Maintenance, 1 daily check, 2 daily check and maintenance procedures – Yokogawa IR200 User Manual

Page 70

7 - 1

IM 11G02M01-01E

7. MAINTENANCE

7.1 Daily check

(1) Zero calibration and span calibration

1.

It is used for zero point adjustment. For calibration, refer to 6.9.1, Zero calibration.

2.

After zero calibration, perform span calibration. For calibration, refer to 6.9.2, Span calibra-

tion.

3.

Zero calibration and span calibration should be performed once a week, if required.

(2) Flow check

1.

Sampling gas flow rate and purge gas flow rate should be as follows;

Sampling gas flow rate: 1.0

±

0.5L/min (stable)

Purge gas flow rate:

About 1L/min

2.

Maintenance and check should be carried out every day, if required.

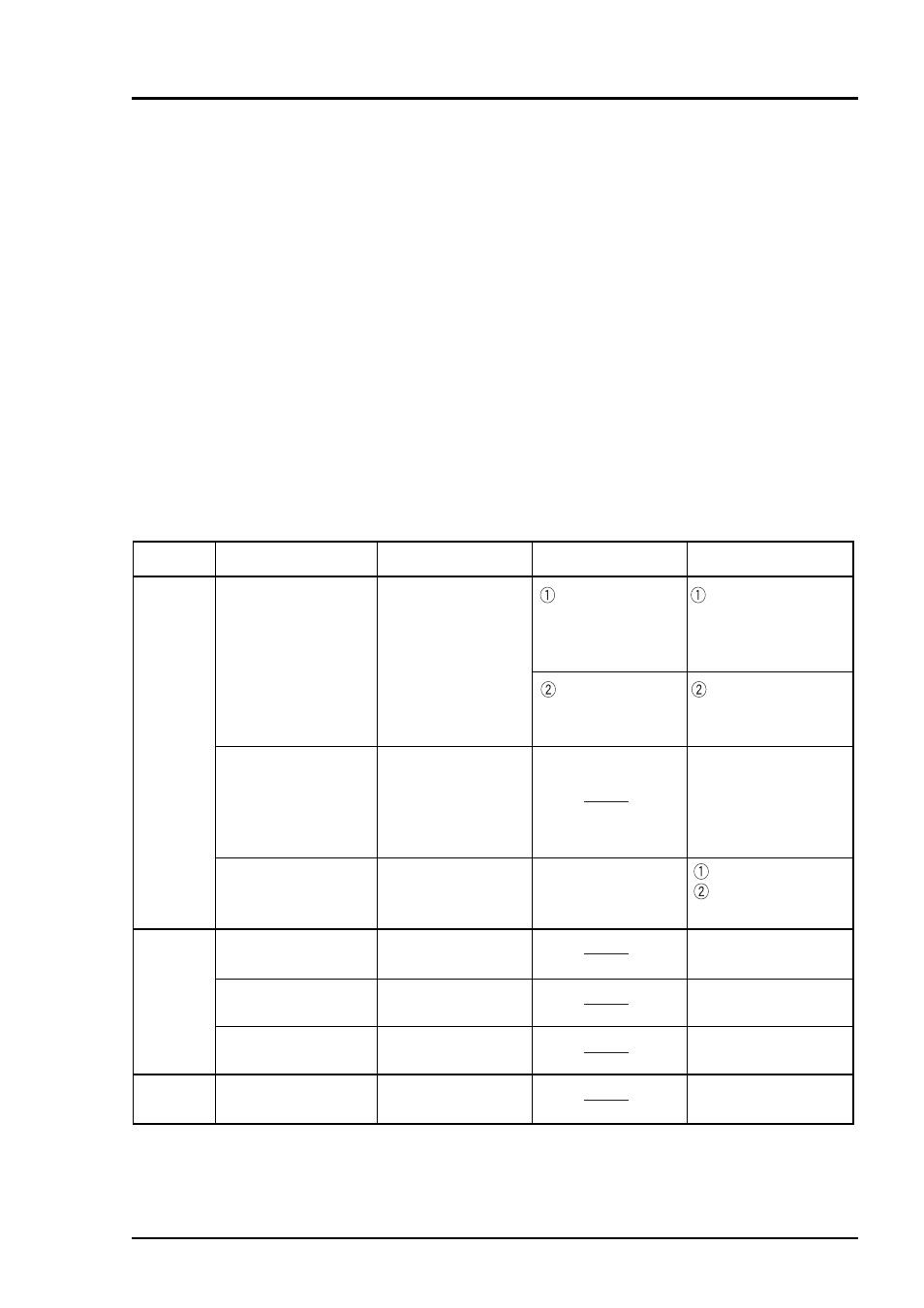

7.2 Daily check and maintenance procedures

Table 7-1 Maintenance and check list

Dust is mixed in the

sample cell.

Standard flow rate is

1L/min. It is not within

the range of the

specified flow rate of

0.5 to 1.5 L/min.

Much clogged

Out of zero point

Out of the span

point

Irrespective of

phenomena

Irrespective of

phenomena

Lower indication

Replacement of Monitor

filter (membrane filter)

Zero point of gas

analyzer

Span point of gas

analyzer

Replacement of monitor

filter (membrane filter)

Every week

Every day

Every year

Gas analyzer

Recorder indication

Air is sucked in

anywhere in the

sampling tube.

Primary filter is

damaged.

Overhaul.

Replace filter (paper).

Span calibration

Zero calibration

Adjust the flow rate with

flow rater needle valve.

Replace primary filter.

Replace filter

(filter paper).

Check for leak of

the sampling line

and repair, if required.

Clean sampling cell

and check for

sampling device,

especially gas filter.

Remedy

Cause

Phenomena

Parts to be checked

Check for purge gas

flow if purging the

sampling gas flow

instrument.