A2.4 setting the ai2 function block, A2.5 setting the transducer block – Yokogawa EJA115 User Manual

Page 48

IM 01C22T02-01E

A-10

APPENDIX 2. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS

A2.4 Setting the AI2 Function

Block

The AI2 function block outputs the static pressure

signals.

(1)Setting the static pressure information

The static pressure range and output range can be

set using the same procedure as is used for the AI1

function block. For details of how to set these

values, refer to “Setting the AI1 function block” in

Appendix 2.3.

A2.5 Setting the Transducer

Block

To access function specifics of the EJA of the trans-

ducer block, the DD (Device Description) for EJA

needs to have been installed in the configuration tool

used. For integration of DD, refer to “Integration of

DD” in Section 4.4.

(1)Setting the LCD display

Access the DISPLAY_MODE parameter and

set the unit of display.

FA0208.EPS

1: Engineering Unit (Engr. Unit)

2: %

3: 1/10 @ Engr. Unit

4: 1/100 @ Engr. Unit

5: 1/1000 @ Engr. Unit

6: 1/10000 @ Engr. Unit

7: 1/1000000 @ Engr. Unit

Access the DISPLAY_CYCLE parameter and

set display cycle.

The display cycle is 300 mS x (setting).

It defaults to 1, but if the LCD display looks

unclear when used in lower temperature

environments, increase the value as required.

(2)Setting the unit of temperature

FA0209.EPS

Access the TERTIARY_VALUE parameter.

Set the temperature in the following units:

1001 =

°

C

1002 =

°

F

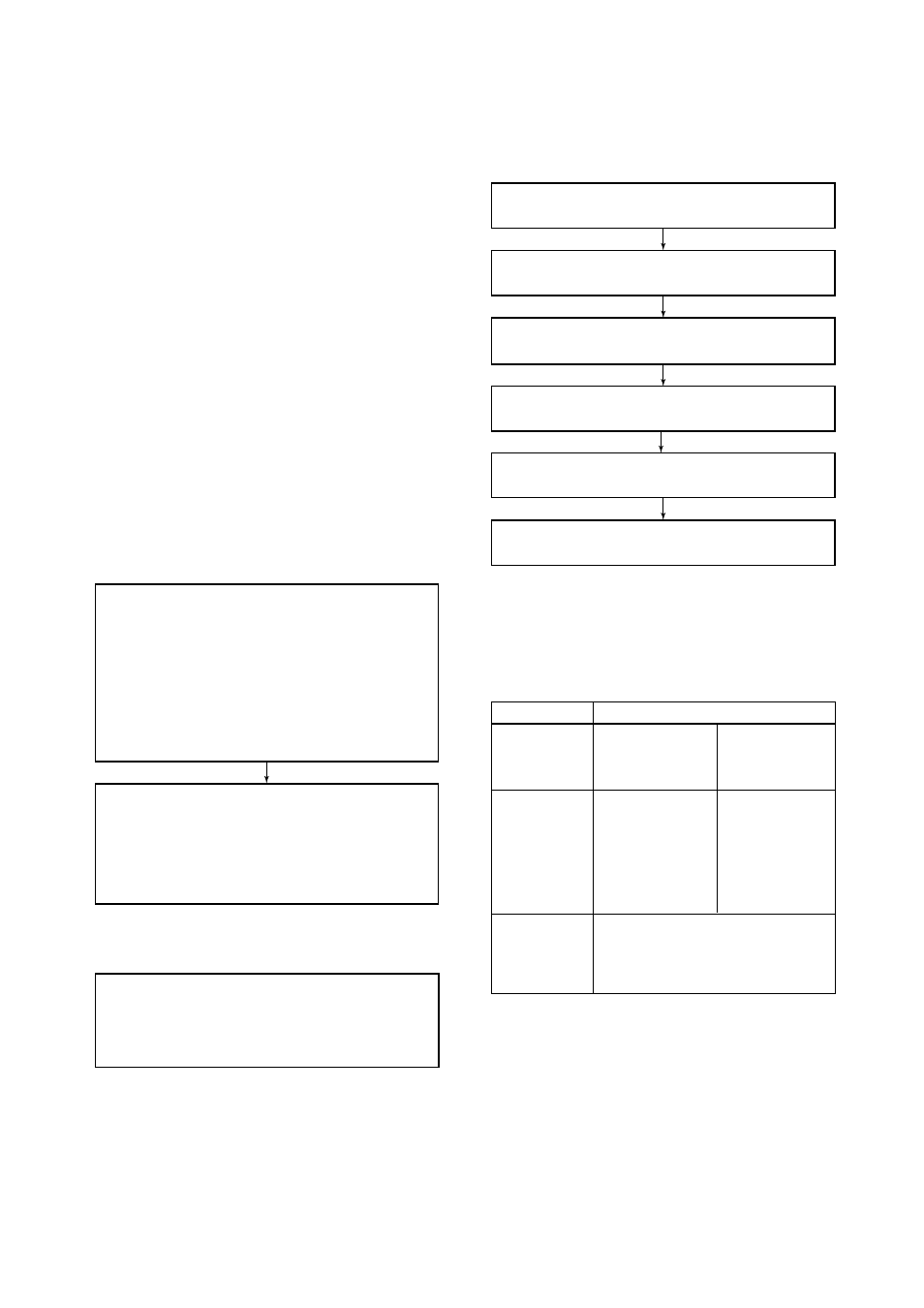

(3)Range change while applying actual inputs

It is possible to calibrate the sensor by applying the

actual inputs to low-pressure and high-pressure

points.

Apply the pressure to the high-pressure point

from the pressure reference tool.

Access the CAL_POINT_LO parameter.

Write the pressure value being applied in Pa.

FA0210.EPS

Access the CAL_POINT_HI parameter.

Write the pressure value being applied in Pa.

Apply the pressure to the low-pressure point

from the pressure standard.

Access the TRIM_MODE parameter.

Set Trim enable

Access the TRIM_MODE parameter.

Set Trim disable

(4)Zero-point adjustment

Zero-point adjustment can be performed in various

ways.

Choose the optimum method in accordance with the

circumstances specific to the application employed.

TA0203.EPS

Adjustment

Summary

Zero-point

adjustment

using setting

tool.

(a) Set the current

input value to 0%.

Zero-point

adjustment using

an external zero-

point adjustment

screw.

(c) Perform zero-adjustment with the zero-

point adjustment screw attached to the

transmitter.

Set the input signal

to 0% status and

adjust 0% output.

(b) Adjust the output

to a reference

value obtained

using other

means.

If it is difficult to set

input signals such

as tank level to 0%

status, adjust the

output to a

reference value

obtained using

other means.