gas contains a toxic component, there is a risk of

serious accident being induced.

Also, if combustible gas is contained, there is a danger of

explosion, fire or the like occurring.

• Connect pipes correctly referring to the instruction manual.

• Exhaust should be led outdoors so that it will not remain in

the locker and installation room.

• Exhaust from the analyzer should be relieved in the atmo-

spheric air in order that an unnecessary pressure will not be

applied to the analyzer. Otherwise, any pipe in the analyzer

may be disconnected to cause gas leakage.

• For piping, use a pipe and a pressure reducing valve to which

oil and grease are not adhering. If such a material is adhering,

a fire or the like accident may be caused.

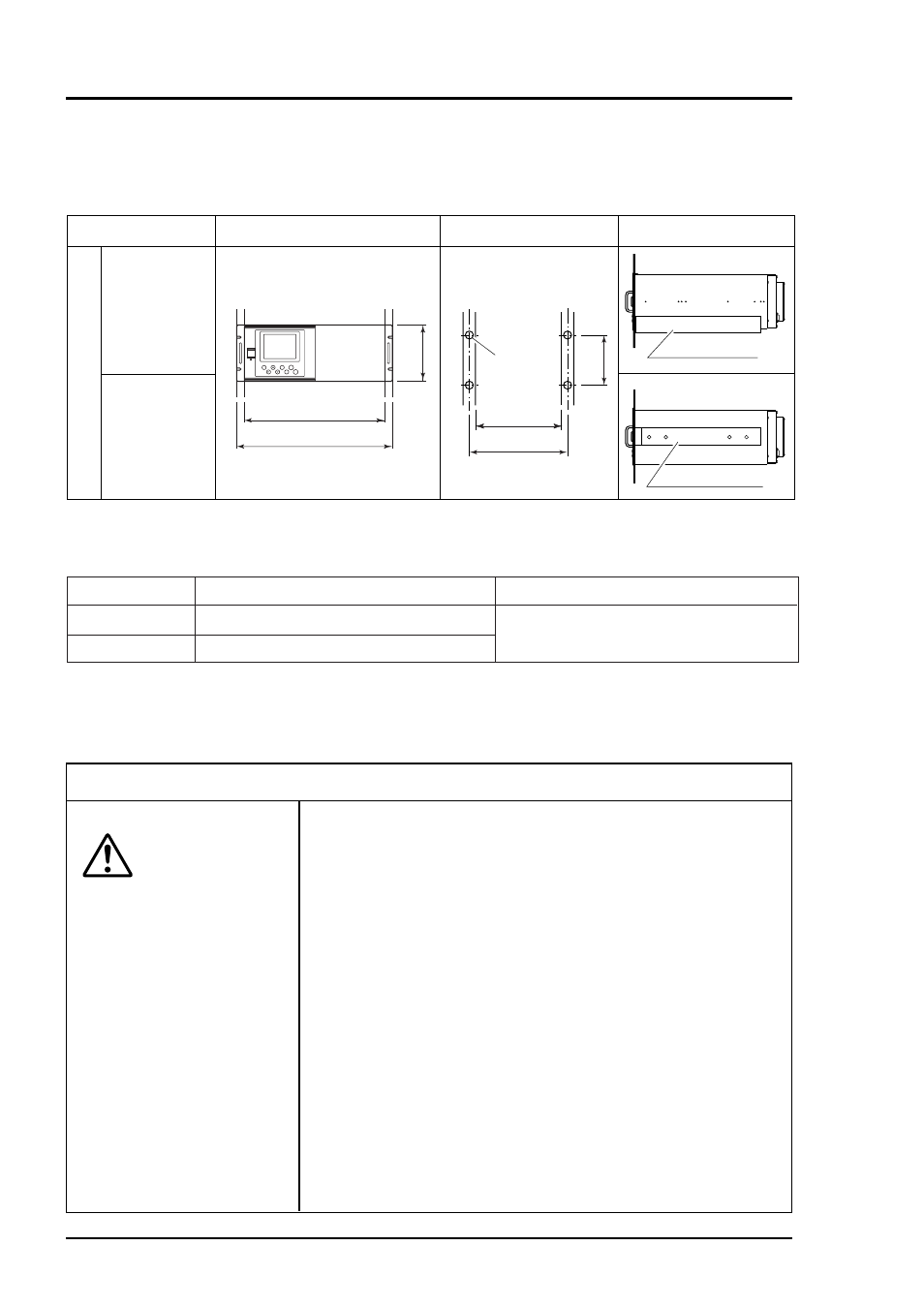

3.2 Installation of analyzer

There are two methods of installing the analyzer.

For detailed dimensions, see Chapter 9.3.

Types

Guide rail

Slide rail

External dimensions

483

Mounting dimensions

Mounting method

(Unit:mm)

INFRARED GAS ANALYZER

SPAN

ZERO

ENT

ESC

POWER

MODE

429

177

465

M6

Guide rail

101.6

Slide rail

19 inch rack mounting (Note)

450 or more

Note) The mounting method should be selected to meet the installation requirements since the top

cover must be detached from the gas analyzer for maintenance and check.

Mounting method

Slide rail

No maintenance space is provided at the top.

Guide rail

Maintenance space is provided at the top.

Conditions

Recommended slide rail: 305A-20, Accuride International Inc.

Remarks

These methods must be rigid enough to

withstand the mass (about 10 kg) of the gas

analyzer.